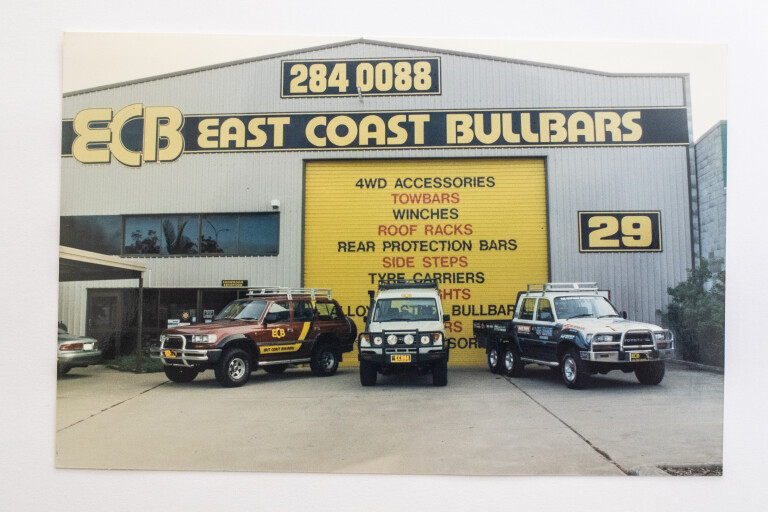

A fencing company in Clontarf, Queensland, seems an unlikely starting point for one of the Australian four-wheel drive aftermarket industry’s continued success stories, but that is where the genesis of East Coast Bullbars (ECB) occurred.

Yep, that’s right – a humble fence post was, in fact, an integral part (really, the only part) of the birth of this iconic company, thanks to the original owners who, in 1972, ran a successful fencing company. So how does a fence post start Australia’s first bullbar manufacturer? Well…

A beginning takes shape

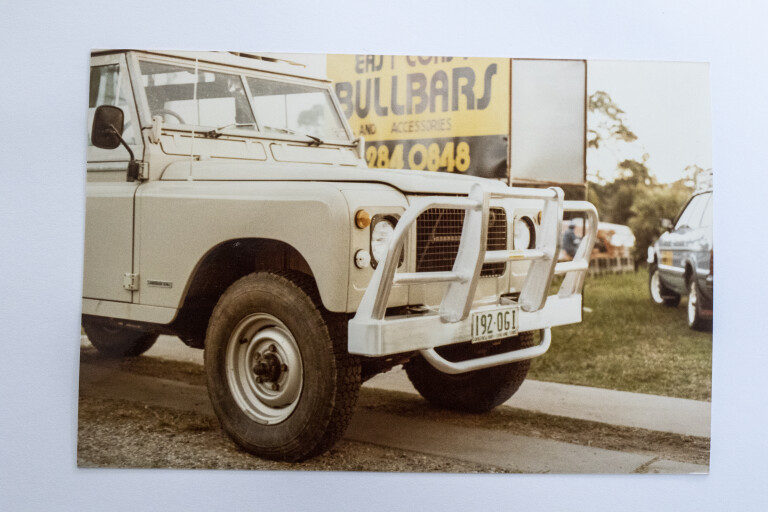

The original owners had a ute – pretty much an essential rig for any fencer – and saw the need for some frontal protection for the four-wheeled workhorse.

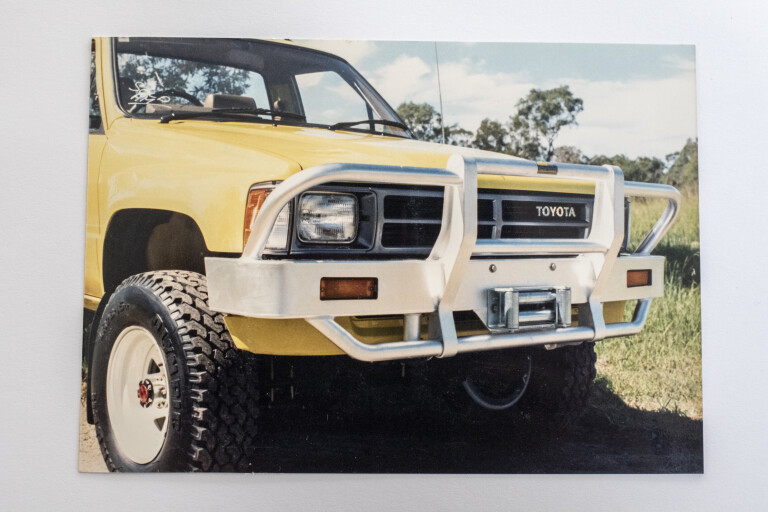

To this end, they decided to use some aluminium fence post material, which resulted in the first bullbar channel coming from a fence post extrusion they commonly used, with the upright posts and some tubes made from the same materials added to create an alloy bullbar.

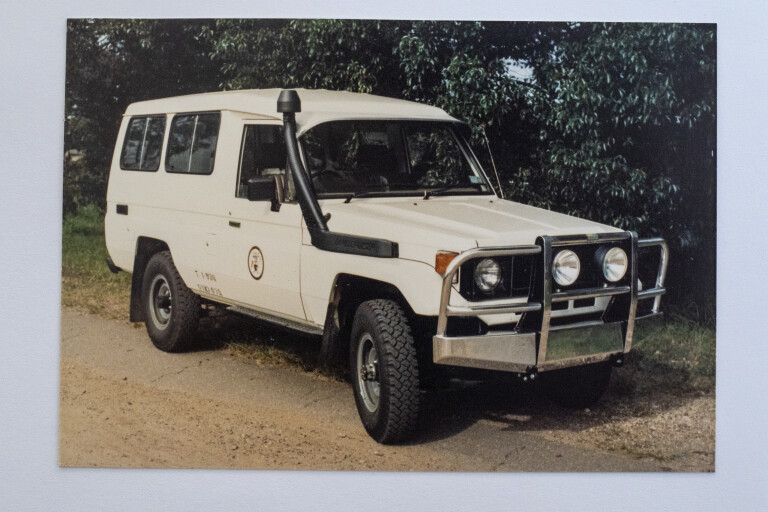

This led to a desire to expand the business to ‘bullbars’. Today, 50 years later, ECB is releasing frontal protection products for an average of 40 vehicles each year, all shaped, welded and polished (more on this later) at its Clontarf facility.

As the business began to grow, more new products were added, such as side-steps and roof-racks – all made from alloy – but the company found, later, that the time taken to produce these took time and attention away from ECB’s core business of bullbars. Thus, in the early 2000s, ECB moved away from side-steps and roof racks to focus directly on frontal protection.

A material choice

In today’s world there is an obvious focus on the environment, but ECB, with its use of alloy as its material of choice from its beginnings, could be viewed as well and truly ahead of the game.

Not only is alloy 30 per cent lighter, and thus ‘easier’ on the vehicle with tyre and brake wear and tear and improved fuel economy, plus in terms of carrying the additional weight of that accessory (which can, in some instances, mean you don’t need to upgrade your suspension to cope with too much additional weight). It is also incredibly strong and, notably, is resistant to rust and corrosion, of course.

Add in the fact that alloy is more commonly recycled (and, if you want to get in to the real nitty-gritty, has a lower melting point, meaning less power is used when recycling it) and it’s not hard to nod your head when ECB states that it was ‘environmentally friendly before it was a buzz-word’, because it simply was.

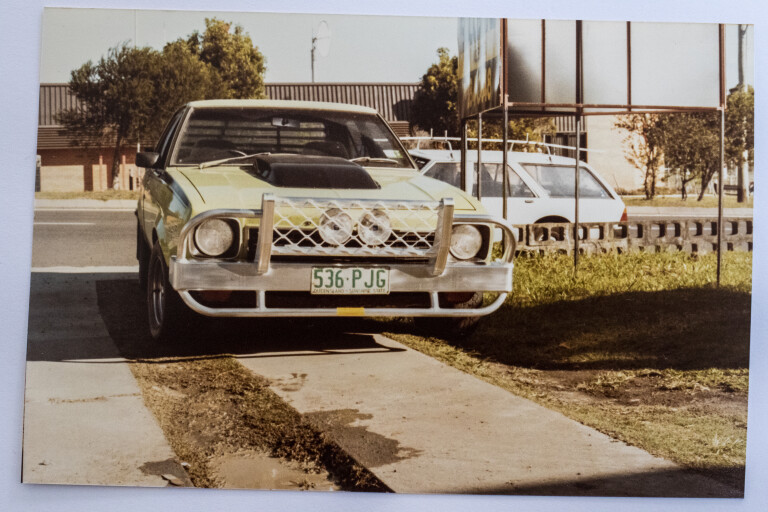

The light weight of alloy is also the reason behind ECB’s impressively expansive product catalogue; sedans (back in the day, Holden’s Torana was one vehicle that ECB made a bar for, as was its market nemesis, the XB falcon), SUVs (think: Subaru’s Forester) and hybrids (that can have a lower carrying capacity than internal-combustion equivalents) all benefit from still being able to access the benefits of fitting a frontal protection system, without the heft of a steel bar.

Of course, the company is not the only brand making alloy bars, but its formidable reputation over the five decades has led to it being the first choice for a lot of vehicle manufacturers when they’re looking for OEM product, to the point that this market segment, along with the 4x4 aftermarket (and the transport industry) has led to ECB having the largest range of frontal protection products in Australia.

The power and the passion

In today’s world of international conglomerates and a global marketplace, it is heartening to see some brands still stick to their roots, and ECB is a great example, keeping all its Research & Development (R&D) and manufacturing in Australia.

The company’s Clontarf headquarters hosts more than 80 employees, and inside is an interesting mix of old and new in terms of how ECB bars are designed, constructed and then – still, to this day – hand-finished.

This homegrown ethos also means ECB is more often than not the first brand to market in terms of frontal protection for new-model vehicles and model updates; every part of the manufacture process being in-house provides the advantage of a fast response to any changes.

It sounds like bloody hard work when you think of anything with a manual-work element in today’s lazy world, but it’s something ECB considers integral to its success. And it must be pretty awesome working there as there are a number of employees that have clocked up multiple decades.

Bar-work ain't simple

Kevin Aland, ECB’s R&D manager, has been here for 19 years now, starting on the factory floor as a tube bender, one of the first employees back then to use the new tube-bending machine (until that point, the tubes had been bent by a manual hand bender).

Kevin can remember some of the big changes at the company as he moved through different roles. From bender, he moved to welding, purchasing, production manager and then head of R&D, where he has been for the past 14 years.

“It was much smaller when I started,” he recalls. “When I first started, the R&D section was me, and now I’ve got five guys and we have a very comprehensive forward plan.”

As the company grew, so did the demand on its designers and manufacturers, with Kevin noticing huge changes in his 19 years, including things like fabricators moving from building up a bullbar on a flat table by measurement (and taking 18 months to two years to get their head around the product) to now having specific jig set-ups for different bars. This totally transformed the building process and meant a qualified welder could just start at the company, work in a welding bay and be producing products straight away.

“Machinery has changed a little bit – and the method of building has changed a lot,” Kevin says. “It’s gone from hand built – literally built by hand – to building in jigs, where it’s pretty much drop it in the jig, check measure, and then weld. So, the way it’s been built has changed a great deal.”

Technology has not only assisted ECB in finessing its workflow and end-products, but it has also brought up a few more challenges for bar designers compared to the ‘old days’ of just fabricating a bar and bolting it to an old Landy or Cruiser, as Kevin explains.

“I was around for the first time when a parking sensor went in … It was an absolute nightmare, and took an extra three to four weeks on top of the R&D,” he laughs.

Today, it’s a faster process, with the focus on ensuring the bar doesn’t impede any of a vehicle’s safety features.

Along with hearing about all the tech advances (CNC tube cutters and laser cutters, for example) in how ECB now produces its bars, it’s heartening to also hear that, even with all that, the company’s hands-on approach is still present throughout the manufacturing process (design, welding, etc.) and, literally, in the form of the hand-polishing teams who are responsible for that famous ECB shine.

As Kevin explains, even that is now a faster process thanks to some new technology, with the constant focus being on the end-game of delivering top-notch products to customers. And that is simply a combination of hard-working teams throughout the stages of the bar-making process, combined with the implementation of new tech.

“ECB are continuing to invest in new machinery and manufacturing process capabilities that will take the business into the next 10-year phase,” he explains.

“This will ensure manufacturing ability continues to grow and develop as the vehicles change with the rise of EV and PHEV.” Yep, it’s all about improvement. And, now that you mention it …

Future changes

It would be easy for this well-established company to just forge ahead, continuing to produce the same high-quality products for years and years into the future, but that’s not how ECB has ever really worked in the past – or now.

Rather, the company has, instead, just taken a huge step in to a whole new design DNA for its bars – note the plural there – as ECB has developed a range of three separate bar designs, and is kicking off that range with a three-model offering for Toyota’s all-new LandCruiser 300 Series, with more vehicles to be covered very soon.

The three designs include a traditional three-loop winch bullbar, a two-post winch bullbar and a single-loop winch bullbar. Proving the company continues to not only innovate, but be smart and wily with it, the two-post winch bullbar design reflects what ECB has learned from its past products.

“If you look at the two-post bar,” Kevin says. “Its design was tested to the same strength as the three-hoop design, and used on Hinos and Canters that travel in high-impact areas”. That’s an impressive level of strength and is just what a lot of tourers (and other types of drivers) are looking for in terms of frontal protection for their vehicles.

This three-model range reflects ECB’s aforementioned thinking around different driving styles, needs and locations (itself the result of plenty of customer feedback). As Kevin says, it covers any driving scenario, “that is made for areas … outside Brisbane with small wallabies, all the way to grey nomads out doing the ring of Australia who may encounter a two-metre kangaroo in the centre of the road.”

Additional features in this new range include inbuilt rated recovery points, the ability to add a 22-inch LED light bar inside the bar’s main channel, underbody protection, and more.

Of course, ECB will continue to produce its lauded range of nudge bars, including the 76mm Nudge Bar and Series 2 Nudge, with new shapes and designs.

Fifty years strong, and growing stronger

Looking back over the five decades East Coast Bullbars has been in operation, there are any number of highlights, with a few standout moments and the company’s overarching ethos of quality, innovation and, above all, a sense of community within the walls of its factory.

Indeed, it is the passion of its employees that is most notable, with a far higher percentage of staff retention than a lot of Australian companies, across all industries, reflected in the amount of time some of its long-timers have been there – up to a very impressive 36 years.

It is Kevin who sums up the whole ECB story perfectly, though, when he says how impressed and proud he is of all his fellow staff-members and how they really look forward to going to work each day and want to produce the absolute best product.

In short, with ECB, it comes down to passion. Looking back, that’s not hard to understand, either. After all, it was the original owners’ passionate belief that a fence post could be a hell of a lot more than what it seemed that started the whole thing, so it’s fitting that ECB keeps that passion and love for innovation and improvement moving for the next half a century.

COMMENTS