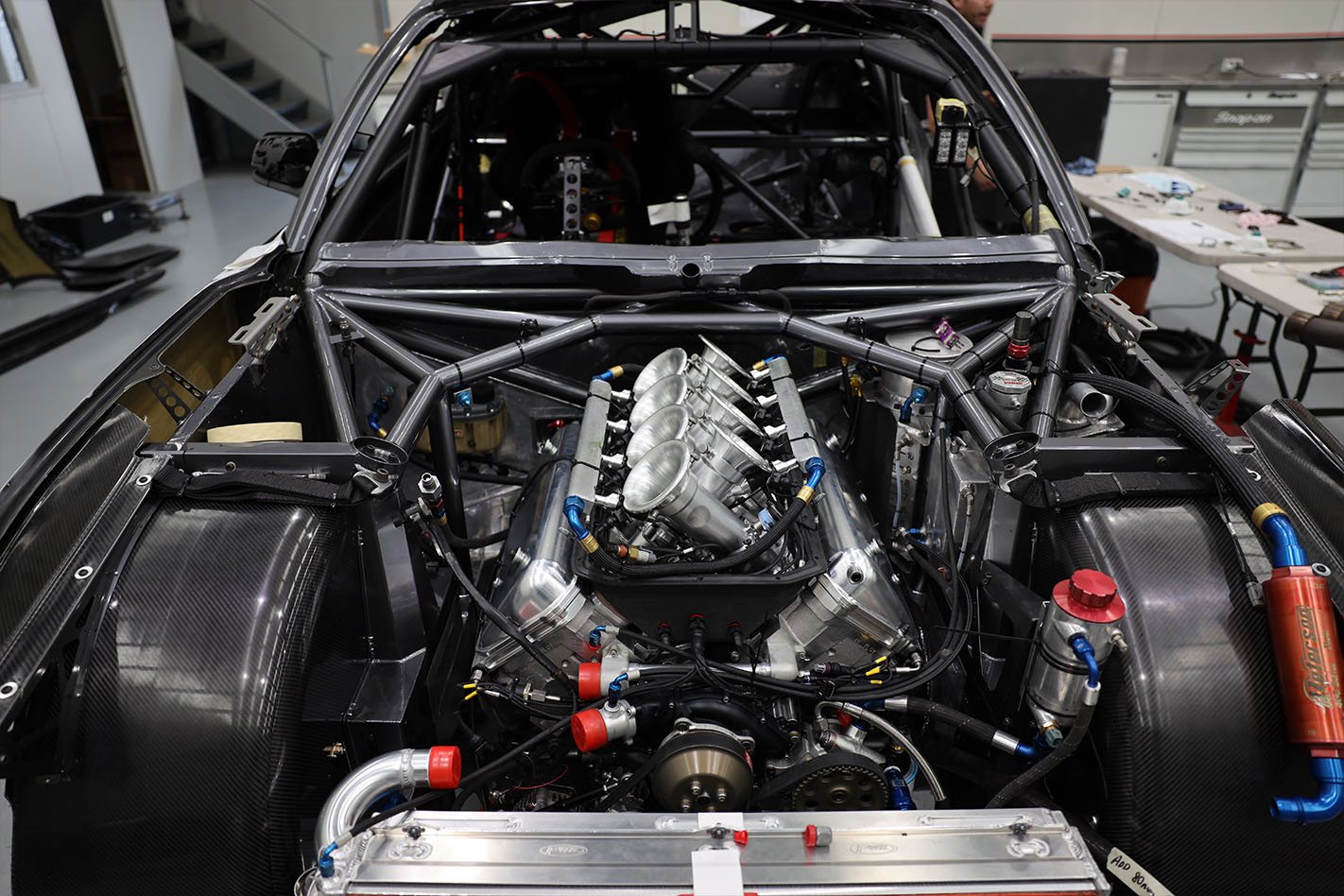

The 2022 Supercars grid is likely to see the introduction of new, modern engine technology, after almost three decades of 5.0-litre pushrod V8s.

Before anyone starts panicking, the V8 engine layout will remain, but the current pushrod engine designs look set to be replaced.

Ever since the introduction of Group 3A regulations in 1993, Australia’s top-flight category of touring cars have been powered by 5.0-litre V8s, with the current units producing in the region of 485kW. These are electronically limited to 7500rpm, and have a compression ratio of 10.0:1.

Both the Ford and Holden engines are based on American pushrod designs with two valves per cylinder. When Nissan, Mercedes, and Volvo competed in the category, each used hydraulic-lift valves, with four per cylinder.

However, for the Gen3 ruleset, due to be introduced in 2022, Supercars is looking to replace the pushrod units to a more modern design that is more affordable to run and maintain.

This means the pushrod designs will likely be replaced by direct-injection, DOHC, 32-valve designs.

“The actual engines, for the performance they produce, the noise they make, the spectacle that they provide, they do an amazing job,” Supercars’ chief strategy officer John Casey tells Wheels.

“But race engine technology has moved on substantially. There are now many more options available.

“More contemporary configurations are available to us, which are much lower maintenance, provide less stress, and are therefore less expensive and so on.”

MORE ON THE FUTURE OF SUPERCARS

- Ford could leave Supercars if Holden isn’t replaced

- Examining Gen3 Supercars rules in detail

- Where to next for Supercars

It is thought that a ‘crate’ engine formula, with teams using ready-to-run engines, could be implemented.

There is some debate about where the new engines will be sourced from, how many options will be available, and how much they will cost.

Currently,Supercars’ engine costs are described as “out of control” by those in the pit lane.

Garry Rogers Motorsport was forced to leave the sport last year, partly due to skyrocketing costs, with team leader Barry Rogers (son of the eponymous Garry) saying maintaining and developing the current generation of V8 engine makes up a large part of the expenses associated with being competitive.

“For a two-car team, running engines for the year costs near enough half a million dollars,” he tells Wheels.

“You can buy a crate engine for about $40,000. You can get through a year on two of those.”

Triple Eight Engineering boss Roland Dane believes it is time for Supercars engine regulations to be revised, with a slight drop in power likely to net teams significant savings without hurting the racing product.

“The engines that we have got at the moment are the product of many years of development, taking something that never should be able to produce the power that they do,” he explains.

“They are overly stressed and therefore need rebuilding more often than is ideal, and also cost too much in the first place.”

Dane is opposed to the term ‘crate engine’ but recognises that there are more affordable options available to the category than what is currently in place.

The pit lane heavyweight referenced Triple Eight’s experience with GT3 racing, where it fields a Mercedes-AMG GT GT3, as an example of how engine performance and associated cost can be better controlled.

“The engines in those cars they produce in GT3 form around 410kW, but they can produce 447kW in a heartbeat without the restrictor,” he adds.

“Those engines are V8 naturally aspirated, and do 20,500km between rebuilds. That is getting on for double what a Supercar season is likely to be in the future.

“At our highest mileage engine so far at 12,000km we haven’t seen any decrease in performance. None. It is perfectly possible with modern technology and modern engine architecture – double overhead cams not pushrods – to get to the level that would give us a power to weight ratio to still make our cars difficult to drive so you and I will struggle with them.

“If they are too easy to drive, they will lose an awful lot of their appeal.”

It is understood that Supercars is currently evaluating the suitability of current crate engines to be used in the category, such as Ford’s 5.0-litre Coyote V8.

Dane’s ideal scenario would be for teams to still choose what engine they run in their respective cars, instead of a one-size-fits-all situation.

“What we want is a V8 naturally aspirated engine that produces a very similar power to weight ratio to today,” he says.

“It is no question we can make a car lighter than we do today, and therefore we can have a power to weigh ratio that is similar to today, but with a bit less horsepower than we have got today. That then makes it easier, and gives you more choices – whether it is one engine or two, or you allow people to bring an engine in. That is something Supercars is still debating.

“They have all got to be, obviously, paratised and equalised in terms of performance and fuel economy.”

Veteran racer and team co-owner Todd Kelly also believes that a slight power reduction is needed to help lower engine costs going forward.

“The engines in the cars are so technical and expensive to design and build and run and maintain. And it doesn’t have any impact on the end product,” he explains to Wheels.

“You could have 15 less horsepower, have just as good a racing, and save half a million dollars a year on your engine budget.”

Kelly Racing has competed with Holden, Nissan, and now Ford engines under current regulations, and Todd supports a regulation change.

“Our rules are currently built around getting a heap of components and then spending 25 years building something amazing,” he says.