A few years ago, on a tour of Land Rover’s production facility in Solihull, I witnessed first-hand the vast differences between the latest 21st century vehicle manufacturing technologies and some rather old-school manufacturing methods dating back to the middle of the 20th century.

In one of Solihull’s massive buildings, I saw the separate chassis and body sections of Discovery 4s and Range Rover Sports swishing around on automated tracks before meeting and being bolted together by robotic machinery in a matter of seconds.

In another building, I gazed in wonderment at the incredible power of a machine that stamped the huge aluminium body sections of the then-new Range Rover. And then I entered a hall where Defender production took place.

It was like a time warp. Instead of frantic robots melding big and complex components in the blink of an eye, there were blokes in green overalls wielding spanners and rivet guns, carefully and methodically putting vehicles together by hand. As a result, the Defender production line ran at a far slower pace than that of the more modern Land Rovers rolling out of the building next door.

It was like a time warp. Instead of frantic robots melding big and complex components in the blink of an eye, there were blokes in green overalls wielding spanners and rivet guns, carefully and methodically putting vehicles together by hand. As a result, the Defender production line ran at a far slower pace than that of the more modern Land Rovers rolling out of the building next door.

This outdated manufacturing technology is one of the reasons why, after an incredible 67 years, Defender production is coming to an end. Sure, another reason is that Land Rover has been unable (or unwilling) to modernise the current Defender design to meet current and future safety and emission standards, but the labour-intensive (and therefore expensive) production line is certainly a strong factor.

1947: In the beginning

Unless you’ve been hiding under a rock, you’d have heard the story about Rover’s then-technical chief Maurice Wilks sketching the first Land Rover in 1947 on the sands of Red Wharf Bay on his farm at Newborough, Anglesey, Wales.

He was inspired, supposedly by a question posed by his brother Spencer, then-managing director of Rover, who asked Maurice what he would do when his old army surplus Jeep wore out.

The pair then became intent on building a multi-purpose, go-anywhere vehicle that Rover could export to boost the company’s post-war output. Ironically, a Jeep chassis was used underneath the first prototype.

The pair then became intent on building a multi-purpose, go-anywhere vehicle that Rover could export to boost the company’s post-war output. Ironically, a Jeep chassis was used underneath the first prototype.

That prototype featured a centre-mounted steering wheel (so it would be suitable for use in left and right-hand-drive markets) and was painted in military-surplus cockpit paint, of which there was plenty after WWII.

By the time the vehicle was unveiled at the Amsterdam Motor Show in 1948, the centre-steering had been flicked in favour of a more traditional set-up. The Land Rover Series I featured its own unique box-section galvanised steel chassis on which was mounted a very simple sheet-aluminium body – steel was hard to come by but aluminium was plentiful as aircraft production wound down after the war.

The engine was Rover’s existing pre-war design 1.6-litre four-cylinder petrol unit with overhead inlet and side exhaust valves, mated to a four-speed gearbox and a two-speed transfer case, and a permanent four-wheel drive system.

The engine was Rover’s existing pre-war design 1.6-litre four-cylinder petrol unit with overhead inlet and side exhaust valves, mated to a four-speed gearbox and a two-speed transfer case, and a permanent four-wheel drive system.

Adding to the vehicle’s versatility, power take-offs (PTOs) were fitted to enable the Land Rover to be used as a stationary power unit, and early marketing brochures often showed various pieces of farming equipment attached to the vehicle.

The simplicity and robustness of the Series I proved hugely popular, with the Land Rover going on to become a British manufacturing success story that far exceeded initial expectations. In the first year of production, just 3048 Land Rovers were built, but that rose to 8000 in 1949 and by 1950 that jumped to 16,000.

Over the next few years the Land Rover slowly evolved; the permanent four-wheel drive was replaced in 1950 with a system that allowed drivers to select two or four-wheel drive in high range. The Series II was introduced in 1958, followed by the Series IIA in 1961 and the Series III in 1971. By this point, the engine options included 2.25-litre petrol and diesel fours, while a little later, a 2.6-litre petrol six was introduced.

Over the next few years the Land Rover slowly evolved; the permanent four-wheel drive was replaced in 1950 with a system that allowed drivers to select two or four-wheel drive in high range. The Series II was introduced in 1958, followed by the Series IIA in 1961 and the Series III in 1971. By this point, the engine options included 2.25-litre petrol and diesel fours, while a little later, a 2.6-litre petrol six was introduced.

By 1976, one million Land Rovers had been produced and the vehicle was now significantly improved from the original design, with two wheelbase options (up from the original 80-inch model to 88-inch and 109-inch models) and a huge variety of body variants. But the essence of the first Land Rover was still clearly visible in the vehicle’s design and underpinnings.

1979: Coil revolution

In 1979, Land Rover introduced a V8 version of the Land Rover that featured a flat grille. The designers couldn’t have known it at the time, but this simple styling change (albeit with a revised grille) would see the Defender through to the end of its production some 36 years later.

Land Rover had gained plenty of experience with long-travel coil spring suspension with the introduction of the Range Rover to its line-up in 1970, and this technology was applied to the Land Rover in March 1983 with the launch of the 110. The following year, the coil-spring 90 (actually on a 93-inch wheelbase) variant was introduced.

Land Rover had gained plenty of experience with long-travel coil spring suspension with the introduction of the Range Rover to its line-up in 1970, and this technology was applied to the Land Rover in March 1983 with the launch of the 110. The following year, the coil-spring 90 (actually on a 93-inch wheelbase) variant was introduced.

These models were available with a choice of 2.5-litre diesel, 2.25-litre four-cylinder and 3.5-litre V8 petrol engines. An extended-wheelbase variant (the 127) was also introduced, and the petrol four was given an increase in capacity to 2.5 litres.

The Defender nameplate was finally introduced in 1990, at which time the vehicle was equipped with the same 2.5-litre turbo-diesel engine (200Tdi) used in the Discovery, which had been introduced a year earlier.

The Defender nameplate was finally introduced in 1990, at which time the vehicle was equipped with the same 2.5-litre turbo-diesel engine (200Tdi) used in the Discovery, which had been introduced a year earlier.

In the early 1990s, production of the Land Rover had decreased significantly due to increased competition from around the world (most notably Japan), but in July 1993 the Defender range celebrated another sales milestone: the 1.5 millionth vehicle sold since production began in 1948.

2000: Defender evolution

Over the next three decades, production of the Defender plodded along at the Solihull plant in much the same way as it always had, while other Land Rovers such as the Range Rover and Discovery would undergo revolutionary revamps.

All-new models, including the Freelander and Range Rover Sport, would also be introduced. Nevertheless, Land Rover managed to ‘evolve’ the Defender just enough over the years to keep it relevant – and compliant – with much of the world’s emissions standards.

All-new models, including the Freelander and Range Rover Sport, would also be introduced. Nevertheless, Land Rover managed to ‘evolve’ the Defender just enough over the years to keep it relevant – and compliant – with much of the world’s emissions standards.

The 200Tdi engine was replaced by the 300Tdi in 1995, with various changes including Bosch electronics. Then the Td5 with Electronic Unit Injection came along in 1998.

The Defender Xtreme (as it was marketed in Australia) scored electronic traction control from 2000 and then, in 2007, a 2.4-litre Ford turbo-diesel engine replaced the Td5.

The Defender Xtreme (as it was marketed in Australia) scored electronic traction control from 2000 and then, in 2007, a 2.4-litre Ford turbo-diesel engine replaced the Td5.

In the same year, the Defender’s interior received a much-needed upgrade, with an all-new dash that incorporated a much more efficient air conditioning system, while the flip-up air vents below the windscreen were scrapped. The current 2.2-litre four-cylinder turbo-diesel engine was introduced in 2012.

Land Rover in Australia

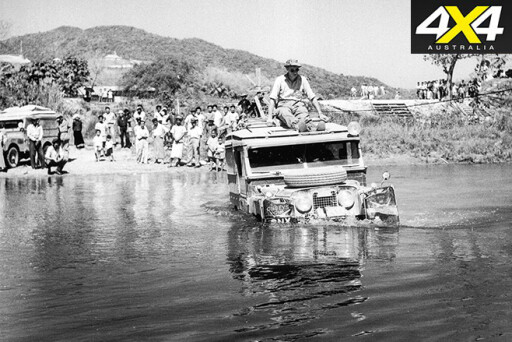

The first Land Rovers to land in Australia arrived towards the end of 1948, which also marked the first year of the vehicle’s production. Land Rovers played a big part in Australia’s largest engineering project, the Snowy Mountains Hydro Electric Scheme, and by the mid-1950s there were more than 800 Land Rovers being used on the project.

Land Rover was also pivotal in opening up vast parts of inland Australia. Explorer Len Beadell used Land Rovers to open up routes such as the Gunbarrel, Connie Sue and Anne Beadell highways.

The Australian Army has been a huge Land Rover customer for many years. While it ran a small number of Series I Land Rovers, the fleet grew significantly with the introduction of the Series II. The ADF also took delivery of Series III models, powered by a 2.6-litre six-cylinder petrol engine.

The Australian Army has been a huge Land Rover customer for many years. While it ran a small number of Series I Land Rovers, the fleet grew significantly with the introduction of the Series II. The ADF also took delivery of Series III models, powered by a 2.6-litre six-cylinder petrol engine.

Throughout the 1960s and 1970s Australian-market Land Rovers were built in a manufacturing facility in the Sydney suburb of Enfield, while in the 1980s Australian Army Perentie Defenders were manufactured at Jaguar Land Rover Australia’s (JRA) Liverpool plant in western Sydney.

The Australian Army is only now replacing its fleet of Land Rover Defenders, and if you want your own slice of Aussie Land Rover history you can pick one up through specialist auction houses.

The Australian Army is only now replacing its fleet of Land Rover Defenders, and if you want your own slice of Aussie Land Rover history you can pick one up through specialist auction houses.

2015: The end game

The final Limited Edition Land Rover Defenders to roll off the Solihull production line pay homage to the model’s long and distinguished history; they are the Autobiography, Heritage, and the Adventure (pictured l-r above).

The Heritage Limited Edition is, according to Land Rover, “designed in the spirit of the original 1948 Land Rover, brought up to date with modern design and engineering”. It’s painted in classic Grasmere Green, inspired by the original post-WWII RAF surplus paint applied to the first Land Rover. It even pays tribute to that vehicle by wearing HUE 166 graphics that recall the original vehicle’s registration plates.

As well as a number of unique styling cues and special features, the Adventure Limited Edition features special graphics and additional underbody protection plates, while the Autobiography has boosted power and torque outputs as well as a host of luxury appointments including a “Full Windsor leather environment”.

As well as a number of unique styling cues and special features, the Adventure Limited Edition features special graphics and additional underbody protection plates, while the Autobiography has boosted power and torque outputs as well as a host of luxury appointments including a “Full Windsor leather environment”.

While there have been many rumours regarding a possible replacement for the Defender, Land Rover has remained tight-lipped on the subject.

A concept vehicle called the DC100 was unveiled at the 2011 Frankfurt Auto Show but, since then, Land Rover design director Gerry McGovern has been quoted as saying a new Defender will bear little resemblance to that concept.

Ups and downs

While Defender production has plodded along reliably for 67 years, the same can’t be said for the company that manufactures this iconic vehicle.

Land Rover was a part of the Rover Company when it was conceived in 1948. Rover became a part of British Leyland in 1975, and then in 1978 Land Rover Limited was established as a separate subsidiary, completely taking over the Solihull production facility in 1982.

The British Government, which owned British Leyland, was keen to offload the company to General Motors in 1986, but the deal never went through due to public and parliamentary outrage. The company was renamed the Rover Group and was sold to British Aerospace in 1988.

In 2008, Indian company Tata Motors bought Jaguar and Land Rover from Ford, and formed the Jaguar Land Rover (JLR) company. So far Tata Motors has given JLR free rein in the design and development of new models, and this has proved to be an extremely successful and profitable business decision. The company was reported to have sold a record 425,006 vehicles in 2013.

COMMENTS