Geely isn’t mucking around. The Chinese automotive conglomerate has managed to curtail the COVID-19 (coronavirus) outbreak in its home facilities ever since it started, and to date can claim that none of its employees has contracted the virus.

It’s all thanks to aggressive quarantine, distancing and cleaning measures that have allowed Geely to return to full working capacity while other automotive manufacturers are actively shuttering their factories worldwide.

To combat the outbreak, Geely – who owns car brands like Lotus and Volvo, and is one of China’s biggest car builders – first started by extending the Chinese New Year holiday from late January until mid-February, allowing those who could work, to work from home.

More coronavirus news

- Live rolling coverage of the Covid-19 impact

- How to minimise COVID-19 exposure in your car

- Industry reels from coronavirus as Elon Musk scoffs

- Industry shutting down as car sales tank

As of March 1, all of Geely’s Chinese operations are now back on track – albeit with strict new protocols in place. All international business travel was banned, and all guests to the company have been refused entry.

All employees must undergo temperature testing in makeshift tents situated outside the factory on the way into work, and clock-in and clock-out machines have been moved outside of main buildings to ease congestion.

Those arriving to work by car must have their temperature taken too, before driving over sanitized mats to rid any bacteria from the underside of the car. During the day, cleaning teams whip around the car park wiping down exterior door handles and touch-points of employees’ cars.

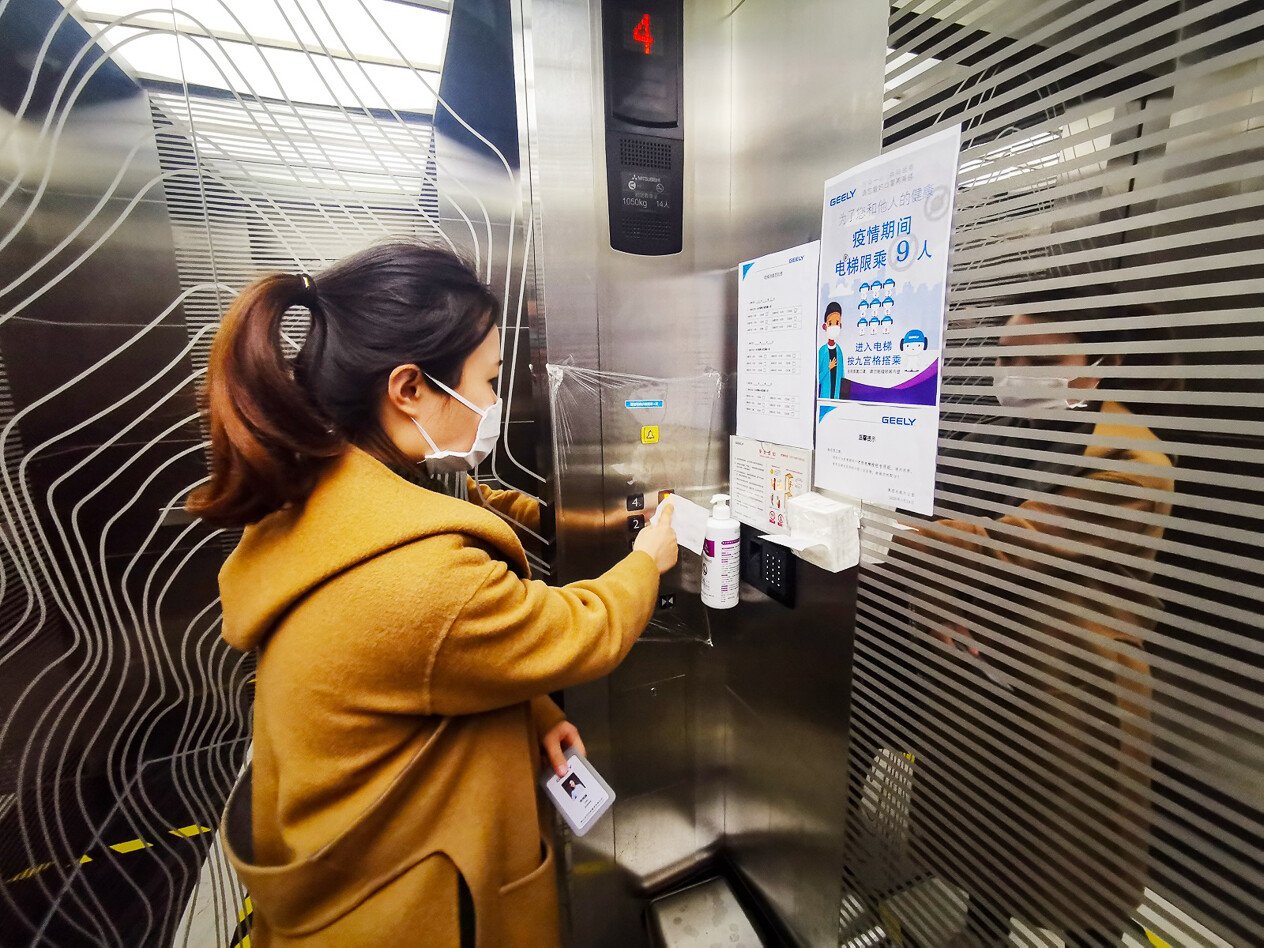

Hand sanitiser was distributed throughout major traffic areas in buildings, and there are even limits on the number of people that can share elevators.

Geely even has a policy for people queueing for printer machines, who must stand one metre apart in an orderly fashion.

All employees are given face masks which they must change every eight hours, and floor supervisors check everybody’s temperatures twice a day.

Large meetings have been cancelled and video conferencing replaces face to face interactions.

One person per square in a Geely elevator

Some of these measures might sound drastic, but they’ve enabled the Geely Group’s 60,000 employees to return to work across China with no coronavirus cases to date.

This comes at a time when factories including Honda, BMW and Toyota opted to close their doors in the UK, while GM, Ford and FCA temporarily shut their factories in the US.

An FCA factory in Italy that produces commercial vehicles has been hastily reset to allow for more space between workers, but most facilities in the world are shuttered.

For those who haven’t closed just yet, British prime minister Boris Johnson has called on manufacturers like Rolls-Royce, Airbus and Jaguar Land Rover to make 20,000 much-needed respirators from scratch in two weeks. The UK’s current number of ventilators is 5000, but this will not be enough.

Rolls-Royce has also announced that it is closing its Goodwood factory for two weeks.

Learnings need to be taken from those companies like Geely that is actively stemming the spread of coronavirus by introducing meaningful protocols.

If carmakers across the globe can introduce a similar system, that would ensure the automotive industry is in a much stronger position going forward.