Armed with a bit of knowledge and a fair dose of common sense, extracting a vehicle from a stuck situation using a vehicle-mounted electric winch is often straightforward, but as with all things when driving off-road, complications are a part of the game.

Sure, there are plenty of scenarios where a straight-ahead, single-line winch pull will get you out of strife, but throw in some obstacles and pretty soon your winch could run out of puff, or the situation might mean you need to winch at an angle rather than straight ahead.

The further you drive off road, the greater the chance you’ll need to get a little creative with vehicle recoveries from time to time, so in this ‘How To’ instalment we’re going to look at a couple of advanced winching techniques where you’ll need to employ snatch blocks or winch rings to perform a vehicle recovery, as well as winch extension ropes.

Required gear

As with any winch recovery, you will need a winch on your vehicle equipped with steel cable or synthetic rope. You will also need a solid anchor point (often a suitable tree), a winch controller, sturdy gloves, a recovery damper, a tree-trunk protector and a rated soft shackle or bow shackle.

For a more complex double-line pull, you will also need a snatch block or a winch ring, a winch extension strap or winch extension rope, an additional rated soft shackle or bow shackle, and an additional recovery damper.

For the sake of simplicity, from now on we’ll refer to the use of winch ropes and winch rings rather than winch cables and snatch blocks, but these items fulfil the same functions, so if your vehicle is equipped with steel cable and you have snatch blocks in the recovery kit, the techniques described here are still relevant.

We’ll also refer to the use of winch extension ropes instead of winch extension straps, as the former is more versatile in that it can be fed through a winch ring if necessary.

All recovery equipment should be rated to suit the weight of the vehicle being recovered, and it should be clearly stamped or labelled. You will also need to have rated recovery points affixed to your vehicle, which are not to be confused with shipping tie-down points that are only to be used when vehicles are transported.

Another thing to note is that winch extension ropes are similar in appearance to kinetic recovery ropes, and the two are not interchangeable. Winch extension ropes do not stretch like kinetic recovery ropes, so they should never be used for snatch recoveries. If in doubt, always check the label to make sure you are using the right equipment for the job at hand.

In addition to the equipment outlined above, some other handy gear to have when performing a winch recovery includes a shovel, a machete and a handheld UHF radio.

The shovel can be used to clear away mud, rocks, sand and other debris around the vehicle before commencing winching, the machete can be used to clear away bushes, branches and scrub so you’re winch rope doesn’t foul on anything, and the handheld UHF can be used for communication between the driver and the person operating the recovery equipment.

Remember, whenever you perform a vehicle recovery, make sure that all non-essential bystanders are well clear of the operation. The only people who should be involved in any recovery operation are those driving the vehicle(s) and those operating the recovery equipment.

Double-line pull

The first advanced winching technique we’re going to look at is the double-line pull, which you usually employ when the vehicle that needs recovery is really stuck, or when you are travelling on your own and you want to minimise the load on your winch.

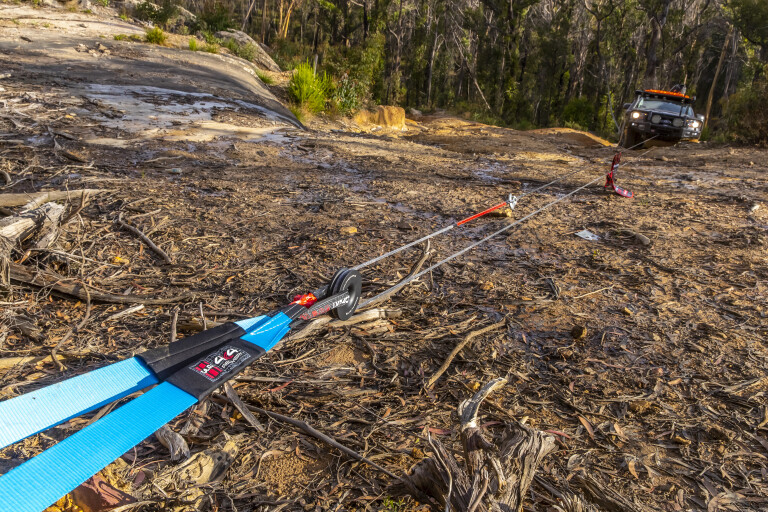

A double-line pull is where you run your winch rope up to an anchor point, through a winch ring and back to a recovery point on the front of your vehicle. Other than some minor energy loss through friction, a double-line pull doubles the pulling power of your winch by halving the load on it, so ideal if stuck fast in gooey mud or you need to winch up and over an obstacle. Also, as the winch will not have to work as hard when you employ a double-line pull, it will reduce the load on the vehicle’s battery.

Setting up a double-line pull is relatively straightforward if there’s a nearby anchor point such as a sturdy tree; remember, the winch rope will need to be long enough to run up to the anchor point and back to the vehicle. If the anchor point is not close enough, you will need to use a winch extension rope.

The first thing to grab out of the recovery kit is a pair of sturdy gloves. Gloves will protect your hands from frayed wire on winch cables and from friction burns when running synthetic ropes. Next, plug in the winch controller and if you are travelling solo, run it back through the driver’s window so you will be able to operate the winch from the driver’s seat.

The next step is to grab everything you’ll need for the recovery operation which, in this case, includes winch extension rope, tree trunk protector, soft shackle, bow shackle and two recovery dampers. If you only have one recovery damper, you can use a heavy jacket or your winch recovery bag as the second damper.

Move the winch’s clutch lever to the free-spool position and then pull out enough winch rope to reach the anchor point. If the winch rope isn’t long enough to reach back to the vehicle, unfurl the winch extension rope and run it back to the vehicle and attach to a rated recovery point with a rated shackle. If you’re using a steel bow shackle, tighten it, then back it off a quarter of a turn so it won’t bind up while winching, which can otherwise make it difficult to remove later.

Back at the anchor point, run the winch rope (or in this case the winch extension rope) around the groove in the winch ring. Now run the tree-trunk protector around the tree as low as practicable and join the two looped ends with a soft shackle that has also been fed through the hole in the winch ring.

About halfway between the vehicle and the anchor point, place a recovery damper over the winch rope and another damper over the winch extension rope. Head back to the vehicle, re-engage the winch clutch and winch in slowly until there is a small amount of tension on the winch rope, ensuring that the rope hasn’t slipped out of the groove in the winch ring.

Also feed the winch rope back on to the drum as evenly as possible. Always keep your hands well clear of the fairlead while winching in. Once there is some tension in the set-up, check that all rigging is secure, but never step over the winch rope once there is tension in the rigging.

If you are happy with the set-up, make sure all bystanders are out of harm’s way and, if you are on your own, get back in to the vehicle with the winch controller. Start the engine, engage low-range first gear, release the park brake and ease off the foot brake; the tension on the winch rope will ensure the vehicle doesn’t roll backwards.

Steer towards the anchor point and begin to winch in, aiding progress with some application of the throttle. Always keep some tension on the winch rope to prevent it from slipping off the winch ring and keep an eye on the recovery dampers to make sure they don’t end up fouling in the winch ring or the fairlead.

Once out of your predicament and back on solid or level ground, winch out slightly to take the tension out of the set-up, secure the vehicle (put it in park or in gear) and turn off the engine.

Pack up and stow your recovery gear, feed the winch rope back on to the drum evenly and check the area thoroughly to make sure you haven’t left anything behind. While setting up a double-line pull may have taken longer than a single-line pull, it is well-worth it if you are really stuck, and if you want to minimise the load on your winch.

Winching on an angle

Snatch blocks and winch rings can be used for much more than a double-line pull. In our next winching example, we’re winching a vehicle up a track using the winch on the following vehicle thanks to some imaginative rigging.

Here’s the scenario: you’re driving up a narrow bush track in a winch-equipped vehicle and the vehicle ahead of you (without a winch) is stuck and blocking the track. To winch it forwards, you will need to run your winch rope past the stuck vehicle, through a winch ring and back to the stuck vehicle. The problem here though is that your winch rope might not clear the stuck vehicle.

The solution? Run the winch rope to a suitable anchor point that is directly ahead of your vehicle, then run it to a second anchor point that is directly ahead of the stuck vehicle, and then back to the stuck vehicle.

To achieve the above set-up, in addition to your winch and winch rope, you will need at least one winch extension rope, two strong and suitably positioned anchor points, two tree-trunk protectors, three shackles, two winch rings, three recovery dampers and, of course, enough gloves for everyone involved in the recovery procedure. It will make life easier if everyone has a UHF as well. We also used a third tree-trunk protector in this recovery operation to spread the load across both recovery points on the stuck vehicle.

The winch extension rope is attached to the front of the stuck vehicle and fed through both winch rings and then attached to the winch rope on the vehicle with the winch. The winch rings are attached to the two tree-trunk protectors using soft shackles, and those tree trunk protectors have been looped around the bases of two suitably positioned, strong trees.

Recovery dampers are positioned between the stuck vehicle and the tree ahead of it, between the two trees, and between the winching vehicle and the tree ahead of it.

This is quite a complex winching scenario, and it requires more than one person to achieve a successful outcome, but it is important that there is only one designated person in charge of the winching operation.

Once everything is in place, bystanders are clear and everyone involved in the winching operation is in a safe position, some tension is added to the set-up by winching in. The rigging is then checked again to make sure everything is secure and that the ropes have not slipped off the winch rings.

If deemed okay, the drivers of both vehicles can start their engines and get ready to begin winching. If there are no UHF radios, make sure there’s another means of communication between both drivers, such as a toot on the horn to signal start winching and two toots to signal stop winching.

When winching begins, the driver of the winch-equipped vehicle should apply brake pressure and rev the engine to assist the battery to power the winch, while the driver of the stuck vehicle should drive forward in low-range first gear to aid progress, making sure not to exceed winching speed.

There always needs to be some tension in the rigging to prevent the winch ropes from slipping off the winch rings. Also keep an eye on the position of the recovery dampers to make sure they don’t foul in the rigging, and reposition them if necessary, but only after pausing the operation. Remember, never step over a tensioned winch rope.

Although there are two winch rings in play here, this set-up is not at all like a double-line pull, and there will be no halving of the load on the recovery vehicle’s winch. In fact, there will be slightly more load than a single-line pull due to the friction as the winch ropes pass through the winch rings, so if it’s a long and difficult pull, give the winch a rest every 30 seconds or so to prevent the winch motor from overheating.

Once the stuck vehicle is out of its predicament, the recovery vehicle can winch out slightly to take the tension out of the rigging so everyone can collect their recovery gear.

Looking after your gear

Ensure you clean your winch rope and recovery equipment as soon as you get the chance. If you leave winch ropes, winch extension ropes and soft shackles muddy, they will dry out, and abrasive grit will damage them and shorten their lifespan.

Make sure the winch rope is wound back on to the drum evenly with some tension on it.

Ensure that your winch recovery kit is complete and serviceable before you head off road again. Check the condition and operation of your winch regularly, and service it when required.

Do

- Wear gloves when handling recovery equipment.

- Run vehicle engine when winching.

- Check all equipment is rated for the job.

- Monitor cable dampers and reposition if necessary.

- Have clear communication between all involved in operation.

Don't

- Step over a tensioned winch cable/rope.

- Allow spectators near recovery operation.

- Overload winch (give it a rest every couple of minutes).

- Use inadequate anchor points.

- Leave anything behind when you’re done.

COMMENTS