The grand opening of Norweld’s new 2367sqm factory in Brisbane welcomed more than 2000 people through the gate for a sneak peek, with a line-up stretching down the street before the 9am kick-off.

Driving into the event, the canopy envy was very real as Norweld-equipped dual-cabs lined the streets of the Brendale industrial estate as far as the eye could see. Once inside, food trucks, free coffee and a DJ in the back of a Jeep offered plenty of fun for the entire family, but the real drawcard was the impressive array of custom 4x4s on display - of which there were dozens.

The number of businesses that turned up with their latest builds, to show support, was immense, with everything on display from heavily customised American pick-ups to decked-out Aussie Troopies.

Pro Touring Concepts had some of its tough new builds there, including a no-expense-spared Ford F-250 that drew a revolving crowd and dwarfed the sea of 79 Series LandCruisers surrounding it.

Norweld staff also hosted tours of the factory, showing off the low-waste manufacturing line, with cutting-edge machinery on display like a new high-speed CNC router, advanced press brake, and an array of top-end welding equipment.

Massive giveaways drawn throughout the day kept crowds excited, with first prize being a Norweld Deluxe Plus Tray worth around 15 grand, which the guys will fit to whatever ute the winner owns. Second prize was a Torqit exhaust system and third prize was a Redarc 240W solar blanket, and huge crowds congregated for each draw with fingers crossed.

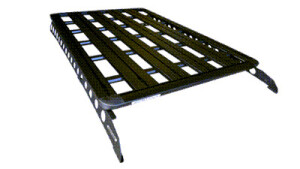

Latest Gear Guides

In case those prizes weren’t enough, the Norweld team drew names out of a barrel every hour after giving every attendee a ticket at the gate. Door prizes included Norweld’s latest range of merchandise, with goodies like fishing shirts, hats, t-shirts and heaps more.

While we can’t reveal too much just yet, Norweld also had its next-generation Elite Tray on-show, fitted to the iconic ‘Bull79 3.0’ LandCruiser, reborn once again and looking better than ever.

The Bull79 ‘Cruiser, which belongs to Norweld special projects director, Isaac Edmiston, is as tough as it looks with 37-inch tyres, portal axles, big power and now it also wears the manufacturer's latest heavy-duty tray.

The new tray is set to be launched in early 2024, with the first customer examples expected to land on customer vehicles by March. While we can’t show photos of it just yet, we can confirm it looks the goods.

Norweld expansion

Norweld will still build all of its canopies out of its Far North Queensland factory, with this facility set to churn out trays and accessories, which makes sense given the Brisbane 4x4 market is the strongest in Australia.

“We started doing components here in Brisbane, making toolboxes and stuff across the past six to 12 months, but this is the first time we’re doing full production here,” said Jaime McIntosh, Director at Norweld.

“Brisbane is our biggest market in Australia, so we wanted to get close and, as far as four-wheel drives are concerned, there are a lot of complementary services around Brendale.

“Our plan is to get to 40 trays per week out of here, and we’ll do about 20 canopies each week out of Cairns."

The site will also house a slick new showroom and plenty of office space, serving as the Norweld head office with marketing, sales and design teams now operating out of the one location.

Norweld has more than 20,000 of its trays and canopies out in the wild so far, all with lifetime warranties, and its customers are clearly happy campers after seeing the overwhelming turnout on the day.

When Jaime purchased the company in 2001 it had a strong reputation for high-quality fabrication, but it wasn’t until 2015 that he decided to focus solely on trays and canopies.

“When I bought the business we had six staff in a small shed, and we’d punch out whatever we could,” he said. “Did I think we could get to this size - no, not at all.”

These days, Norweld employs 120 people and expects that number to grow considerably as the new factory ramps up production.

“We have 20 people at this facility in Brisbane and that will get to 30 relatively quickly and then probably 40 by the time we reach full production,” said Jaime.

It isn’t just about quantity, though, because Norweld’s reputation is founded on building the toughest trays and canopies out there.

“It’s almost a problem in that we build them so tough and we offer a lifetime warranty, but people still want the latest designs and we can customise older models,” said Jaime. “It’s a quality product and it’s handmade, so it’s not just about quantity for us.”

In recent years Norweld has also exported a number of its products to the US, South Africa and even Saudi Arabia, but Australia remains the core focus.

“We’ve sent them all over, but the main export market has been the US,” Jaime said. “We send a container there every three months, which is about 16 trays and the odd canopy. There’s a big market there, but we still have a lot of growth here in Australia.”

When discussing products in the pipeline at Norweld, Jaime hinted at a new canopy design but couldn’t share too many details just yet.

“The new trays will be a big thing that is coming, then the next will be a change to the canopy,” he said. “We are always looking at different ways of doing stuff and we’re potentially looking at going to a modular fit-out for the canopies, so you can add and change it.”

While the sheds just keep getting bigger to keep up with Norweld’s explosive growth, Jaime reckons this one will offer enough space for the foreseeable future.

“My wife keeps asking, ‘when’s the shed going to be big enough’ because they keep getting bigger and bigger,” he joked. “This one is probably close to our limit!”

COMMENTS