It’s a common thing to see chequebook builds these days. Brand-spanking 4x4s with the local off-road shop catalogue thrown at them, often within a few weeks of ownership.

Some folks like to drop a bunch of coin on their rigs for tax purposes, or maybe they just want to get it all done in one fell swoop, or maybe they just like spending money and want their rigs to look tough.

For Dylan Brechbuhl, building up his 2014 HiLux was a much slower process. It’s not that he didn’t have the money so much as he wanted to make sure he was investing the time and effort into the right places.

So he stayed patient, worked out exactly what he needed and fit or built it so that it would suit his needs perfectly.

Which, let’s be honest, is arguably the smarter way of doing things – there’s no point in dropping several gorillas on 400A of lithium when all you’re powering is a couple of LEDs and a small fridge on the occasional overnighter.

Now that his Luxy is getting close to done (not that they ever really are, of course) he can sit back and be proud of what he’s created, with the help of a few good mates along the way.

Working the body

In a world full of dual-cabs, it’s sure nice to see the single-cab flag still being flown. Other than the loss of occupant room, there really are a lot of advantages to the shorter bodies.

First, you actually get a useable tray (come on dual-cab people, you know that anything longer than one of your Grandpa’s stories about how he invented gravity won’t fit in your tray), plus the overall vehicle weight is lower so performance is increased; and once your ears are past an obstacle off-road you know there are no more panels to damage so you can punch it. It’s surprising there aren’t more of them out there.

Dylan first picked up his HiLux on cheese-cutter tyres and the standard white-on-white paint job as seen on job sites all over the world. It had lived the first 170k of its life as a Coca-Cola service vehicle, so the maintenance had been on point with no off-road work. Overall, it was in top condition.

The kicker was the steel enclosed service body tray it had on the back, which suited Dylan perfectly.

He’d wanted somewhere to store his tools during the week and load up with camping gear on the weekends; but he didn’t want to tow a trailer with him, so the enclosed canopy was ideal.

Unfortunately, the steel tray was heavier than a Dr Phil episode about obesity, so it was regretfully sold off, leaving Dylan a bunch of blank real estate that needed building on – but we’ll get to that in a sec…

Before deciding on a tray, Dylan wanted to get his Lux standing out from the sea of standard colours, so he did some carpentry work for a couple of panel-beater mates in exchange for laying that beautiful BMW Nutmeg Bronze down on the panels.

As anyone who has done a paint job before knows, the actual painting is only about 5 per cent of the job; the rest is all in the prep. So Dylan got busy with the block sander and high-fill and painter’s tape, before his mates came by and laid the colour down for him and the main panels were ceramic flow-coated to get it all nice and glassy looking.

Like most people who do their own paintwork Dylan swears he’ll never do it again, but the hard work paid off, because it looks nothing short of spectacular.

Sorting the bolt-ons

The HiLux came equipped from Coke with a TJM bullbar and a set of HID spotties, but that didn’t suit Dylan’s vibe, so they were yeeted and replaced with a schmick hoopless front bar from Buds Customs, and a set of nine-inch HardKorr LEDs and a pair of four-inch units lower in the bar.

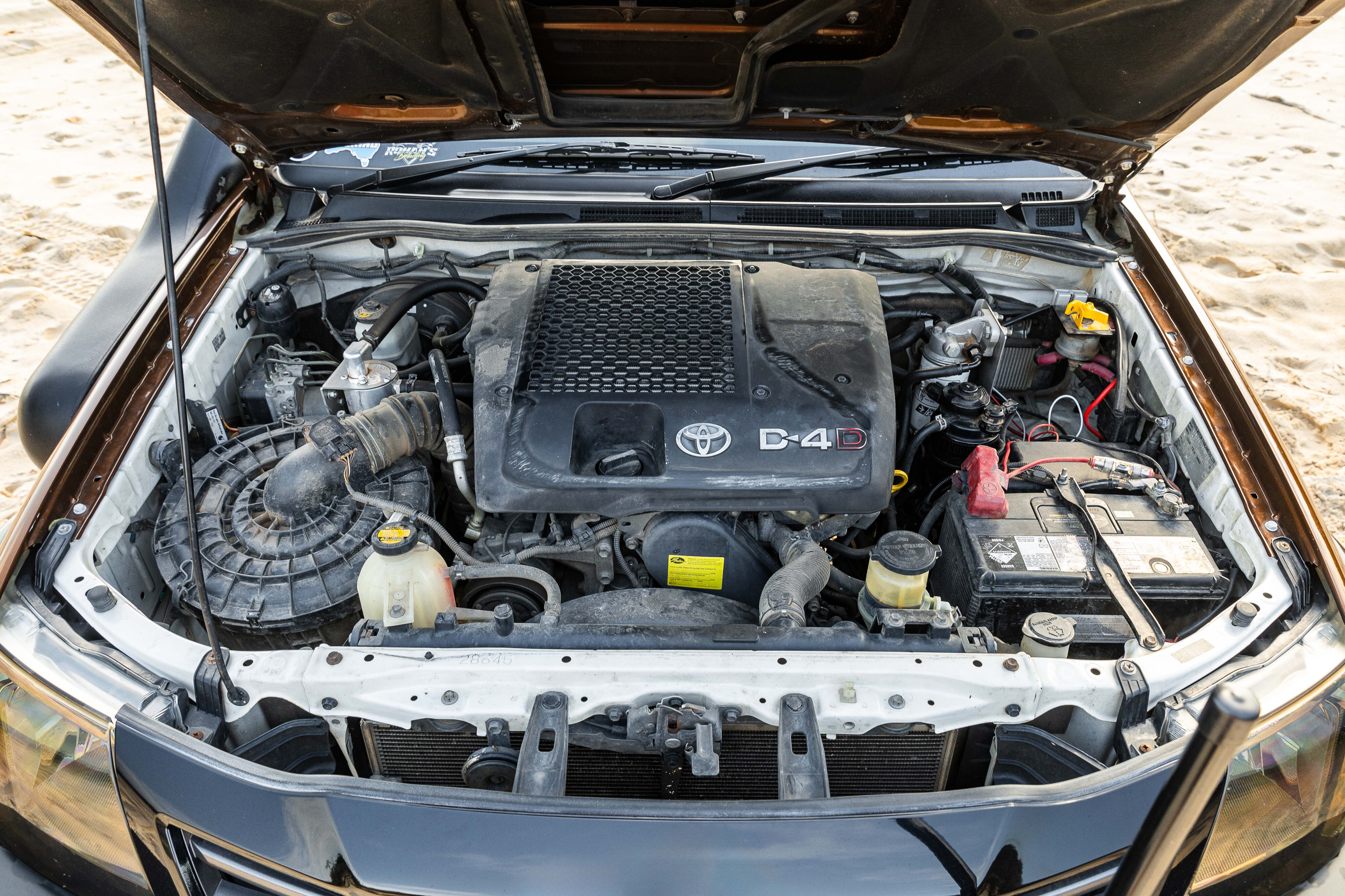

The venerable 1KD 3.0L turbo-dizzle remains stock for now, other than the three-inch PPD Performance exhaust, Safari Armax snorkel and PPD catch-can and pre-filter. Don’t be too surprised if by the time you read this Dylan has turned up the wick a little.

With the heavy steel tray gone, the suspension was all out of whack, so Dylan threw in a set of Holden Colorado RG leaf springs with 190mm shackles out back – which are longer and allow for more flex – as well as a set of PSR long-travel shocks designed for an N80, and a set of helper bags for the heavier loads.

The front has a set of Phat Bars Bilstein edition struts with King coils, adjustable upper and lower control arms from SuperPro, and a Phat Bars diff drop to keep the CVs from dynamiting themselves.

The standard skinny rubber and steelies were introduced to the bin and replaced with some slick 17x9 KMC-machined alloys with a satin black outer ring, surrounded by 285/70R17 Nitto Ridge Grapplers.

The underbody is also landmine-proofed via Phat Bars 5mm steel bash plates that are sturdier than Taylor Swift’s bank balance. Should Dylan’s world suddenly become inadvertently inverted, there’s a half-cab steel roll bar fitted courtesy of the good folks at Coca-Cola.

Sussing the tray

While the tray is first and foremost built for purpose, it also happens to be better looking than a Friday-arvo frothy.

Custom made from aluminium to keep the weight down, the whole show was shortened down to 2200mm, with a 1200mm-long Magnum canopy keeping the 150Ah second battery and Bushman upright fridge out of the elements. The whole thing has been braced and strengthened to take the VTX Offroad roof-topper and hang the HardKorr 270° wraparound awning.

Drop-down sides at the rear make loading heavier items a bunch easier, and the under-tray toolboxes on either side have been built with matching angles to make everything look seamless.

LED tail-lights and camp-lighting add more practicality, while the paint has been tirelessly blocked, sanded and sprayed to match the body by Dylan and his mates, who also Raptor-lined the underside and wet areas of the tray.

Dylan, being a chippie, built his own two-drawer set-up in the canopy for tools, clothes and sleeping gear, leaving enough space for bulkier items to be stored on top. The passenger side is in the process of having a slide-out pantry and drop-down table built (again by Dylan), which will make camp food-prep that much easier.

What's up next?

As with most builds, the to-do list on Dylan’s rig is still longer than your arm.

Water tanks, long-range fuel tank, a pair of Recaro butt-huggers, a locker or two, and maybe even a rear coil conversion for increased comfort.

Oh, and maybe a 12V upgrade and a nicer rooftop tent while he’s at it. But as we said, he’s not the type of bloke to rush these things. He’s too busy being out on adventures and enjoying his rig. The way it should be.

Thanks

Dylan wanted to thank Nomad Welding for the tray build, CJ Fabrication for the under-tray boxes, Roam Gear for his 12V set-up, HardKorr for the awning and lights, as well as a couple of good mates for their help with the painting and suspension install.

COMMENTS