With 15 years of experience producing Wrangler products, American Expedition Vehicles (AEV) has prided themselves on being a “Jeep” company, one that specialises in components that are engineered to work in concert with each other.

Their objective has been to provide the enthusiast with a one-stop source for the highest quality parts – rather than having to patch your rig together with products that may or may not be the best match. This year they’ve deviated from the Jeep-only mantra with the introduction of a new line of innovative products for Ram full-sized trucks. That line culminated in the development of this exquisite example of automotive art: The AEV Ram 2500 Ute.

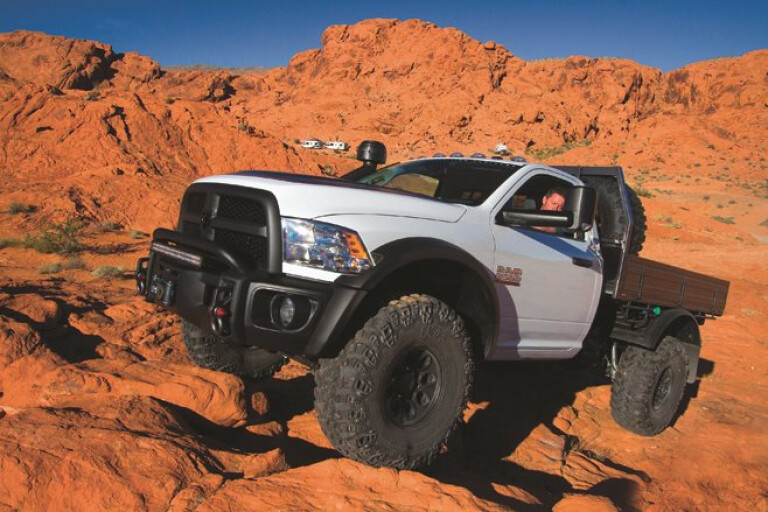

On initial glance, the Ram Ute appears like any other lifted truck with a cool bumper and big tyres. However, closer inspection reveals a plethora of nuances that separate it from the Bigfoot crowd. Firstly, though it rides on 41-inch Interco IROK Super Swamper tyres the Ram isn’t that high. In fact, the suspension system raises the vehicle a mere three inches.

Any shop can toss a few leaf and coil springs together, throw a drop Pitman arm and some shocks in a box, and call it a lift kit. It is true that this will raise the vehicle, allow for larger tyres, and provide a feeling of superiority as you look down at an intersection full of loathsome soccer-mum-mobiles. But buyers beware, soccer mums may have the last laugh on the highway when your patched-together lift won’t track straight and induces an SS Poseidon effect in turns. With thousands of street and off-pavement kilometres in various AEV-equipped vehicles, we assure you this is not the case with the suspensions hailing from this American-born company from Montana.

We crawled under the front end of the Ram with AEV owner Dave Harriton, and he explained that their goal was to break a decades-old methodology of lifting a vehicle: “The idea is to make the vehicle think it’s not lifted. Why mess with millions of dollars of proven engineering?”

A proper suspension system is engineered to closely mirror the OE handling characteristics, and AEV accomplishes this through a number of innovative measures. While most lift kits incorporate a drop Pitman arm or steering link, the Ram DualSport system utilises a custom bracket on the axle that raises the panhard rod to maintain its original geometry. While the OE steering arm attaches to the bottom of the knuckle, the new AEV arm attaches to the top, again retaining the factory geometry. Rather than increasing the spring length, which can lead to unusual steering characteristics during full droop, a three-inch cast aluminum seat is placed under the OE coil springs. The aluminum aspect keeps unsprung weight to a minimum, and the stock spring length allows the steering to track properly under any axle configuration.

The system incorporates the OE trailing arms, but a custom rear bracket positions the rear of the arm three inches lower (again, proper geometry) and 1.5-inches forward to allow for tyre clearance. To assist with manoeuvring the 41-inch tyres, a PSC hydraulic ram was added. The rear suspension integrates a similar combination as the front; sway and panhard bar correction, stock length coil springs, and AEV-spec Bilstein shocks are found at each corner. The result is increased ground clearance, an additional inch of up travel, larger tyres that don’t rub and a vehicle that maintains stock handling properties.

Keeping with the don’t-mess-with-a-good-thing mantra, AEV left the powertrain pretty much stock. The Cummins 6.7-litre turbodiesel generates 650hp (485kW) and 660 lb-ft torque (895Nm), more than enough to motivate the vehicle’s weight. The G-56 six-speed manual transmission (a wonderful thing) features an impressively low 6.29:1 first gear and 0.74:1 overdrive ratios. To ensure debris-free air to the engine, an AEV Raised Air Intake system was added. It functions as a pre-filter for the OE air filter, is self-cleaning, and utilises a cartridge similar to those found in heavy equipment and military applications. To compensate for the 41-inch tyres and provide four-wheel traction, the factory axle housings (AAM 9.5-inch front and AAM 11.5-inch rear) were fitted with 4.10:1 ring and pinion gears and ARB air lockers.

AEV made a splash at the 2013 SEMA show with a prototype Ram front bumper, and brand enthusiasts united in interest. We’re pretty sure they won’t be disappointed with the final version. As with many of the company’s bumpers, it is stamped from a solid sheet of 3/16-inch plate steel. Frame mounts are 1/4-inch plate and trace the frame rearward beyond the stock fittings on the end of the frame horns. Our experience has shown that this method addresses the torsional effect induced during heavy winching by distributing the load evenly to the meat of the frame. Though the winch cradle is designed for a Warn 1500-pound (7484kg) model, it will accommodate forward or bottom-mount units. Recovery points (or hoops) are cast steel, feature a nifty little skid pad, and sit outbound of the frame.

To properly distribute the load experienced during a recovery, AEV engineers developed a triangulated box-type system that creates a load path to the main mount and frame; all are 1/4-inch steel. The bumper is also of a modular design, which will allow end-users to choose from a variety of lighting and riser hoop options. Another feature, and one many bumper fabricators are overlooking on this vehicle, is the engine’s intercooler. It rides directly behind the OE bumper (which has a cutaway to allow airflow) and needs that cooling effect to function properly. The AEV unit addresses this with a cooler-width funnel underneath to allow for unrestricted airflow – though we might choose to add an expanded metal screen to protect it from rock damage.

Down back, the Ram was treated to an aluminum tray bed from Ute Ltd. Though it is seven feet in width, a bit wider than the truck’s body, it provides ample room for gear and offers the ideal platform for a camper or other abode. The stock rear bumper was exchanged for a 1/4-inch plate steel unit with integrated LED lighting, trailer wiring, and a two-inch receiver. The filler for a Titan 30-gallon (113.5-litre) auxiliary fuel cell, which hangs in the spare tyre bay, sits between the bumper and bed. The spare was re-mounted against the front of the bed with an AEV tyre carrier kit.

We were jazzed when we hooked up with Dave at the 2014 SEMA show and he offered us first crack at reviewing the Ram Ute. Whether you’re a Jeep, Toyota, or Land Rover aficionado, you’ve got to admit, it’s downright cool.

2015 Ram single cab long bed SLT Specifications

| Engine | Cummins 6.7L turbodiesel |

| Output | 650hp (485kW), 660 lb-ft torque (895Nm) |

| Transmission | G56 six-speed manual w/ 6.29:1 first gear |

| Axles | AAM 9.5in front, AAM 11.5in rear |

| Differentials | ARB air locker, 4.10:1 gears |

| Tyres/wheels | 41/14.50R17 Interco IROK, AEV 17x10in Katla Wheels |

| Aspiration | AEV Raised Air Intake with pre-filter |

| Suspension | AEV DualSport |

| Steering | AEV Hi-Steer, PSC hydraulic assist |

| Bumpers | AEV modular front, AEV custom rear |

| Winch | Warn 16.5t, AEV/Factor 55 FlatLink thimble |

| Auxiliary fuel | Titan 30-gallon (113.5L) |

| Lighting | AEV/Vision X LED |

| Ute Ltd. aluminum bed w/AEV wheel skirt | |

| AEV high-clearance fenders |

COMMENTS