YOUR next high-end sports car could feature seats, wheels and even a complete body built from carbonfibre parts all made in Geelong.

The former home of Ford in Australia is fast shaping up as a carbonfibre heavyweight, with the CSIRO announcing today that it had developed the cutting-edge technology to make enough of the super-strong, ultra-light material in Geelong to start up a car factory.

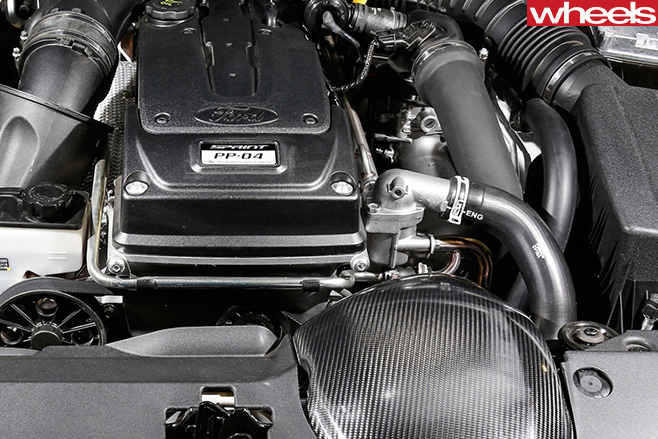

Not only that, but the company that developed the airbox for the last of the Aussie-made Ford Falcons now says it wants to build car seats from the same stuff.

The CSIRO today unveiled a locally developed, scalable “wet spinning line”, a technology developed with Deakin University that only a handful of companies globally can pull off. It will be based at Waurn Ponds, just outside of Geelong, on what the CSIRO describes as the “Ferrari of wet spinning lines”.

Meanwhile, Quickstep, the company that made the carbonfibre airbox and intake for the Ford Falcon Sprint series, will start developing car seats from the futuristic material.

CSIRO said the wet spinning line machinery took a “sticky mix of precursor chemicals” and turned it into 500 strands of fibre, each thinner than a human hair.

“Only a handful of companies around the world can create carbonfibre, each using their own secret recipe,” the CSIRO said in a statement.

“Until now, Australia didn’t have that capacity on an industrial scale to take carbonfibre from resin, from like chemicals in a jar,” CSIRO spokesman Chris Still said.

“What it essentially means is that you can make carbonfibre from scratch in Australia.”

Still said Geelong’s “Carbon Valley” was taking the region in a “whole new direction” in manufacturing.

So could this mean Australia could start making cars again?

“Well, we’ve never lacked the capability and there’s unfortunately plenty of empty factories lying around. But in terms of the carbonfibre side of things, yeah.”

Quickstep’s three-year project will tie in with a “global seating and interior systems supplier”, believed to be Futuris, to develop new seating systems using a $1.45 million grant from taxpayers.

“Carbonfibre composites remain niche products in cars primarily due to the high cost of materials and manufacturing, despite the weight reduction, improved performance and aesthetic appeal they provide,” Quickstep said.

“This project aims to solve these problems by combining product design with advanced manufacturing and materials research, to deliver a bespoke materials and process solution for lightweight carbonfibre seats.

“This will create a new benchmark in high production rates and performance at lower cost.”

The two projects join Carbon Revolution, a carbonfibre wheel manufacturer. It has won a contract to supply lightweight rims for the Ford GT, as well as the Ford Shelby GT350R Mustang.