“The Vision EQXX is how we imagine the future of electric cars,” says Mercedes-Benz chairman Ola Källenius. “It underlines where our entire company is headed: We will build the world’s most desirable electric cars.”

That’s quite some mission statement, especially for a carmaker that effectively established the template for the modern internal combustion engine motor vehicle more than 120 years ago.

Put simply, the Vision EQXX represents a profound intellectual and technological inflection point for Mercedes-Benz. A fully functional prototype that explores the outer limits of electric vehicle efficiency, connectivity, and production feasibility, the EQXX shows what’s possible when a pillar of the automotive establishment turns its massive research and development resource entirely to thinking about designing and engineering a better electric vehicle.

This Mercedes puts over-hyped, over-valued electric vehicle startups such as Tesla, Lucid, Faraday Future, Nikola, and the rest on notice.

Here’s why: The Vision EQXX has been designed and engineered to travel more 1000 kilometres on a single charge of a battery with just under 100kWh capacity, slightly less than that of the battery which powers the three-pointed star’s electric flagship, the Mercedes-EQ EQS.

In simple terms the Vision EQXX is 39 per cent more efficient than the EQS 450+ (780km driving range, 108kWh battery) and 21 per cent more efficient than even the most frugal Tesla, the base Model 3 (491km range, 60kWh battery).

This Mercedes changes the conversation around EVs away from today’s almost total focus on driving range as a function of battery capacity, to being a function of a holistic approach to vehicle efficiency. And there are good, practical reasons for this approach, says Adam Allsopp, advanced technology director at Mercedes-AMG High Performance Powertrains (HPP): “In effect, we fitted the energy of the EQS into the vehicle dimensions of a compact car.”

That long tail flatters to deceive: The Vision EQXX is indeed a compact car. Its 2800 millimetre wheelbase is 76mm shorter than that of a Tesla Model 3, and right between those of the current A-Class and C-Class sedans. By way of comparison, the EQS rolls on a 3210mm wheelbase.

HPP, which designs and builds the fiendishly complex and highly efficient Mercedes Formula 1 hybrid powertrains at its facility in Brixworth, England, worked on every element of the EQXX drivetrain to reduce energy consumption and losses. HPP also designed the EQXX’s power inverter, and the electronics unit is the same one HPP helped develop for the Mercedes-AMG Project ONE hypercar.

To reduce its size and weight, the EQXX’s battery dispenses with the conventional method of packing cells into separate enclosed modules, and has a lightweight top cover made from sugar cane waste reinforced with carbon fibre – a materials technology used in Formula 1. Tipping the scales at 495kg, the battery has an energy density of more than 200Wh/kg.

Mercedes says this high energy density comes, in part, from the chemistry of the anodes, which have a higher silicon content and an advanced composition that means they can hold considerably more energy than commonly used anodes. The battery also has active cell balancing, which means power is drawn evenly from all cells. The EQXX system is very high voltage – more than 900V, well above the industry standard of 400V and even the 800V used in the Porsche Taycan.

The battery is only passively cooled, by the airflow under the car. How practical is that? “We want to find out,” says EQXX powertrain engineer Tim Wölfel, disarmingly reinforcing the idea the EQXX is a proper working concept, not motor show eye candy.

“What we are thinking is that each battery cell heats itself, and if we know the cell well, we can control the temperature of the cell. A lot of resource is being put into this. We have to find out what is the best state of charge.”

The Vision EQXX is powered by a single 150kW e-motor mounted at the rear of the car and driving the rear wheels. The e-motor is based on the eATS unit that currently powers the compact EQA hatch and the newly launched EQB SUV, but it has been extensively reworked with the help of HPP engineers. “The motorsport guys count every joule of energy,” says Wölfel, who points out the EQXX’s drivetrain is 95 per cent efficient.

Mercedes aerodynamics specialists say 62 per cent of the energy stored in the battery of an electric vehicle will be consumed simply by pushing it through the air on an average long-distance drive. That simple stat is the reason the EQXX has a drag co-efficient of just 0.18.

In profile and plan view the EQXX has the classic teardrop shape of extreme wind cheaters such as GM’s ground-breaking EV1 and the Volkswagen XL1 hypermiler. Both cars were referenced by EQXX engineers, along with Mercedes’ own 1938 540K Streamliner, the Concept CIII of the 1970s and the Concept IAA unveiled at the 2015 Frankfurt Show, all of which boasted drag co-efficients of 0.19 or 0.18. To get that shape the rear track is 50mm narrower than the front, and the cabin tapers dramatically above the car’s voluptuous hips.

Up front, a shutter system will open to allow air to pass over a cooling plate for the e-motor if needed. Air is also directed around the front wheels to form an air curtain and help keep the flow attached to the side of the car to reduce drag. The long tail helps reduce wasteful turbulence in the car’s wake, with an active rear diffuser that automatically lowers and extends at 60 to 70km/h to help keep the speed of the air coming from under the car equal to that streaming off the sides and top.

The EQXX’s body is made from ultra-high strength steel to improve occupant protection in the event of a crash. The doors are made from a hybrid of carbon and fibreglass reinforced plastics with aluminium reinforcements. A new polyamide foam reinforces the lower edge of the door and optimises energy absorption in a side-on collision. The roof is covered with solar panels.

Some of the most innovative bits of the EQXX’s structure is stuff you can’t see, such as the large cast aluminium component that extends from the rear floor and provides mounting points for the rear suspension and the e-motor and forms the inner rear wheel wells.

This casting is made using a patented process called Bionicast that creates a structure that mimics the load and strength paths of natural organisms, reducing excess material to a minimum. As a result, there isn’t a single straight line or flat surface on the part.

The Bionicast process, which has been used to create the front shock top mounts on the EQS, eliminates material from anywhere it’s not needed to preserve structural integrity, which means the EQXX’s wheel-well inner elements are full of large holes.

To fill them, Mercedes uses a plastic sustainable plastic substitute developed by an Israeli startup called UBQ Materials that’s made from typical landfill rubbish, such as; food and garden waste, as well as mixed plastics, cardboard and even disposable nappies. The combination of the Bionicast process and UBQ patches can reduce the weight of large structural castings by 15 to 20 per cent, according to Mercedes

EVs, even high-performance ones like Porsche’s Taycan Turbo S, aren’t usually hard on their brakes because a lot of braking is done using regen. The EQXX is thus fitted with coated aluminium brake rotors rather than steel or carbon composite units. The aluminium rotors save 13 kilograms over conventional steel units and are considerably less expensive to make than carbon composite ones.

Other innovative weight saving tricks include the use of fibreglass-reinforced plastic (FRP) rear springs. Unlike the simple FRP leaf used on Chevrolet Corvettes from 1984 to 2019, however, the EQXX springs look like 100mm wide, 13mm thick strips of plastic folded into a serpentine shape. Developed in partnership with German supplier Rheinmetall Automotive these strange looking pieces are said to be much lighter than conventional coil springs.

Behind the EQXX’s beautifully styled flush wheel covers are ultra-light, 20-inch forged magnesium alloy wheels. They are shod with specially developed Bridgestone Turanza tyres that are also lightweight and have ultra-low rolling resistance.

All this attention to detail has kept the overall mass of the EQXX to around 1750kg, says Mercedes-Benz. By way of comparison, that’s just 138kg more than the base single motor Tesla Model 3, which has about 60 per cent the battery capacity and can travel less than half as far between charges, and 730kg lighter than the single motor Mercedes-EQ EQS 450+.

Once you get past the easy wins in terms of aerodynamics, powertrain optimisation, and weight reduction, the efficiency devil is in the details. And the EQXX brims with clever technologies and features that are designed to help the car extract the most performance from every joule of energy it consumes.

The 117 solar panels on the roof of the EQXX feed into a 12V system that powers many of the car’s ancillaries. On a good day, says Mercedes, the system will lower the draw on the 900V system enough to deliver a 25km bump in the range.

Sensors around the car monitor the airflow so the EQXX can calculate the positive or negative impact of changes in wind direction on energy consumption. Combining all that data with detailed terrain and traffic information, the EQXX will constantly calculate and display a speed that delivers maximum efficiency.

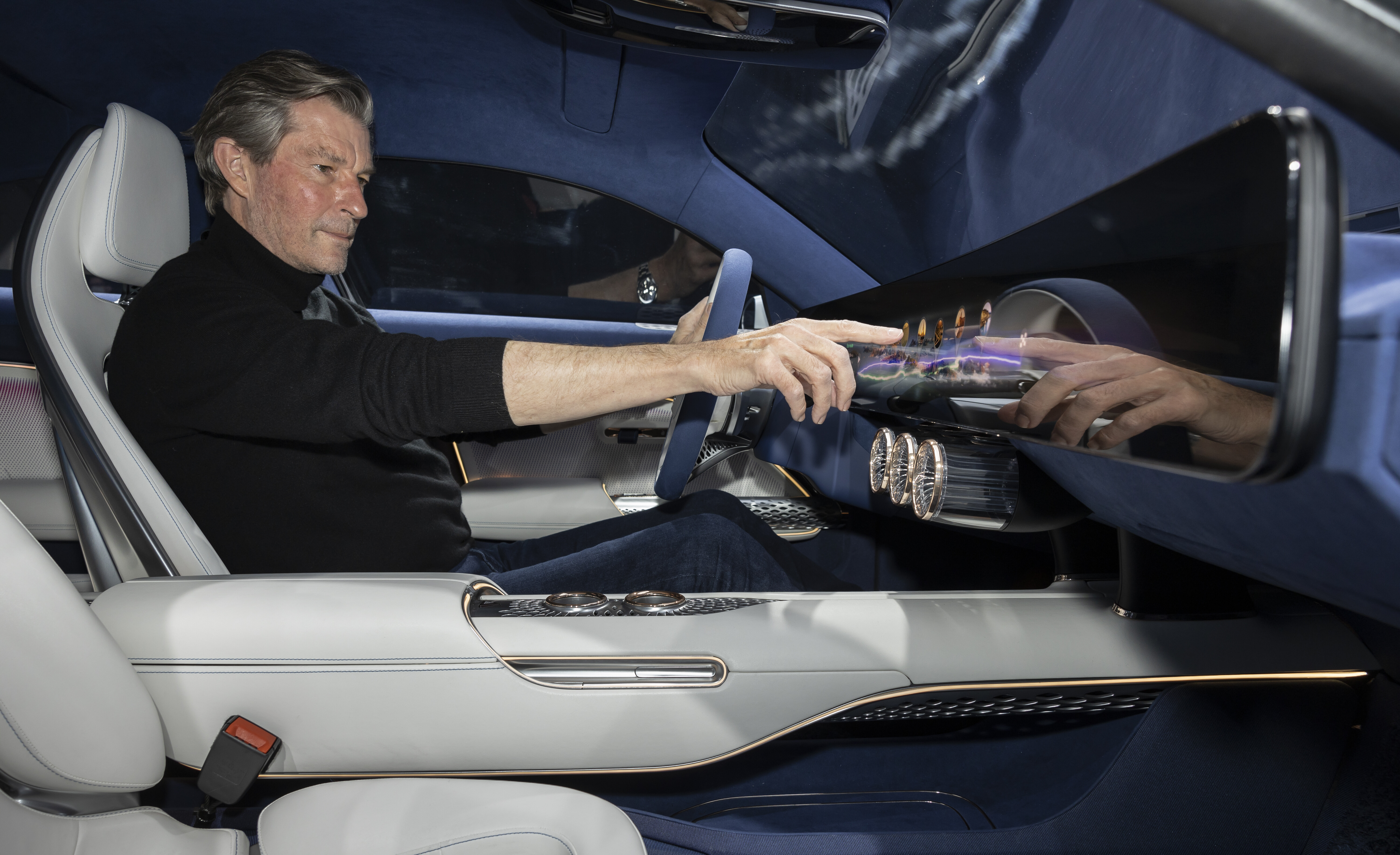

The curved 8k screen that stretches between the A-pillars makes the most of the EQXX’s crisp and sparkling game-engine-powered graphics, including a real time 3D navigation display. The mini-LED backlit screen features more than 3000 local dimming zones, which means it only consumes power as and when specific parts of the screen are in use. The EQXX has conventional external rear view mirrors because engineers concluded a camera system like that used on Audi’s E-Tron would consume too much energy.

Some parts of the beautifully finished EQXX interior, such as the steering wheel and gear selection, wiper and indicator stalks, are from existing Mercedes production cars. Everything else is bespoke, and almost all is wrapped in cutting-edge, environmentally friendly materials. The fabrics and leathers and carpeting, for example, are made of either plant-based organic materials or recycled plastics.

The door pulls are made from a vegan-certified biofabricated silk. The seats are trimmed in an animal-free leather made from pulverised cactus fibres combined with a bio-based polyurethane. Seat cushion details are covered in a vegan leather alternative made from mycelium, which is the underground rootlike structure of mushrooms.

The floor carpets are made from 100 per cent bamboo fibre. Recycled PET bottles used in a shimmering textile to enhance the floor area and door trim, while an artificial suede made from 38 per cent recycled PET has been used to create a wrap-around effect linking the upper edge of the one-piece screen with the doors and headliner.

The relentless pursuit of energy efficiency extends right down to the way the car’s electronic brains process information. The EQXX features a neuromorphic computer network developed in conjunction with California-based artificial intelligence developer BrainChip.

Neuromorphic computing is a form of information processing in which hardware runs what are known as spiking neural networks. These artificial neural networks mimic natural neural networks, firing only when certain thresholds are reached. Mercedes says the system measurably reduces energy consumption. One small example: The “Hey Mercedes” voice control system in the EQXX is five to ten times more efficient than in current Mercedes production cars.

Mercedes acknowledges that while neuromorphic computing is still in its infancy, it says similar systems will be available in a variety of consumer products within a few years. And when applied at scale throughout an electric vehicle the technology has the potential to significantly reduce the energy needed to run the artificial intelligence technologies that will help control the EVs of the future.

The Mercedes-Benz Vision EQXX might be a concept, but the ideas and processes that shaped it are grounded in production reality. “The technology programme behind the Vision EQXX will define and enable future Mercedes-Benz models and features,” insists Mercedes-Benz board member and chief technology officer Markus Schäfer. “And the way we developed it is as revolutionary as the vehicle itself.”

Indeed. A new digitally-led design and engineering process saw the EQXX go from idea to road ready in just 18 months, bringing together expertise from the company’s Formula 1 and Formula E race engineering groups, its research department and prototyping specialists, and the production development team.

Mercedes-Benz invented the car. Now it aims to reinvent the electric car. As such, the Vision EQXX may well prove one of the most consequential concept cars of the early 21st century.

We recommend

-

News

NewsMercedes-Benz announces Vision EQXX reveal date

The German manufacturer believes its car can do 1000km on a charge

-

News

NewsMercedes-Maybach EQS concept breaks cover in Munich

Maybach’s first all-electric production car rides high on the EQS platform

-

Reviews

Reviews2022 Mercedes-Benz EQB 350 4Matic review: First drive

The latest in a growing range of EQ-branded electric vehicles for Mercedes-Benz is still months away from Australian showrooms – but we've driven it. Here's what to expect