As an important resource for aircraft engineers, race teams and automakers, wind tunnels have never been so important – especially in the age of electrification for the vehicle industry.

However, limitations associated with size and the exorbitant costs involved with developing and maintaining wind tunnels meant UK-based company Totalsim had to put its thinking hats on.

As reported by Autocar, Totalsim – which specialises in computational fluid dynamics (CFD) modelling – has worked out a way to switch up the traditional wind tunnel process.

Rather than having a stationary vehicle surrounded by moving air, there would instead be a moving car speeding through stationary air.

To achieve this feat, the company looked into repurposing dormant railway tunnels in the United Kingdom back in 2013.

As luck would have it, founder Rob Lewis and his crew stumbled across the Catesby Tunnel, located near the English town of Daventry, within the boundaries of the famous ‘motorsport valley’ – an area home to various Formula One teams and the Silverstone Circuit.

The 2.7-kilometre long railway tunnel was soon acquired, with work commencing on transforming it into an aerodynamic testing centre. Eight years and around $37 million Australian dollars later, the tunnel is close to reopening to serve various manufacturers, race teams and other clients.

Completed in 1897 following two years of construction, the tunnel was built at the insistence of Henry Attenborough, owner of the Catesby Estate, who stated the train line should move underground to prevent ‘unsightly trains’ passing through the landscape. After 68 years in service, the tunnel was retired in 1966 as a result of the Beeching Axe, which worked to modernise the national railway system in Great Britain.

Sidelined for almost half a century, years of development work resulting from its purchase in 2013 included the draining of water, cleaning of soot-covered vents and minor restoration of the structure. To the surprise of Totalsim, the tunnel floor was found to be both almost perfectly flat and straight, with a slight 1:176 (0.006 per cent) gradient.

“We were amazed when we actually scanned it,” said Jon Paton, leader of aerodynamics at Totalsim. “It’s within a couple of centimetres of being perfect.”

Final works include a new concrete base, which is being laid with an ‘ultra-precise’ coating to establish a consistent surface without any gaps or expansion joints.

“The most important thing for testing is consistency and repeatability,” he added. “That’s where high-quality data comes from.”

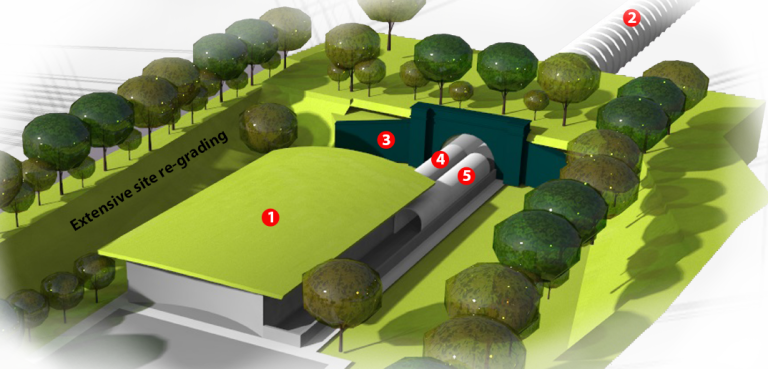

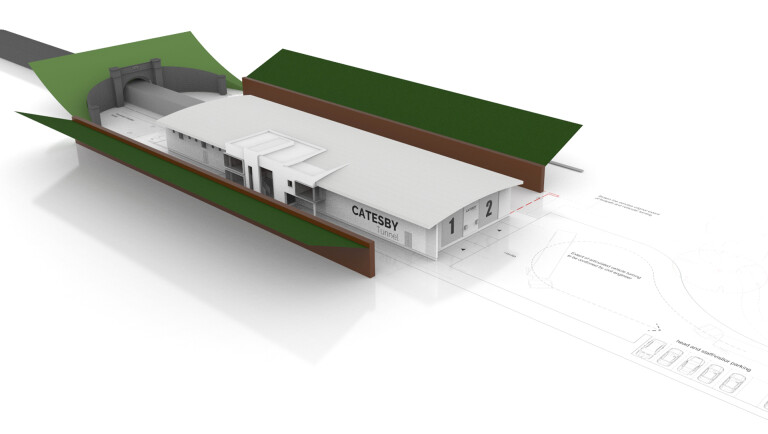

A research and development station has also been built alongside the redeveloped tunnel, based on the design of a Victorian-era engine shed and station yard. This facility will allow automotive manufacturers, suppliers and researchers to work together in one location to focus on collaborating and innovating on testing and design for vehicles.

The research and development facility and wind tunnel are covered by a large passageway, helping to ensure confidentiality in top-secret aerodynamic testing.

In addition to restoring the tunnel, the company has also installed turn-tables at each end to help vehicles return to the base without the expert moves that would typically be required in such a tight space.

With initial clients expected to include Mercedes-Benz, Jaguar Land Rover and Mini, as well as five Formula One teams – Alpine, Williams, Red Bull, Mercedes-Benz and Aston Martin – the facility will be a busy place when it opens for business in November.

COMMENTS