A growing appetite for lightweight alloys has sparked a shortage of aluminium in the US, where almost all production capacity has been consumed by just one industry – carmaking.

According to Tom Boney, the vice-president of Novelis – one of the world’s largest suppliers of aluminium sheetmetal -- carmakers are accounting for the lion’s share of the metal.

“The industry is very close to capacity, and more capacity will be required,” Boney said.

What’s driving this demand? Tightening emissions laws mainly, with even utilitarian cars such as the Ford F-150 pickup now using aluminium for its cabin and tub to help keep weight – and fuel use – low.

It appears to be a growing trend. The replacement for the rugged Jeep Wrangler off-roader looks to be taking a leaf from the book of the recently decommissioned Land Rover Defender, as it is expected to use an aluminium “top hat” sitting on a traditional steel ladder-frame chassis.

But as construction techniques improve and the cost of using lightweight alloys in mass-produced cars drops, many carmakers are chasing aluminium for another reason - performance.

By saving weight through swapping steel for aluminium, cars need less power to perform at the same level as a heavier steel-based car. Acceleration, braking and handling all benefit, and when those improvements are coupled with a reduced thirst for fuel it becomes especially attractive to a carmaker.

One other advantage? Aluminium doesn’t rust.

One of the companies supplied with aluminium by Novelis is Jaguar Land Rover, which has made itself a leader in this field by pioneering new methods of construction that made aluminium more mass-production friendly.

Jaguar’s F-Type, F-Pace, XE and XF are built atop an aluminium architecture, while the Ranger Rover and Range Rover Sport also feature extensive use of alloy chassis components. The next-generation Discovery is also expected to make a jump to the lighter metal.

“We made the most aluminium cars in the world last year of any manufacturer,” said Jaguar Land Rover’s chief of lightweight chassis technology, Mark White.

“We’ve really worked on speeding up the production techniques. When we first started it would take six seconds to do a rivet; it now takes us less than a second.”

Taking advantage of aluminium’s high recyclability (it can be melted down and reformed repeatedly with little degradation, unlike paper and many plastics), Jaguar Land Rover also incorporates a high proportion of scrap aluminium in its new cars. Is the can of beer in your hand destined for a more glamorous life as a high-end automobile? Quite possibly.

LIGHT METAL

Supply issues notwithstanding, aluminium is set to become commonplace in cars of the future. But what about the here and now? Here’s a list of some of the cars currently on the market that make an extensive use of aluminium:

Audi TT

The Audi TT may be built on a steel floorpan, but virtually every metal panel you see from the outside is made of aluminium. There are also a number of aluminium extrusions, pressings and castings lurking underneath. Result? A relatively svelte 1300kg kerb weight

Audi A8

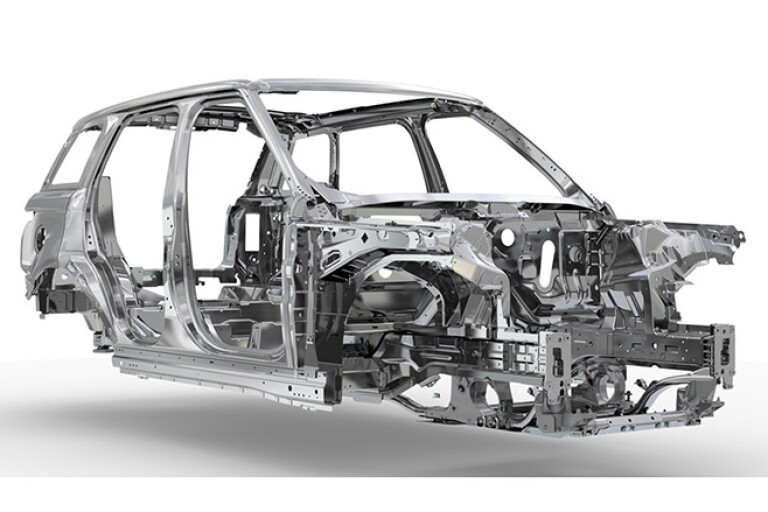

Audi’s A8 has employed an aluminium-heavy construction for three generations now, helping it reduce the mass of its “body in white” – the car without any bits bolted onto it -- and allowing more mod-cons to be fitted without hurting performance, handling or economy. Audi claims the A8 is the lightest AWD luxury car in its size class.

Jaguar XE

The Jaguar XE medium sedan is built on Jaguar’s box-fresh lightweight platform, with a bare bodyshell roughly 80 percent alloy. Not only is the bulk of the XE’s chassis made from aluminium, but Jaguar uses the metal in most of the car’s suspension links to improve handling performance.

Lamborghini Huracan

The Lambo Huracan shares the bulk of its aluminium space frame chassis with the Audi R8, and despite being powered by a massive 5.2 litre V10 engine with a seven-speed dual-clutch automatic and all-wheel drive (plus plenty of luxury features on the inside), the Huracan weighs in at a relatively svelte 1487kg empty.

Lotus Elise, Exige and Evora

Lotus has been using extruded aluminium structural members in its sports car range since the mid-1990s, when the first-generation Lotus Elise hit the road. Its diminutive size, small engine and alloy construction all helped it achieved a featherweight 725kg kerb mass – roughly half that of the average small sedan today.

Range Rover Sport

Range Rover managed to achieve a huge 39 percent weight saving when it transitioned the Range Rover Sport from a steel chassis to aluminium. It allowed the luxury off-roader to cleave half a tonne from its frame and make more room for suspension equipment and luxury gear.

Tesla Model S

Keeping weight low is of vital importance for electric cars, thanks to the tremendous mass of current battery technology. Any kilos shed from the chassis mean less battery capacity used up during acceleration, which results in extended range.

Tesla’s landmark Model S large luxury sedan is built around an aluminium “skateboard” made of extruded (forced out like a tube of toothpaste) and cast alloy components, which also carries the electric motor/s that powers it and the suspension it rides on. Aluminium is also used for the exterior body panels, further reducing mass.

COMMENTS