IF YOU intend to do any extended off-road touring it makes sense to utilise a dual-battery setup to power 12V equipment and protect the primary battery. Historically, vehicles commonly used a fixed voltage alternator to replenish the starter battery losses from cranking duties during engine start-up, before supplying power to accessories and electrical systems with the engine running.

Given the relatively high voltage output from this type of alternator, it was able to provide a sufficient charge for a second battery of similar construction that was wired in parallel to the starting battery. A manual or automated solenoid control would separate and protect the starter battery when the engine wasn’t running. This simple system effectively addressed most of our 12V needs.

Seeking lower emissions and greater fuel economy, modern electronics have altered the fundamental operation of many systems within the modern four-wheel drive. The vehicle’s smart alternator can vary its output to reduce the load on the engine across a range of operating conditions, but manufacturers design their smart alternator to look after the starting battery and the vehicle’s own electrical systems power needs, not an auxiliary battery.

Depending on the type of auxiliary battery fitted, the alternator’s variable output may fail to fully charge the battery. From the first time you start to drain the auxiliary battery a destructive cycle begins, significantly reducing the battery’s lifespan and operational capacity.

Repeatedly reaching deep into the battery’s reserves to deliver power to hungry 12V devices increases the risk of complete battery failure, as it is only ever partially recharged due to the normal function of the smart alternator.

If you think you never seem to have a fully functioning dual-battery system in your modern fourbie, you’re not alone. Buying bits and pieces and bolting them together to create a dual-battery system isn’t hard; the challenge is correctly matching the size and capacity with the functionality of each piece of equipment, so they work seamlessly with a smart alternator to provide reliable and effective power management. Fortunately, the aftermarket is solving the problem with new-gen management solutions.

CTEK’s longevity in the industry ensures it understands the demands placed on a dual-battery system and how it must integrate into the complex electronics of a modern 4x4. From complex caravans to rugged 4x4 tourers, CTEK’s new 140A Off-Road Power Charging system has been specifically designed to maintain and optimise the capability of any dual-battery system.

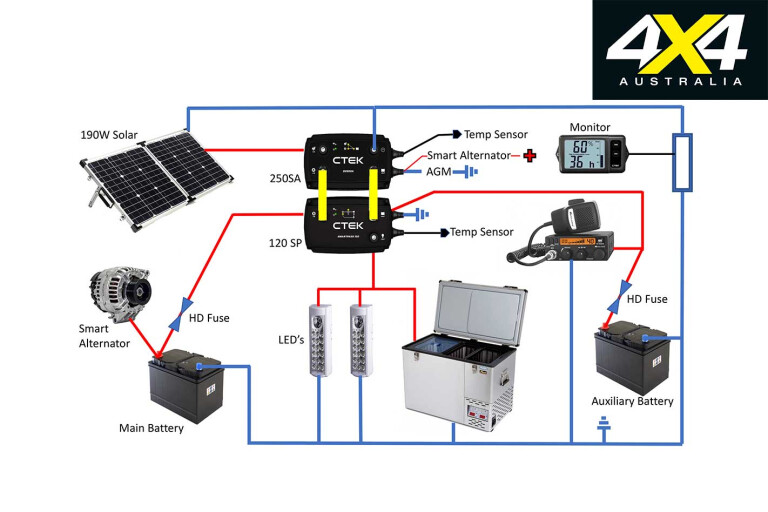

The kit contains a D250SA DC-to-DC 20amp five-stage battery charger to ensure a consistent and correct charge for your auxiliary battery. A SmartPass 120 Manager is included to control the charge and power flow to the 12V devices connected to the dual-battery system, with redundancy for assisted cranking in an emergency. The units are rated at IP65 for splash and dustproof standards, and there’s a remote-mountable monitor with a large, clear screen to provide battery status information at a glance.

Power is sent from the alternator to the 120 and then across to the battery charger via the connector plate, allowing the charger to combine solar input (via its dedicated solar terminal) and output to the auxiliary battery. The unit will accept solar input from 50 to 300W panels, with control provided by the internal MPPT solar regulator to maximise input.

Non-critical system accessories – fridges, lights and chargers – can be switched and powered directly from the alternator when the engine is running via the dedicated accessory terminal on the SmartPass 120. This gives the option to connect critical systems such as communications to the auxiliary battery.

Installation is within the capability of an experienced tinkerer. Joining the two units via the supplied voltage bus connector plates eliminates additional cabling, and the units form an integrated 140amp management system capable of rapidly charging an auxiliary battery; with intelligent control for balancing multiple inputs.

As with most battery management systems, position the units as close as possible to the auxiliary battery but away from excessive heat. Remember, the further the auxiliary battery is away from the starter battery the heavier the cabling needs to be to deal with the amperage. Check the reference guide in the user manual for suggested dimensions for cabling and fusible link capacities.

By following a detailed diagram, hooking up the cabling is straightforward, with easy-mount terminals located on the front of each unit. Remember to torque the terminal bolts as instructed so you don’t end up with a loose connection after a few kilometres of corrugations, and always ensure there’s a solid earth connection – a large percentage of issues are traced back to a bad earth connection.

The charger has one small red wire and one black wire. The red wire connects to an ignition feed if a smart alternator is used, and the black wire is connected to ground to increase the voltage output from 14.4 to 14.7V for an AGM battery.

Disappointingly, the system doesn’t accommodate LiFePO4 batteries, with CTEK offering a separate charger to accommodate lithium batteries.

The D250SA’s temperature sensor is easy to mount on top of the auxiliary battery and close to the positive terminal, allowing the system to monitor battery temperature and adjust charging rates accordingly to optimise efficiency in both cold and hot conditions.

The D250SA also includes a battery separator, negating the need for a voltage sensitive relay to protect the starting battery. It has the ability to run simultaneous inputs from both alternator and solar panels, with a trickle charge function to top-up the starter battery once the auxiliary battery is fully charged via the five-stage charging profile (desulphurisation, bulk charge, absorption, float and a pulse, to maintain the auxiliary batter at 95 to 100 per cent capacity).

The SmartPass 120 system, which can only be used in conjunction with the D250SA, ups the ante by accepting an input of up to 120amp, with a burst of 350amp for ten seconds when engaging the start assistance function. This enables access to power from the auxiliary battery, to crank the engine if the starter battery is flat.

There’s also a battery guard control to ensure any critical systems have power whilst avoiding the total discharge of the auxiliary battery. The clever design of this system enables equipment to source power directly from the alternator when the engine is running, allowing the system to maximise charging input to the auxiliary battery and reduce charging times.

Both the D250SA and SmartPass 120 have built-in LEDs to confirm normal operation or indicate fault. Simply looking at the lights displayed and referencing it with the user manual will provide an insight into any problems. The remote screen is large and clear with a crisp digital readout. At night the screen has peripheral blue lighting shining across the readout, but backlighting the screen would be better.

There are various displays that can be selected: ‘Time to go’ shows the battery capacity as a percentage, plus an estimate in time left to fully discharge the battery; alternatively, the Voltage and Current screens show current battery voltage and amperage.

The unit is 70mm high, 100mm wide and needs approximately 250mm for working length, so the components aren’t exactly compact; join them together using the supplied connecting plates and you’ve compounded the issue. The system best suits those with a ute (with a canopy), or a caravan/camper with a large storage boot. It will also work if you can utilise an existing mounting panel, or have room to mount one inside your vehicle or beneath the seat.

Owners with limited real estate will find this system presents installation challenges. Chat with your favourite 4x4 shop to see if they’ve fitted the system to your vehicle model before; or, if you’re happy to spend the time and you’re handy with tools, you could always make your own custom mounting box.

The 140A Off-Road Power Charging system provides the capability to monitor battery temperature and adjust the output; it can simultaneously accept solar and alternator inputs; it can enable intelligent prioritisation for powering accessories and reducing charging times; and it has the capacity to accommodate battery banks up to 800amp/h.

It’s clear the CTEK system can meet the heavy demands and high expectations we have for dual-battery capacity and performance, so if you have sufficient space to mount the CTEK 140A Off Road Power system then it’s is definitely worth your consideration.

RATED

Available from: www.ctek.com

RRP: $1299

We Say: Quick charging; reliable; takes up space.

COMMENTS