It’s easy, in 2017, to think of ourselves as a V8 nation.

V8s in local performance cars were once everywhere. Still are (but you’re shopping second-hand now). They won Bathurst. They created brands like HDT, HSV and FPV. There couldn’t be a single lover of home-grown performance cars that doesn’t love the V8.

However, here’s the rub. If you look back far enough, we’re also a six-cylinder tribe. Six bangers also won Bathurst – they provided Peter Brock with his first Mount Panorama victory. A six-pot (the EH S4) was the first Bathurst homologation special. The VL Commodore Turbo was the first local car to put ‘unleaded petrol’ and ‘performance’ into the same sentence.

Cars like the XR6T don’t come along every day. They couldn’t possibly, not when you talk to the people who were there and you begin to understand how it all happened. But, like most brilliant achievements, the XR6T was the brainchild not of a committee or industry think-tank, but of a handful of enthusiasts. And leading that very small handful was a bloke called Gordon Barfield.

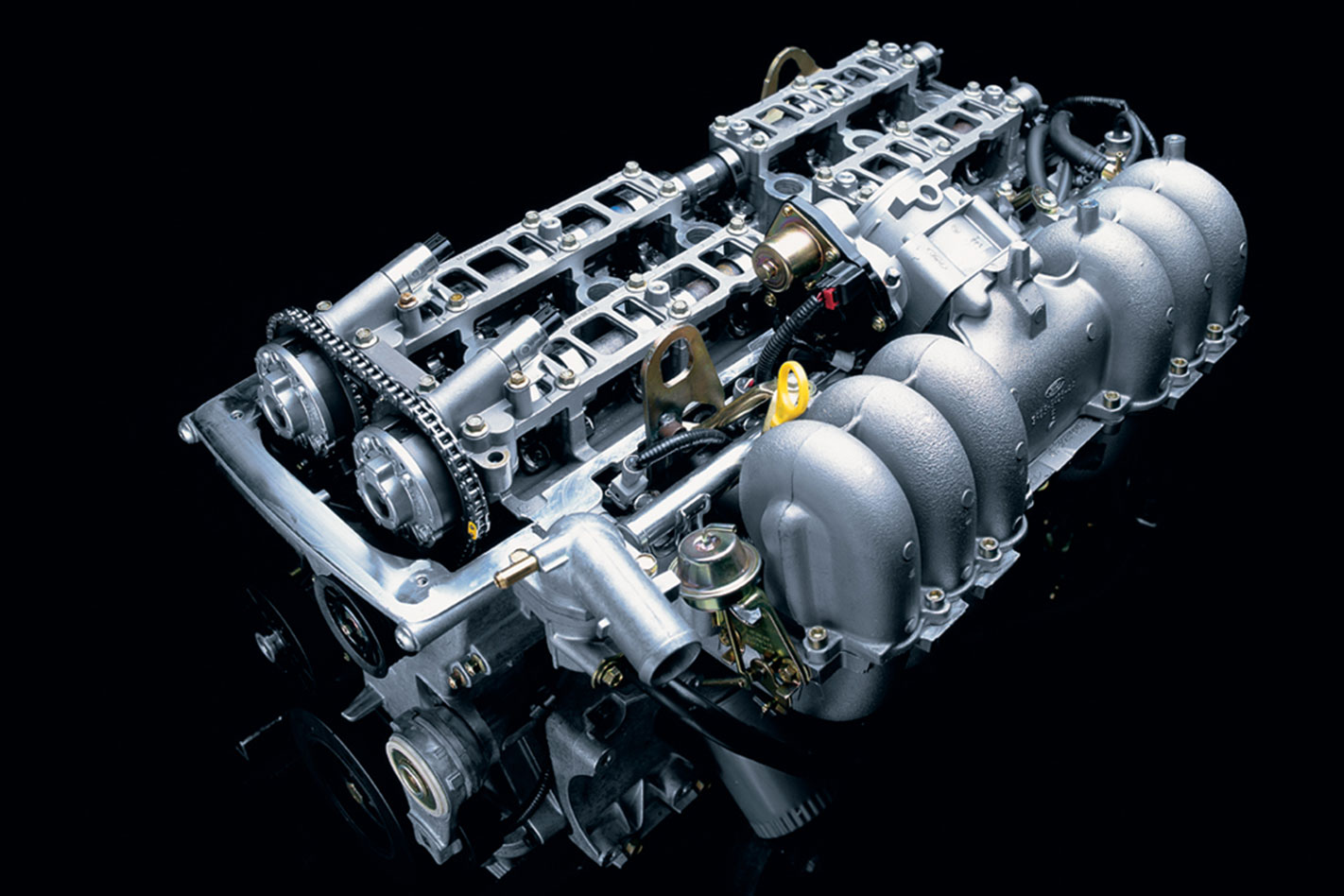

“Yes, the XR6 Turbo’ was my baby,” he admits, with no small hint of pride in his voice. “During the development of the four-valve six-cylinder, we (at Tickford) were saying, What are we going to do with this thing? How do we go forward? We could modify the engine and we might have got five kilowatts, but that wasn’t going to do it.”

As Tickford grew into FPV, the late, great Howard Marsden joined the planning team, and Howard’s instincts told him that a supercharged version of the Barra six would be a good thing. The problem was that the Barra project was already too far down the development track to be adapted to a supercharged application, and Barfield knew it.

“We couldn’t upset the existing architecture, the front-end drive (the belts and pulleys and such) so a supercharger was out. In fact, a supercharger would have put the development program back months. Howard had his eye on a Sprintex supercharger, but I said to him, ‘No, that isn’t going to work’.”

“Also, nobody (from the engineering department) was really making a grab for the real estate around the exhaust manifold – it’s too hot, obviously – so getting a turbocharger to fit wasn’t a huge problem. No, the problem was getting an intercooler to fit into the existing packaging. Luckily, our design principle was for a low-boost turbo on an engine that was already a high-torque unit, so we could get away with a smaller intercooler; one that fitted down low and out of the way.” The engineering, though, was the easy bit.

Ultimately, though, the XR6 Turbo project gained the support of Ford president at the time, Geoff Polites, and, crucially, engineering chief Trevor Worthington.

“I spoke to Trevor and he was really supportive. He could see the need for a model like this and also that there was nowhere else to go for a performance six.” Marketing was next and while plenty of punters could see everything that was right about the XR6T, that’s never enough at boardroom level. Eventually, though, the project was green-lighted, partly on the basis that with the low-boost nature of the thing, there was headroom for FPV to do more with the engine (and ultimately create the F6) as time passed and really build it into a performance dynasty. Which is exactly what happened (check the XR6T timeline). Let’s see how it all happened.

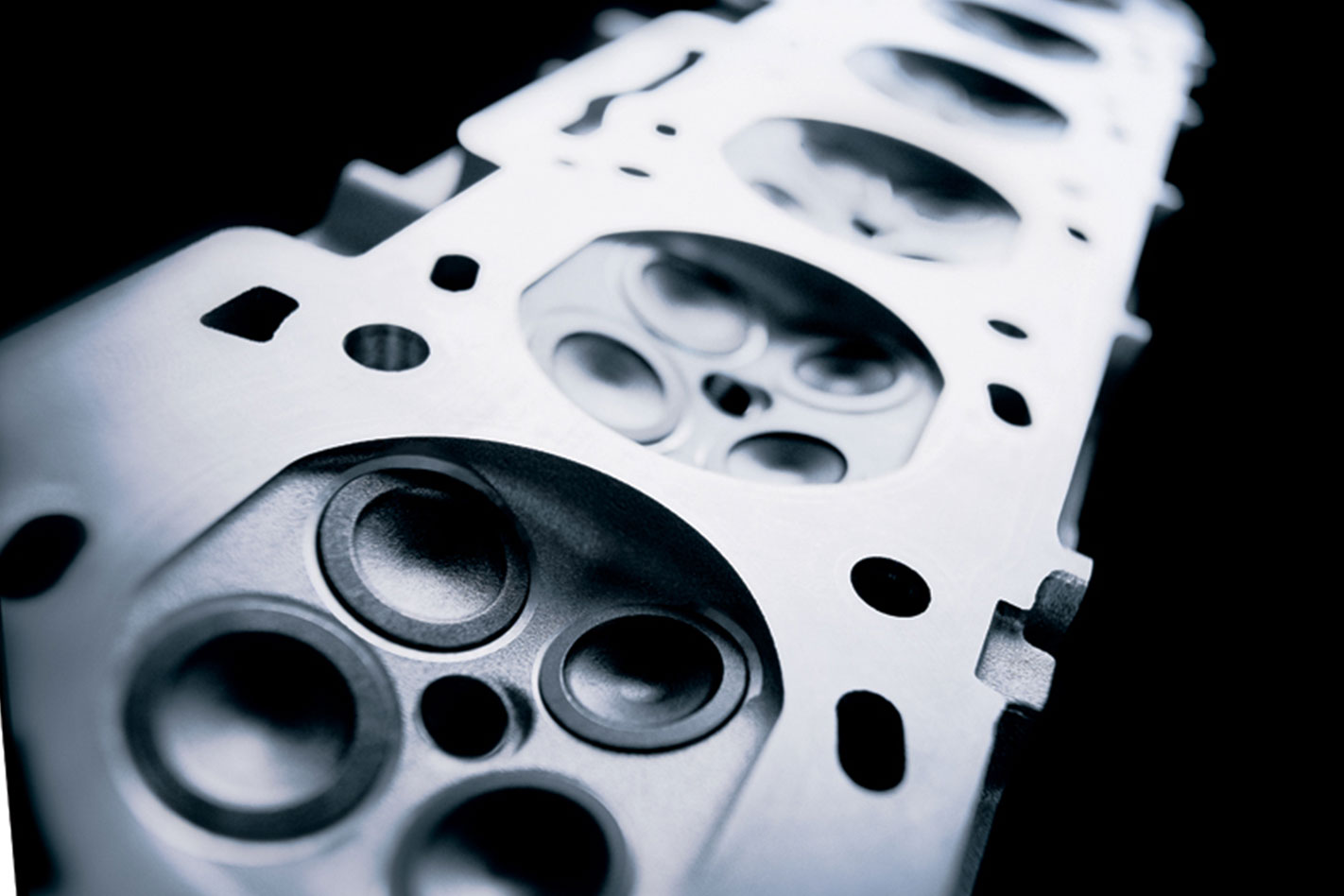

A large part of that rightness was an all-new DOHC, four-valve version of the Falcon 4.0-litre six. And by the time the Broady brains trust had got done with it, it was sporting a Garrett GT33/40R snail, bigger injectors and a lower, 8.7:1 compression ratio thanks to different pistons. Power leapt from the N/A Barra’s 182kW to 240kW and torque now maxxed out at 450Nm. And if you cross-reference those numbers with the Ford three and four-valve V8s offered at the same time, you’ll see that the blown Barra gave the three-valve a power (if not torque) hiding and the four-valve XR8 motor a big scare. Makes you wonder if Ford wasn’t pulling a few punches on the power output front to avoid any nasty comparisons, too.

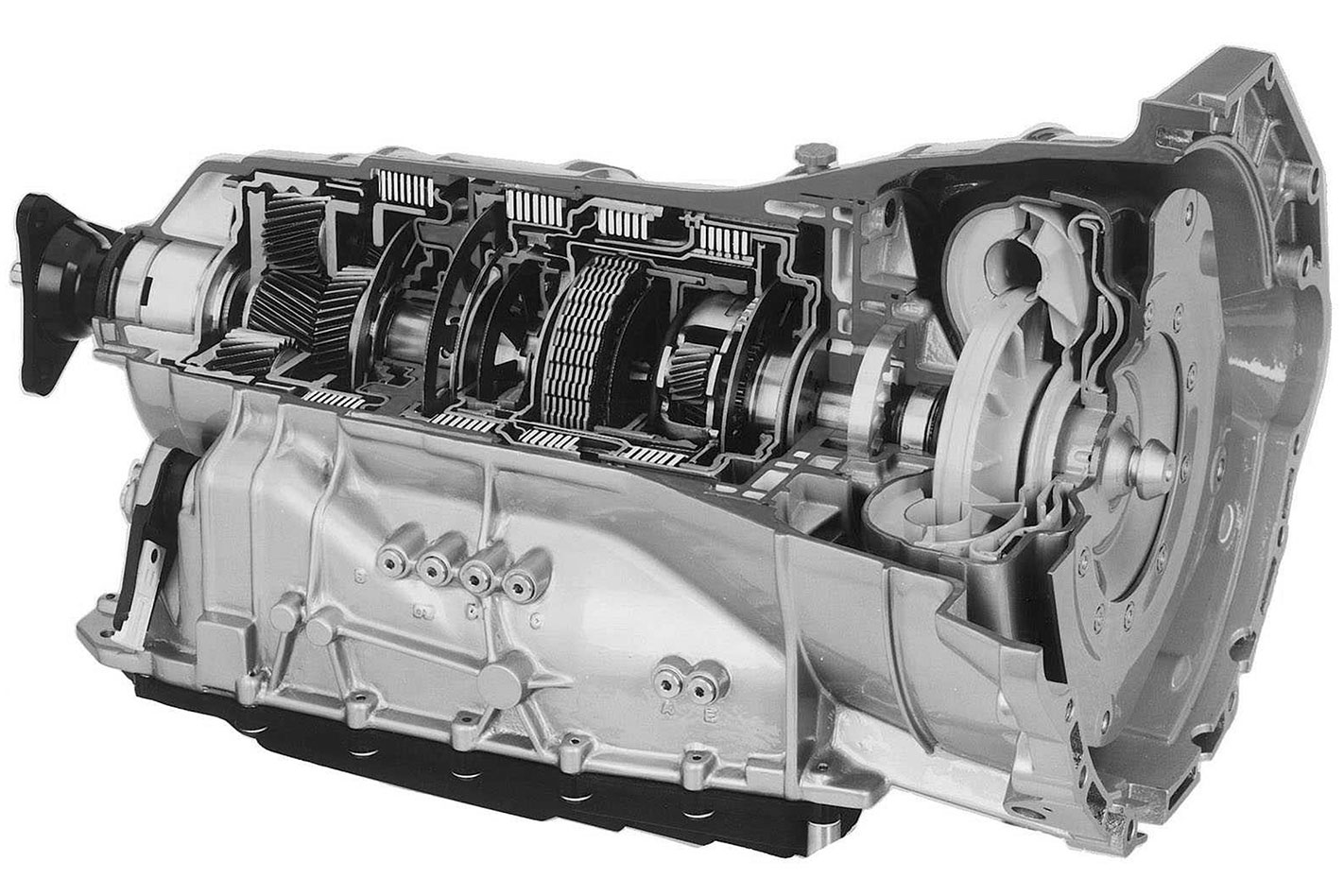

The auto was the nicer car, but either way, the XR6T had, from the moment showroom doors opened on the first morning, rewritten the book on six-pot poke.

From that point, the Turbo’s progress was one of refinement and improvement and the fact that it remained a strong seller right up until Ford Oz pulled the plug on local manufacturing back in late 2016, proves just what a star it was. The first of those improvements came with the BA Series II in 2004 when the XR6T got a six-speed manual to replace the old T5, but it wasn’t until the BF model in 2005 that the four-speed auto was replaced by a new six-speed ZF unit. Power also got a kick up the bum at this point to 245kW and torque was now 480Nm. But the improved gearing meant that even though performance was up, so was fuel economy. Win-win.

If that was the bottom end the car had always been crying out for, in 2008 with the launch of the FG Falcon, the XR6T also got the snail it had been waiting for. While the early design used a big turbo to keep boost happening at high revs, that also made it a bit laggy. The smaller unit fitted to the FG version reduced that lag while better engine management kept it boosting longer. Power was now 270kW and torque was a much beefier 533Nm.

As a thank you note to those of us who had fallen in love with the blown Barra all those years ago, Ford used the very last Falcon, the FG X, to present us with the best XR6T ever. Dubbed the Sprint (there was an XR8 Sprint, too) the final iteration of the whole concept combined the best bits for a whopping 325kW and 576Nm.

Talk about saving the best till last.

Key Points to Look for When Buying a Barra

Right, about now, you’re probably thinking: yep, I need me an XR6 Turbo. Catch is, of course, that you’ll be buying a car that somebody else has thrashed before you. That said, they’re pretty damn tough, and there’s a wealth of knowledge out there that can predict what’s going to go bang.

All XR6Ts are hard on their diff bushes, too, so check them for play and check the service book. Ideally, the previous head-banger has changed the oil and filter at 10,000km intervals, not the 15,000 ones listed in the handbook. Sludgy oil can eventually block the oil feed to the turbocharger which then starves and fails.

Early XR6Ts experienced the odd piston failure, but it was rare and running changes fixed it. Valve springs were also a bit underdone in those early cars and intake gaskets could fail. A lot of cars were left with no go when the cam-angle sensor wire in behind the cylinder head got cooked over time, became brittle and snapped. It’s a common fault. Stock brakes on the XR6T were seriously underdone and would warp on a warm day. Aftermarket replacements are needed.

Centre-bearings in the tail-shaft were always a bit of a problem, too, but the fusion-welded tail-shaft that came in with the FG model is also a bit prone to twisting. A conventionally welded replacement tail-shaft from an earlier model is the go. The FG’s turbo pipe was also notoriously thin in places (due to core-shift in the casting process). The world is full of viable replacements.