Ford has been developing and selling V8 engines for road cars since 1932, when it introduced the Flathead in its Model 18.

The Flathead would go on to become a performance leader for decades, and is surely among the pantheon of Great V8s. But we aren’t here to talk about the mighty Flathead V8, instead focusing on a Blue Oval engine dynasty that was hatched in the 1980s, and for almost three decades has powered a plethora of FoMoCo’s passenger and performance cars – it is of course the Modular family of engines.

In the early 1980s, Donald Peterson was the COO of Ford, and he had a desire to shake up the boxy, drab design that had dominated the company’s vehicles for several years. He challenged then vice-president of design, Jack Telnack, and his staff to come up with a new design language that the company could take pride in – resulting in sleeker, more aerodynamic cars gracing Ford showrooms.

This success helped in part to elevate Peterson to CEO, and by the mid-1980s he wanted the same revolution that had swept through the design department to occur with Ford’s decade-old V8 architecture.

Jim Clarke was chosen to lead the project, with a simple yet challenging brief set by Peterson. The new V8 design needed to surpass the brand’s current V8s in every meaningful way – power, efficiency, emissions, performance, and smoothness of operation

Clarke and his engineers studied bent-eights from both Europe and Japan, and decided on a plan that would result in a V8 that was technologically advanced and power-dense, yet dependable and reliable enough that it wouldn’t need a major service until after 160,000km.

A 90-degree vee angle was chosen, and an almost 1:1 bore-to-stroke ratio for improved NVH characteristics. But the most important decision, which would result in the new design’s longevity, was to have a bore spacing, deck height, and bell housing bolt pattern that could remain unchanged, and still spawn an entire family of engines. Ford would group these V8s under its Modular Family of engines.

The link between Ford’s Modular engines is the 100mm bore spacing that allowed for multiple variations, with single- or dual-overhead camshaft configurations, different displacements and block materials, and even different cylinder counts. A V10 was spawned from the family, while a V6 was evaluated but never received a green-light for production.

The wide array of possibilities spurred Ford on to develop a new modular tooling system for the engines’ production, so they could all be built efficiently within the same factory.

By 1987 Ford was all-in, having invested US$4 billion in the architecture’s design, and retooling the Romeo, Michigan tractor plant to build the engines.

The first production V8 from the Modular family was a 4.6-litre SOHC unit for the 1991 Lincoln Town Car. Despite being smaller than the 5.0-litre pushrod it replaced, the new engine was more powerful, more fuel efficient, was 9kg lighter, and could propel the new model to 60mph (97km/h) 1.5 seconds quicker.

Jim Clarke’s new V8 family was a roaring success, and the 4.6-litre V8 would proliferate much of Ford’s range for the next 20 years. As a new decade dawned in 2010, so did a major update for the Modular family, in the form of the 5.0-litre Coyote design.

Built for the 2011 Ford Mustang GT, the Coyote was built as the Blue Oval wanted something to take on General Motor’s 6.2-litre LS3 V8, and Chrysler’s 6.4-litre Apache Hemi.

Continuing the Modular lineage, the Coyote shared the same 100mm bore spacing as the 4.6-litre, allowing it to be built with the same tooling from the late ‘80s. This meant displacement could only be increased nominally, stretching to 5.0-litres by increasing the bore and stroke to 92.2 mm and 92.7mm respectively. The Coyote was smaller than its competitors, but remained competitive in terms of power.

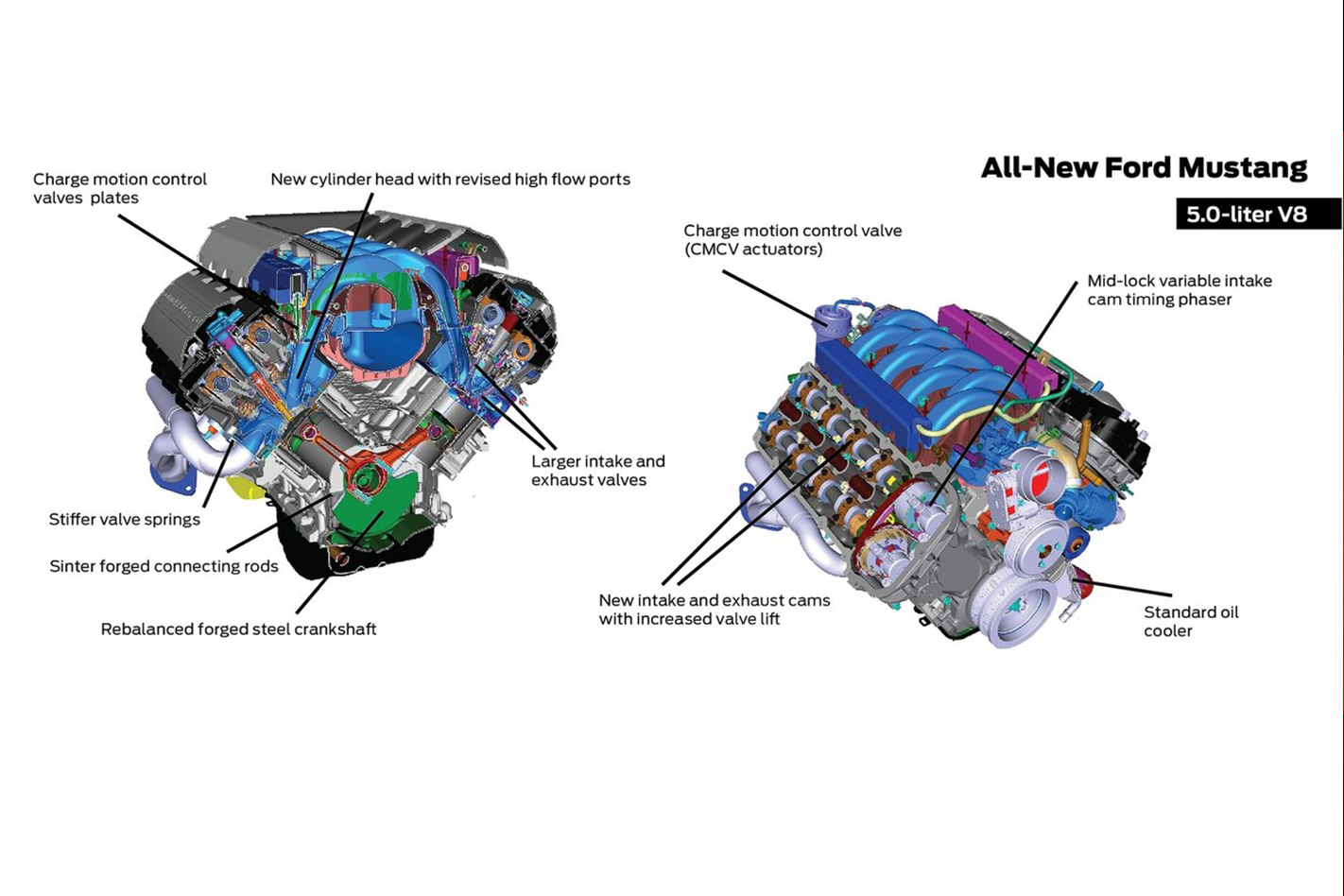

A raft of ‘Gen 3’ updates were introduced in 2018, resulting in the engine Australians can now drive in the current-gen Mustang GT. This is the zenith for mainstream naturally-aspirated V8s in the Modular family, with a raft of advanced technology resulting in 343kW and 569Nm claimed power outputs.

However, that’s not where things end, with the Ford Performance division turning the heat up with three special versions, Voodoo, Predator, and Miami.

Voodoo is the atmo screamer fitted to the Shelby GT350 and 350R, with a flat-plane crank, larger bore and stroke, and increased compression ratio resulting in 392kW at 7500rpm, and 582Nm at 4750rpm, with a 8250rpm redline.

Predator is yet to hit production, but will appear in the 2020 Mustang Shelby GT500. The 5.2-litre supercharged V8 is claimed to produce 570kW and 847Nm – the most powerful Blue Oval product yet.

Australians will be most familiar with the Miami, which was developed by the Ford Performance Vehicles (FPV) branch locally, for our hottest Falcon sedans and utes. The supercharged 5.0-litre was sold in various tunes, but the most extreme came from the team at Premcar, which was formed following the end of local production. The Victorian-based team turned up the heat for the Miami until it cranked out 483kW/753Nm, all while meeting OEM-standard durability tests.

Outside of the Ford family, the Modular V8 has been used by Koenigsegg to dethrone the McLaren F1 as the world’s fastest production car in 2005. The CCR was powered by a Rotrex-supercharged 4.6-litre producing 601kW to a speed of 388km/h, and was only bested by the herculean Bugatti Veyron.

To illustrate just how far the Modular V8 design can be pushed, Modular Motorsports Racing built a drag racing engine based on the Coyote, with factory cylinder head castings, valves, and lifters, but a billet reproduction of the block. The result was a 5.8 second pass over the quarter mile, with a 412km/h trap speed.

Not bad for a design dating back to the ‘80s.

Manufacturer | Ford |

Production | 1991-present |

Configuration | 90u00b0 V8 |

Bore x Stroke | 90.2-94mm x 90-105.8mm |

Displacement | 4601-5808cc |

Valvetrain | OHC |

Power | 142-570kW |

Torque | 466-847Nmu200bu200b |

Click here to read more Wheels features on Great V8s .