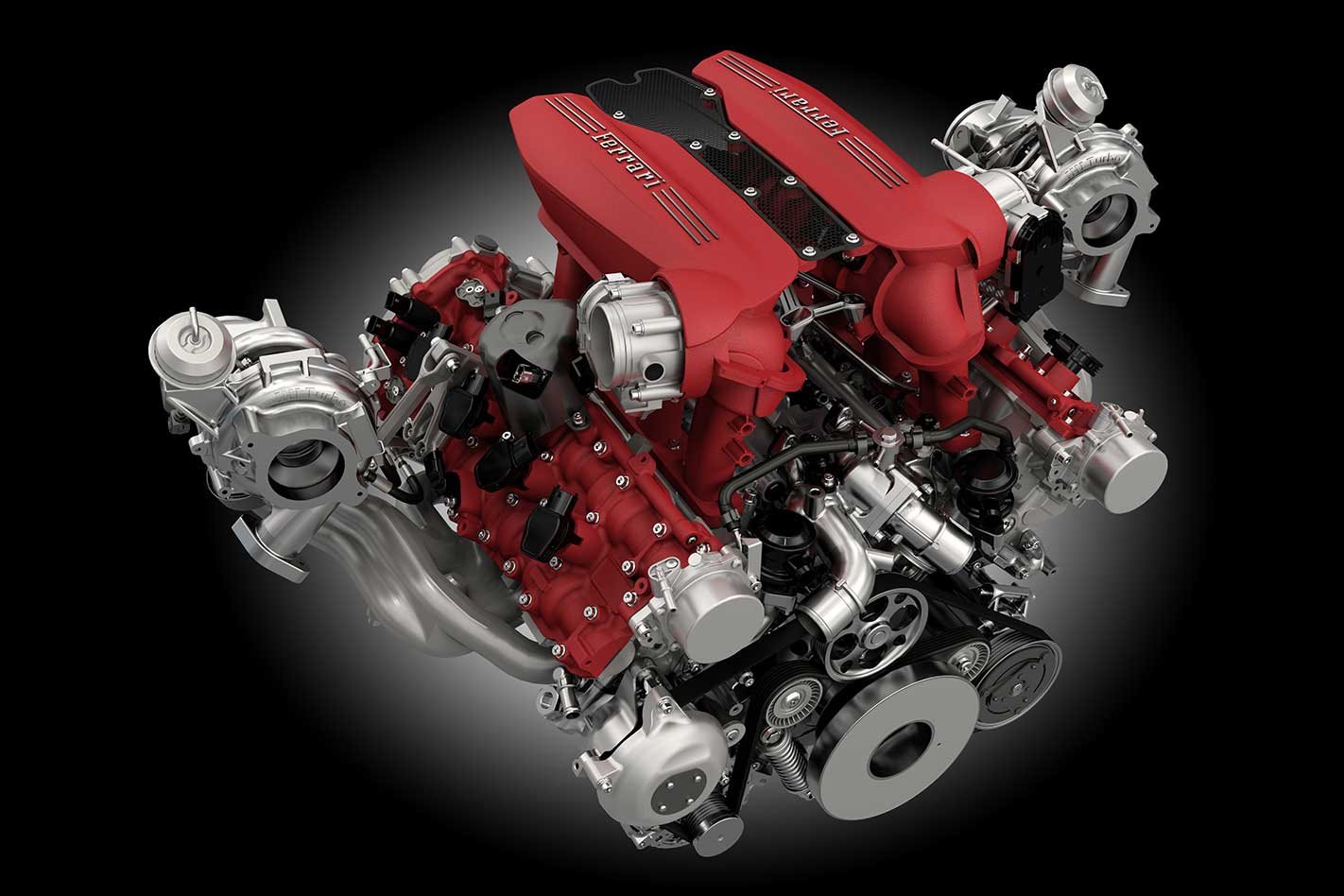

Ferrari is so determined to stop turbochargers from sucking the drama out of its venerable engines that it’s devised plans to basically reinvent the technology. The Italian outfit recently logged a patent in Europe detailing a unique turbo system that, if executed properly – on engines such as those in the 488, seen right – will blow away convention and the competition.

However, before we dive into the juicy details behind Ferrari’s uninspiringly titled ‘Method To Control An Electrically-Operated Turbocharger In A Supercharged Internal Combustion Engine’ document, let’s cover the basics.

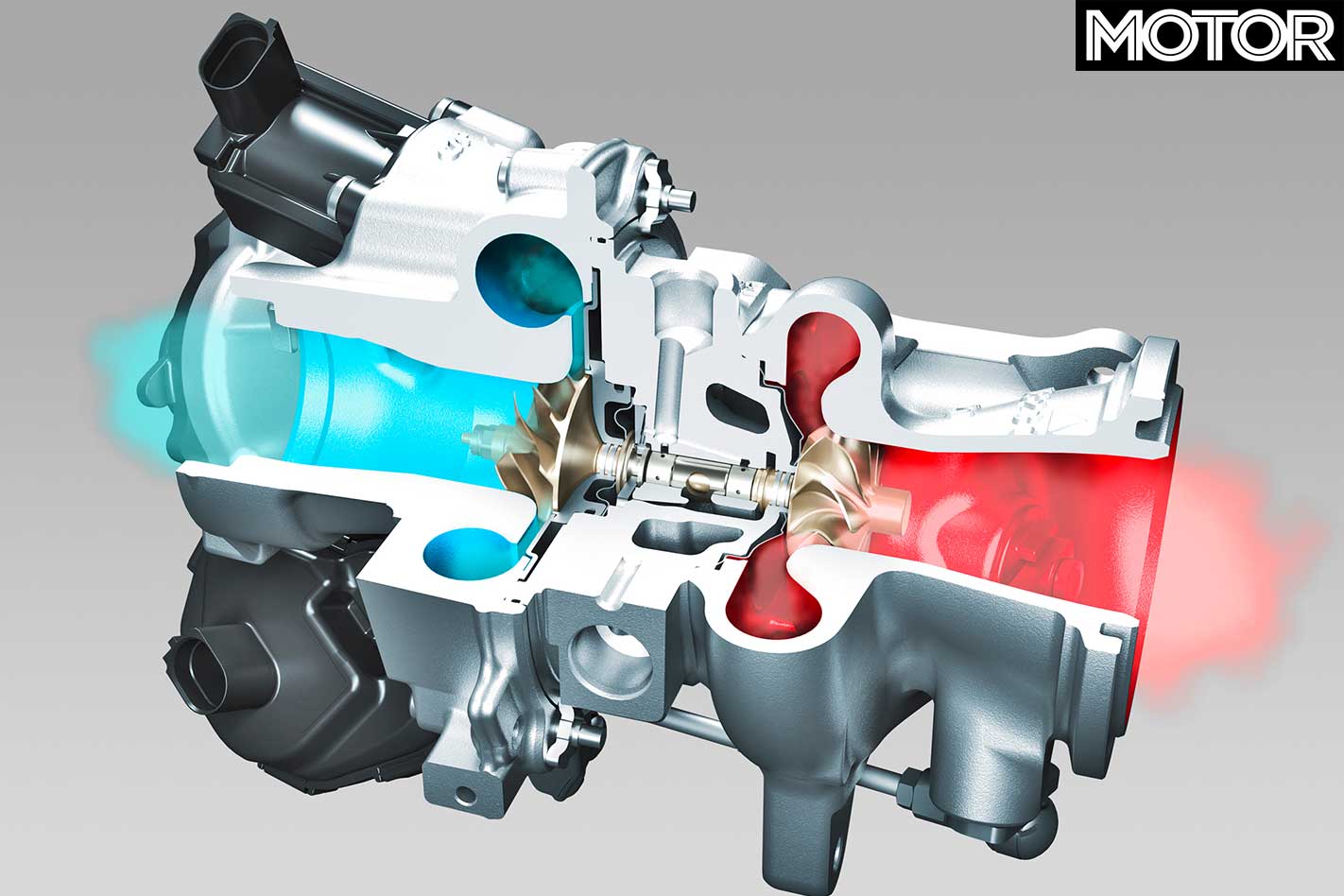

Living in a snail-like housing, this is connected to another fan, in another snail-like housing very nearby, by way of a shaft. This other fan, the compressor, pumps air into the engine. More air, more fuel, bigger bang, more power.

Traditionally, there are costs. Response is one, efficiency another, then there’s making it all fit in the engine bay. Yet perhaps most important to a company like Ferrari, which prides itself on the cry of its atmospheric engines, is sound. This, and throttle response, has kept its engineers up at night.

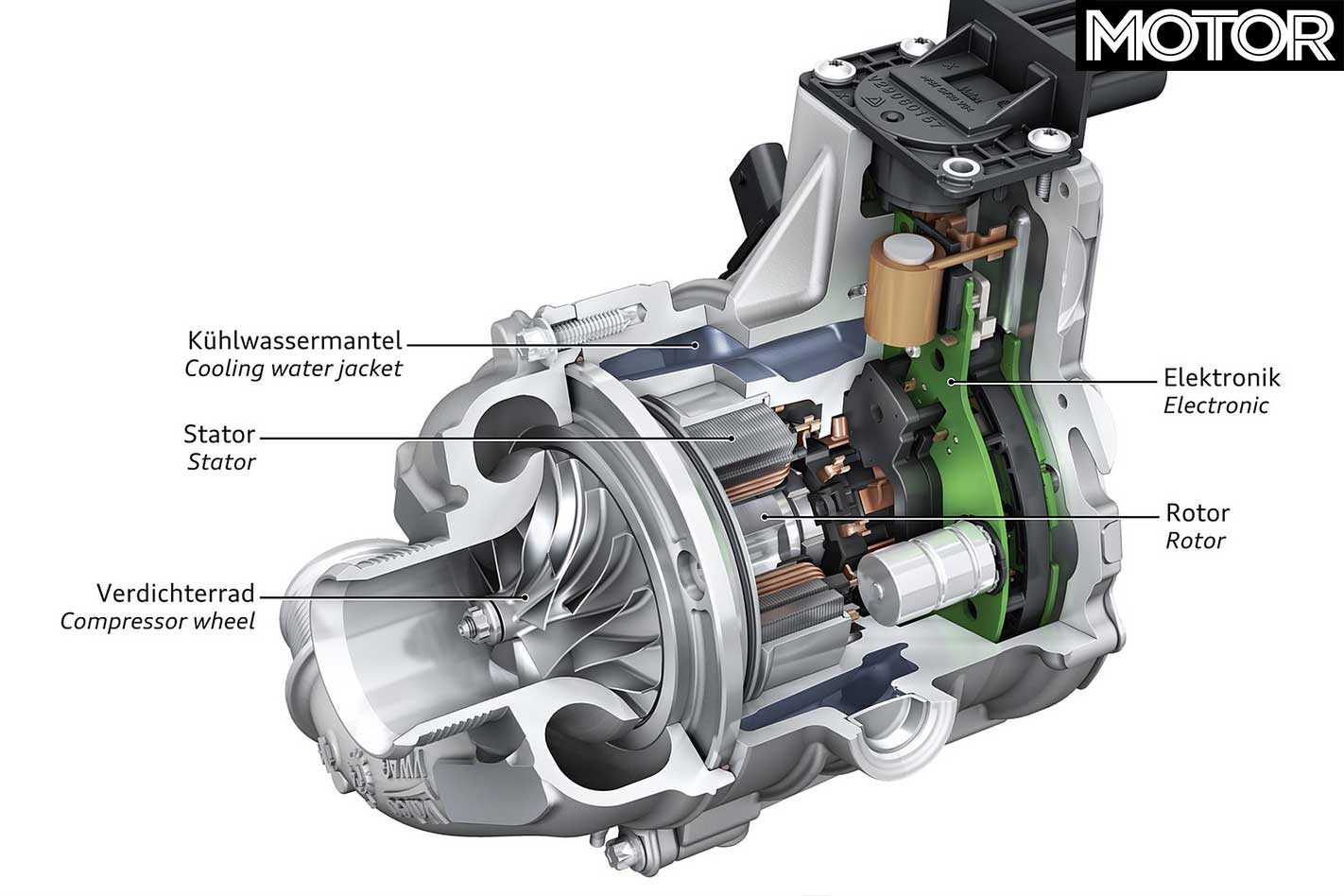

And so, in what could be one of the happiest petrol-electric marriages thus far, Ferrari has used electricity to split the turbocharger. In this patent, Ferrari ditches the turbine-compressor shaft and divorces the two parts completely. Instead, the compressor is now driven by an electric motor, allowing it to reach a desired rpm (and boost figure) as fast as that motor can deliver it (almost instantly).

There’s still a turbine but it now spins a generator. This generator charges a battery, which supplies juice back to the compressor’s motor.

So smart yet so simple, huh? This also allows both components to be designed without any compromises needed to accommodate the other’s goals (boost, flow, efficiency) but the real advantage is the turbine’s generator can charge the battery pack even when boost isn’t needed.

On top of that, if there’s enough electrical charge (which is always the case in higher rpms, according to Ferrari), the generator’s resistance can be eased to quicken exhaust flow and “increase the intensity of acoustic emission”. Which makes us want to get up and dance about in a jig.

It’s all very clever. And electric turbocharging isn’t all that’s similar to Ferrari’s F1 tech here, as the patent outlines an extra electric motor nestled in the car’s drivetrain. It’s hooked to the same battery as the turbine and can either assist charging it, or drain it to deliver a power hit directly to the wheels, F1 KERS-style. Expect big power from such applications.

In doing this, Ferrari has envisioned turbocharging with very few downsides and given us a glimpse into what might transpire in the following years. While there’s no way of telling how far this technology has been taken within its engineering wings, it’s a blueprint that shows how Ferrari might deliver on the promise of ultimate performance and its commitment to more hybrid vehicles.

Importantly, it reveals what’s possible for fast cars in a turbocharged, electrified world. Bring it on.

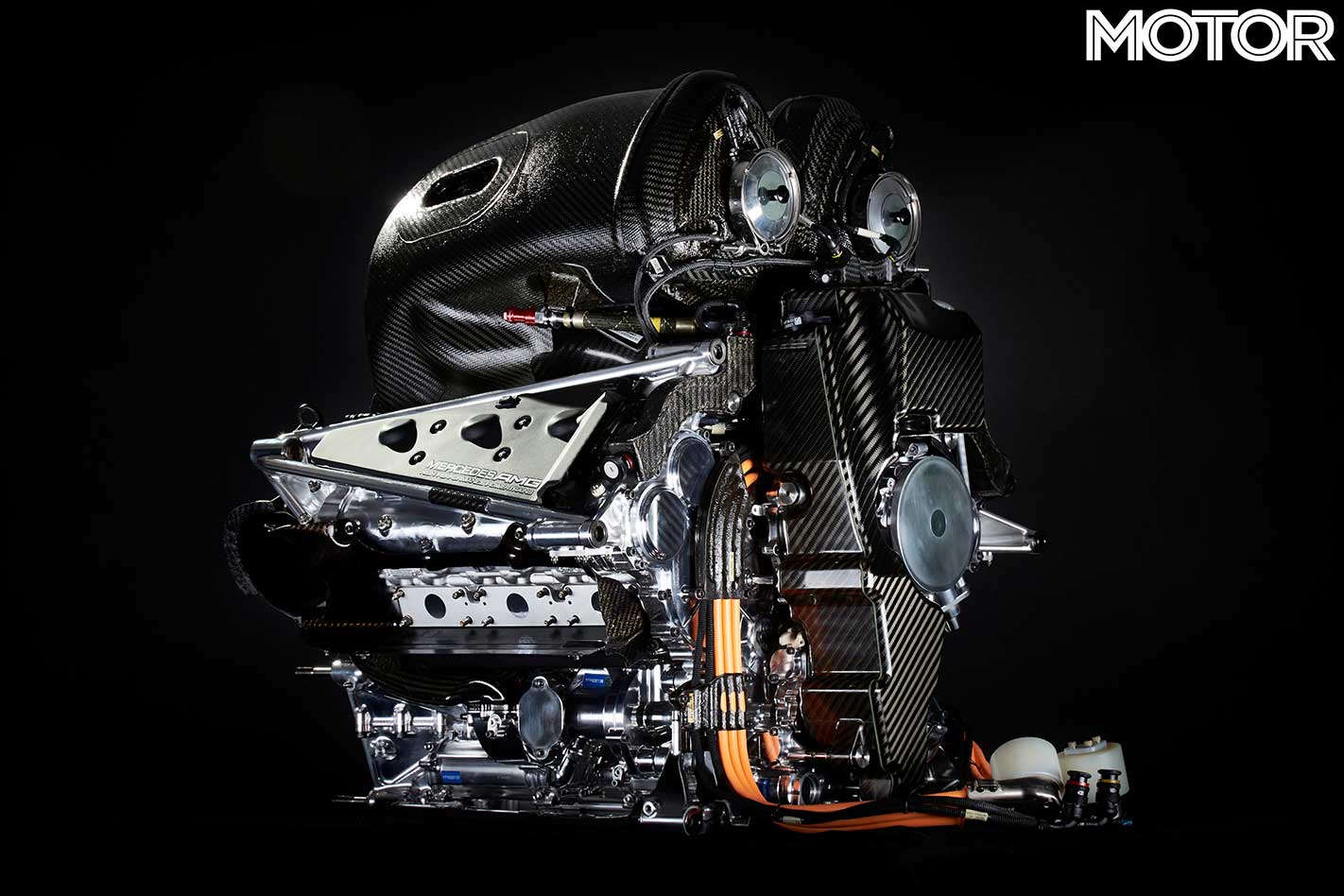

A Championship Winning Idea

Mercedes-AMG has also experimented with splitting the turbocharger, but in its Formula One cars – and to devastating effect. With Formula One’s hybrid turbo era forcing an MGU-H on teams, Mercedes-AMG saw the opportunity to split the turbine and compressor on either end of the 1.6-litre V6 in the W06 racer. The shaft remained and ran in between the engine’s valley and through its generator/motor.

By doing so, Mercedes gained crucial advantages, with a cooler compressor gifting the team more reliability and power. It also shrunk the required cooling gear, which thinned the car’s bodywork and reduced drag.

Initial press shots of Mercedes-AMG F1’s power units actually featured a completely different turbocharger and MGU-H design to disguise its idea. The technology, though, has become much more public after Mercedes-AMG announced its road-going Project One hypercar will launch with a de-tuned version of its F1 power unit.

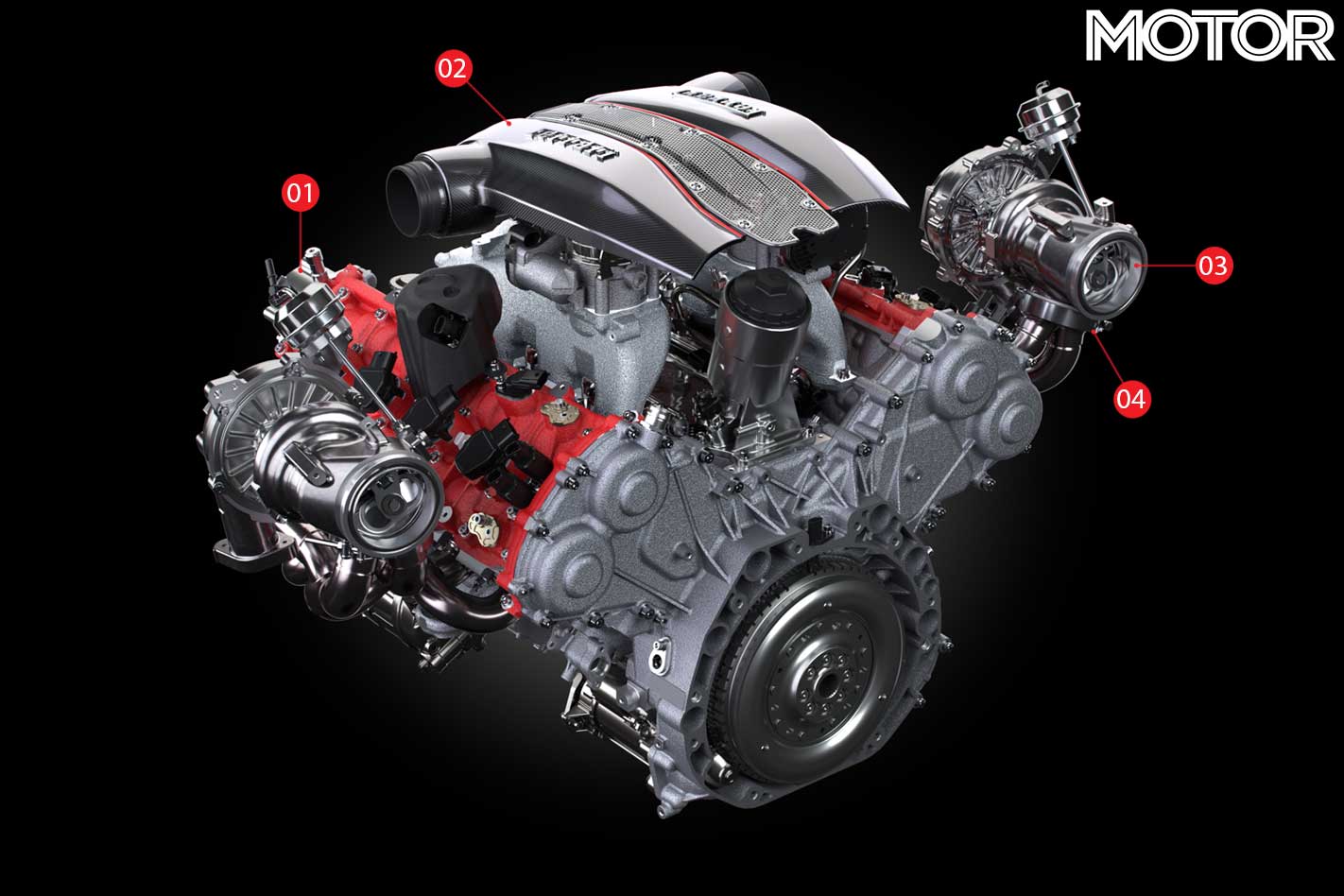

How Ferrari’s split electric-turbocharger will change the game

01 – IT WILL SOUND BETTER A microphone in the cabin near your ear will help determine how much extra growl the turbine needs to make, says Ferrari. Since it’s fully manipulated by the software controlling the turbine and generator, it also can be tuned with different maps for each drive mode.

02 – IT WILL PACKAGE BETTER Separating the turbine and compressor creates new packaging options. The compressor can now be isolated from exhaust components, shrinking cooling needs, and radiator sizes, and can be placed upstream closer to intake manifolds.

03 – ECONOMY GAINS The turbine can now capitalise on the extra space by being situated away from heat-sensitive parts. Exhaust manifolds can be lengthened for efficiency, which reduces back pressure, enabling leaner fuel ratios and improved economy.

04 – SHOCKING GENIUS It’s an inspired idea that melds the concepts of electric supercharging with the MGU-H tech (Motor Generation Unit Heat) that Ferrari uses in F1. Fabrizio Favaretto, head of hybrid and rear-engine systems, is credited as the inventor.