CARBONFIBRE is a composite material comprised of two key ingredients. Fine fibres provide enormous tensile strength and component stiffness, while a resin holds the fibres together and helps form the part’s shape. Since it was invented, manufacturers and material specialists have been increasing the strength of carbonfibre by improving the fibre volume fraction; the ratio of carbon to resin. The more fibres you can squeeze into the component, the stronger it becomes. It’s also more consistent. A void of resin within the material (or even worse – an air bubble) is a weakness, so filling more of the space with fibre also reduces the chance of component failure.

That’s where Lamborghini’s ‘forged’ carbonfibre comes in. Instead of hand-laying many sheets of fibre mat into a mould, which is labour intensive and can introduce defects, a mixture of chopped fibres and resin is forced into a closed mould. The extreme pressure excludes air and excess resin and allows intricately shaped components to be produced.

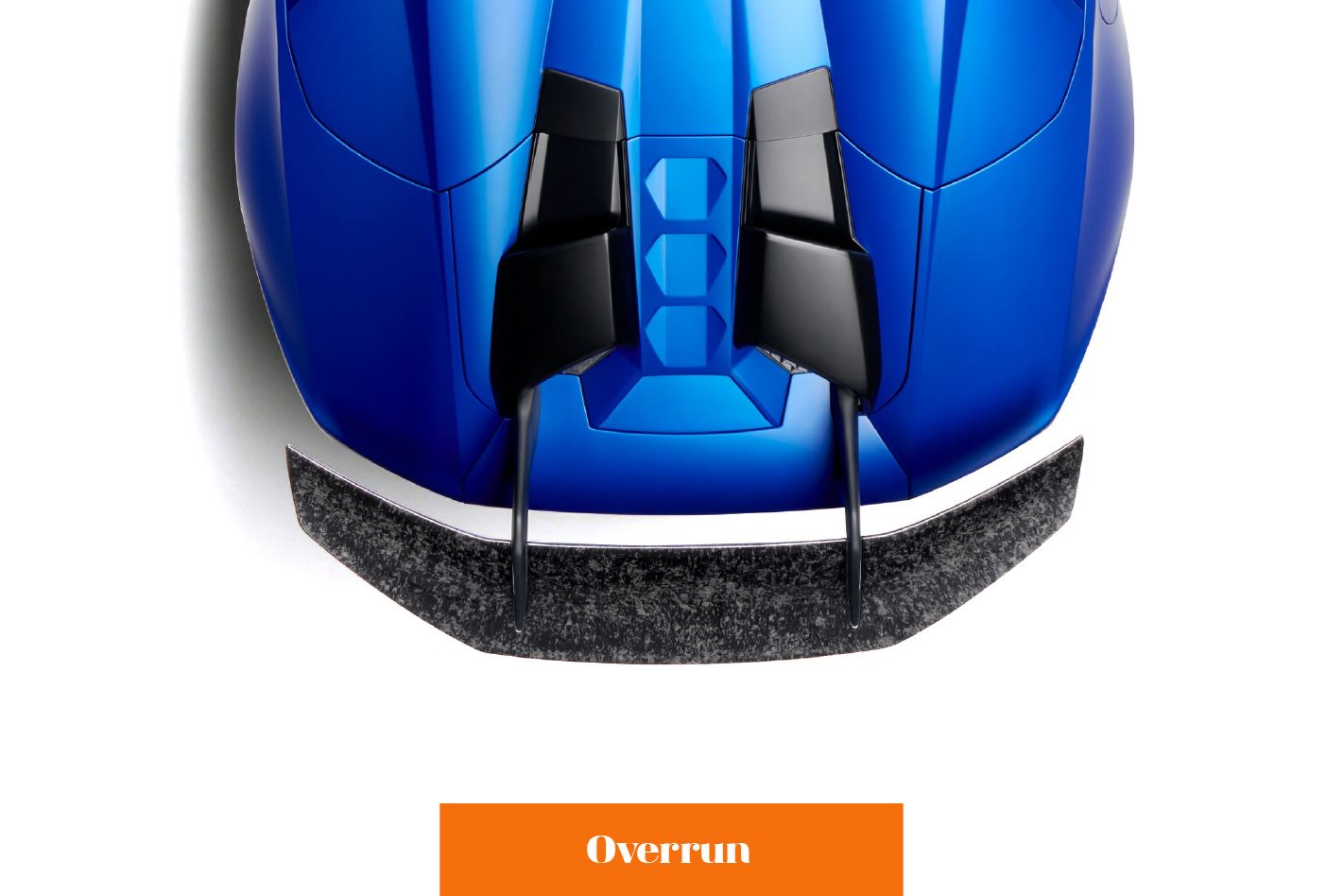

The Lamborghini Huracan Performante’s spoilers and fins are perhaps the most well-known application of the material, but Lamborghini has also produced prototype suspension arms and even con-rods. The aesthetic difference is immediately obvious. Instead of the trademark woven appearance of traditional carbonfibre, forged carbon has a random fibre arrangement and a unique marbled look.

It’s lighter, stiffer, more reliable, looks cool and it’s driving down the cost of high-tech composite materials. That’s why you’re going to see a lot more forged carbonfibre in many applications, including cars.

Driving further

Golf equipment manufacturer Callaway partnered with Lamborghini to develop forged carbonfibre, and the resulting high-tech clubs took a little Lambo influence for their name too. Callaway says its Diablo Octane drivers will drive a ball eight metres further than the previous model.

Strong connections

With a density one third that of titanium but greater in strength, the potential of forged carbonfibre is obvious. Lamborghini’s next-gen V12 is likely to get forged carbon con-rods; around 50 percent lighter than current steel components. That means lots of revs and big power.

Light show

Forged carbon debuted at the 2010 Paris motor show with the reveal of the Lamborghini Sesto Elemento. Its suspension arms and monocoque used the forged material and the car’s name translates to ‘sixth element’, a reference to the atomic number of carbon.