Let’s cut straight to the punch. You’re looking at the most powerful Ford Ranger in Australia. By a long, long, long way.

While the internet is rife with people pushing their 3.2 Duratorqs to their limits chasing anything north of 200 rear-wheel horsepower, Michael has obliterated that with an eye watering 750hp at the rear wheels.

If you’ve come here hoping for a write-up on storage drawers and roll-out awnings you’re in for a bad time. But if forged rods, billet internals, and one-off adaptors for exotic transmissions are your kind of funk then you’re in for a treat.

Let’s get one thing clear right from the start: the original 3.2L five-cylinder turbo-diesel that came standard in Michael’s 2013 PX1 Ranger (yeah, she’s a first gen) is a distant memory.

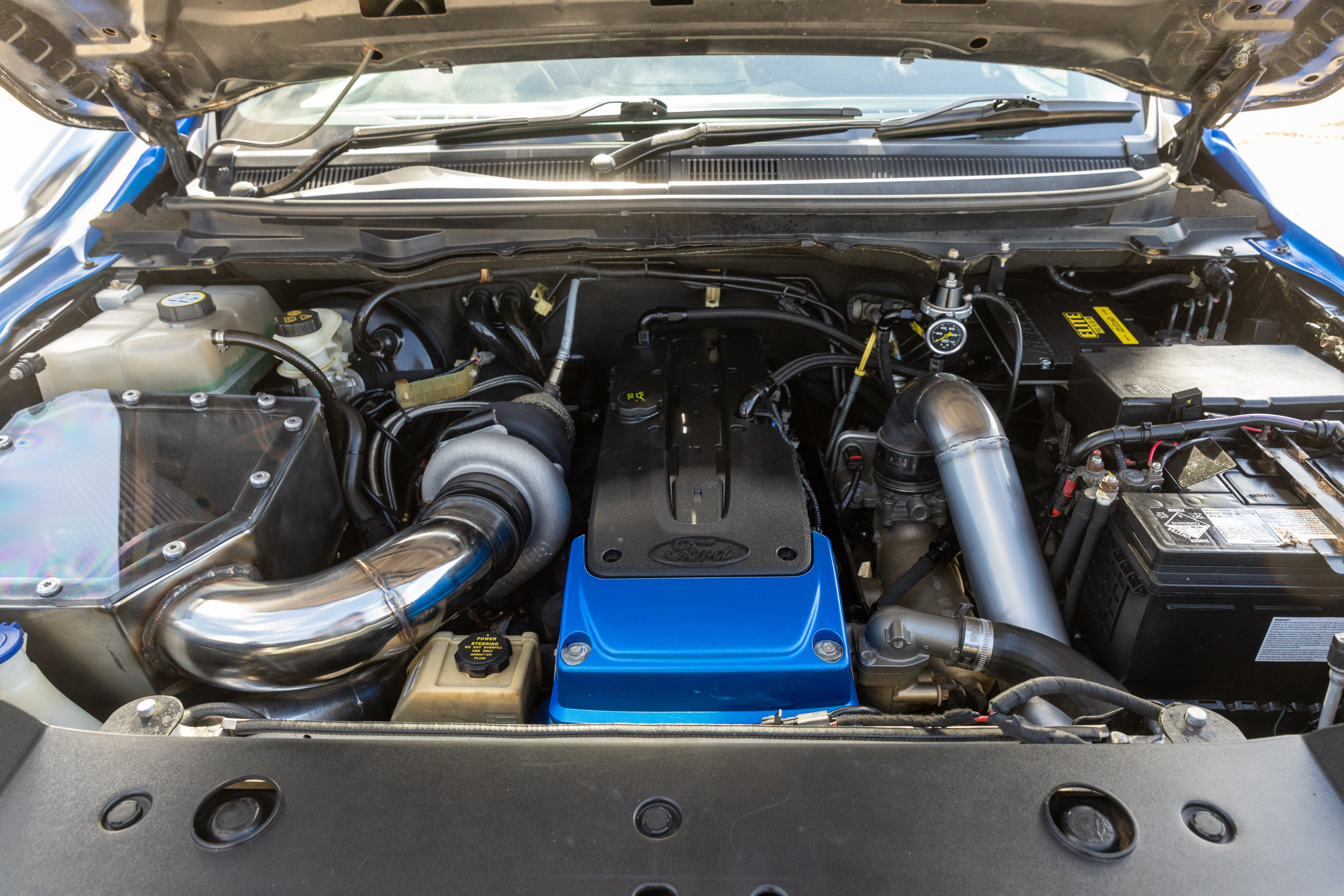

In its place is now the holy-grail of Aussie motoring: a 4.0L six-cylinder ‘Barra’. Aussie designed and built, the big-six was found in everything from naturally aspirated taxis to high-performance factory turbocharged applications, but none of them were ever as wild as this offering.

Taking an x-ray to the Barra reveals the secret to a reliable 750hp at the wheels. ACL race bearings wrap around a factory crank tasked with keeping the forged Spool rods moving freely, with matching forged Spool CP pistons on the angry end.

The combination is good for a reliable 1000hp-plus should Michael decide to wind the wick up even further.

A factory Barra head is still more than handling the power. Michael’s fitted it up with heavier duty Crow Cam valve springs to fight off the dreaded valve float. A combination of ARP head studs and an MLS head gasket keep it firmly sealed to the block even when the two-step button is fired into life.

Of course, forged internals alone don’t make horsepower, they just make the engine hold together when pushed far beyond figures that’d pretzel a stock setup. Under the bonnet of Michael’s Ranger, a Garret GTX3584r turbocharger is responsible for all the power and noise.

It’s paired up with a 50mm Turbosmart HyperGate wastegate ensuring it peaks at 22psi for reliable shenanigans.

On the back-end, Michael pieced together a work-of-art four-inch stainless steel exhaust system from the turbo back with flexi-joiners, V-band flanges, a catalytic converter, resonator, and high-flow four-inch muffler, all teaming up to give one hell of a note without offending the EPA in the process.

On the cold side, a matching stainless steel airbox and intake pipe combination play host to a huge nine-inch Stealth Extreme air filter ensuring an endless supply of cool filtered air.

Once the turbo does its work, the charged air is forced through a polished PWR charge air cooler to drop temps and increase air density, before a factory FG Falcon short-runner style inlet manifold rockets the compressed air in to meet the forged pistons.

There’s zero chance the factory fuel system would be able to cope with the demands of a 750hp package, and even less chance the factory ECU would either.

To ensure the Barra pulls strong all the way to redline, Michael spec’d up a pair of Walbro 460lph fuel pumps draughting from a 2.3L alloy surge tank and feeding into six 1000cc Bosch injectors.

Managing the whole affair like an orchestra of mechanical mayhem is none-other than Haltech’s Elite Pro electronic control unit.

“I went the Haltech for all the functions it supports,” Michael tells us. “There’s a rotary switch for multi-boost level maps, crackle and pop tunes, an anti-lag button and two-step for launch control; the Haltech was the easiest solution for all of this and to talk to the vehicle through CANbus.”

Moving backwards and Michael’s fitted up a late-model BMW automatic transmission in the form of a ZF 8HP eight-speed. A DomiWorks bellhousing adaptor marries it up to the Barra engine with custom mounts holding the combo in.

It’s paired with a standalone transmission control unit from TurboLamik giving Michael ultimate control and a bunch of neat tricks.

“I’ve got eight different driving modes,” he says. “Normal automatic mode, sports mode, sports plus, full manual… it’s got a transbrake for hard launching and even an electronic clutch mode if I want to drive it like a manual.”

Despite the trick features of the bimmer ’box, in 2WD form it wasn’t going to cut the mustard. Michael took matters into his own hands and machined up not only a custom adaptor to mate the 8HP to the factory Ranger transfer case, but the input shaft as well.

Paired up with a shortened rear shaft and extended front shaft, the 4x4 system works exactly as it used to, just with five times the power pushing through it.

Jump into the captain’s chair and it’s obvious this Ranger means business. A sequential style shifter from 8Speed sits inside the factory Ranger gear shifter location, a small LCD screen spits out gearbox data including gear position, drive mode and transmission temperature, while a boost gauge tells Michael when it’s time to calm the party down.

A huge 11-inch Tesla-style touchscreen not only updates the PX1’s dash, it also feeds into an eight-inch Pioneer sub/amp combo under the front seats, while Kicker six-inch speakers in each door hit the mid notes and a pair of tweeters bang the highs. A slimline 120Ah Kickass battery hides in behind the rear seats.

Moving to the outside and Michael’s styled the Ranger’s looks as loud as he’s built its drivetrain.

That striking blue colour scheme is no vinyl wrap; it’s a flash layer of paint Michael mixed and sprayed on himself. The engine covers copped the same treatment, because details matter, right? Hiding under that oh-so-loud paintjob is a PX2 Raptor-style conversion up front, significantly updating the looks from the original PX1 affair.

The full replacement bolt on plastic front-end was picked up for a bargain basement price off Marketplace, but looks a million bucks paired up with the SS custom headlights, and the matching rear panels fitted up over the top of the factory tub.

That polished stainless steel Fabulous Fabrications snorkel pairs perfectly with the machined 17 x 9 KMC Machete Crawl wheels.

The genuine beadlocks have a -38mm offset. For context, that’s a wheel track increase over seven inches wider than a stock Ranger. The wheels are shod in 35 x 12.5 Kenda Klever R/T tyres, with four-inch front Bilstein struts and two-inch rear lift combo courtesy of Fulcrum shocks and King springs.

With a shift in popularity from older 4x4s to newer dual cabs, a certain amount of uniqueness was lost as four-wheel drivers drifted from DIY to bolt-on camping setups.

But with these dual cabs now starting to age and come onto the secondhand market, we’re like kids in a candy store waiting to see all the amazing DIY builds people are dreaming up in their garages.

But we reckon it’ll be a while before we see another dual cab with anywhere near to the power Michael’s Ranger is punching out.

Despite being an absolute whiz on the welder, paint gun and lathe, Michael reckons one of the hardest parts of the whole build was finding someone with the skills to wire the new driveline package into the Ranger’s CANbus system, and unless you’ve tried engine swapping a late model 4x4, you’ve might never have come across the term before.

In order to understand what a CANbus system does, you first need to understand the problem it solves. In the old days, when the ECU controlled six injectors and the fuel pump, wiring was relatively straightforward. The ECU would send a signal to the pump to turn on, and if it got a signal back it knew things were working well. Simple, right?

Things started going pear shaped as systems became more complicated, with multiple ECUs, transmission control units and vehicle body computers. Having individual wiring from every component to every control unit would soon become an absolute disaster of a wiring loom that would add complexity and weight to the system.

CANbus simplifies things by having multiple components talk over the one set of wires, using a special language to identify what they are.

Instead of each wheel-speed sensor needing to be wired to the ECU, traction control system, stability control system, transmission control unit, and even the stereo to bump your music up a little louder at higher speeds, they can send a signal into the CANbus network with a little intro on where the info is coming from and what it’s saying.

The individual computers can then receive that information, decide if it’s relevant or not, and do it without a million kilometres of wiring bogging things down in the process.

Think of it like having 30 4x4s in your convoy and needing a separate radio to talk to each one, or just using the one channel and announcing who you are and who you’re talking to when you key-up the mic.

COMMENTS