"BIGGER IS BETTER.” There, we’ve said it. Even though some of us often, and for various – ahem – undisclosed reasons, always say that size is not everything, that oft-overused adage still resonates sometimes.

When you’re talking about building an off-road touring vehicle that can tow effortlessly, lug all your gear (and then some more), and negotiate the most challenging tracks while offering ample passenger comfort, that old adage definitely rings true. And that truth is what you’re looking at right here; this epic 2017 F-250 Platinum 4x4 pick-up, powered by Ford’s venerable 6.7-litre Power Stroke V8 engine, and built-up for touring and towing by Jamie Facer of Allsafe Mine Vehicle Equipment (AMVE 4x4). It is the ultimate proof of the bigger and better theory.

More 4x4 gear guides

It’s all about choice

THIS isn’t the first dual-cab tourer that Jamie has modified. Before the F-truck arrived at AMVE 4x4 HQ, he’d had a succession of Toyotas: two 79 Series utes (one dual cab, one single cab) and a trick dual cab 200 Series ute. He liked them, but thought that these vehicles were still slightly compromised – the 200 Series dual cab more so, due to the fact that the cutting of that vehicle significantly alters the Toyota wagon’s dynamics.

He brings up the fact the big Yank tank was an ideal choice, simply due to the fact these vehicles are built to purpose; that purpose being to tow and carry large loads.

“I always wanted a Ford due to the spec of the truck,” Jamie says. “The power, comfort, reputation and tow capacity.”

All of which hints at the main purpose for this Pearl White monster: on- and off-road touring throughout Australia while towing a 21-foot Kedron off-road caravan. The F-250 is impressive off the showroom floor, but Jamie had bigger plans to build the best touring F-Truck in Australia.

Tricks of the trade

DIRECT imports to Australia of the Ford F-250 stopped in 2006, but, thankfully, a host of aftermarket import and conversion companies have since sprung up to meet the ever-increasing demand.

However, this still doesn’t mean an F-250 owner has an easy time of fitting-out their particular beast; there’s a distinct shortage of aftermarket accessories available here for these trucks, making Jamie’s work slightly more difficult than usual.

The F-250’s snorkel is the perfect example; with no aftermarket versions available Jamie gave Nathan at Fabulous Fabrication a shout out to build him a four-inch stainless steel snorkel that was then coated in Raptor finish for additional protection.

It was the longer-than-usual wait for spare parts – on top of either sourcing accessories or manufacturing his own – that was the most challenging part of the build, according to Jamie, who cited the popularity of the vehicle in the USA as the main reason behind parts delivery delays. This wasn’t a huge thing, though, and gave him ample time to sort out the major changes to the vehicle, starting with the suspension setup.

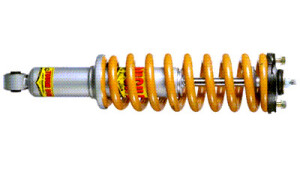

The F-250 stands four inches higher than standard, courtesy of a King Off-Road Racing Shocks coil-over system up front and a set of standard rear springs out the back that have had an additional leaf added to them, as well as a set of Airbag Man airbags and another pair of King Shocks.

It’s nothing over the top (that’s not what you want for outback travel) but it’s super-smart; having the ability to adjust the airbags in the rear means ride and handling remain unaffected regardless of whether there’s a heavy load on board or the big bopper is cruising unladen.

Another bush-touring modification by Jamie is fitment of Fuel 18x9-inch wheels, shod with 37x13.5x18 Mickey Thompson MTZ P3 rubber (he’s a big fan of Mickey Thompson tyres). The reason for opting for 18s and not going ‘fully sick’ with a set of larger 20-inch rims is that Jamie wanted more sidewall depth on the tyres to aid the load-carrying process on- and off-road.

The very personal touch

AS YOU’D expect from a company highly regarded for its canopies, tray bodies and custom 4x4 fit-outs, the F-250 sports some brilliant examples of AMVE 4x4’s handiwork throughout. The full-custom aluminium tray (with tapered channel and a one-piece mudguards, again covered with protective Raptor coating) features four very well-finished tapered toolboxes underneath (two each side, one of which houses an ARB twin-cylinder air compressor).

The AMVE 4x4 canopy includes two lift-up side doors that run the length of the canopy, with a divider in the centre of the canopy separating the fridge/freezer section (the Engel 80-litre fridge/freezer is accessed via an MSA 4x4 drop-down fridge-slide) on the left-hand side from the twin cargo drawers (one of which includes a slide-out table underneath).

The electrical work on the vehicle was the most challenging for Jamie and his team, thanks to the increased complexity of the vehicle compared to his previous Toyotas, along with the wiring itself. But you wouldn’t know it by the end product, as it looks neat as a pin. The fridge/freezer and slide section includes a great example of the AMVE 4x4 team’s exceptional auto-electrical work.

A custom panel that houses a Redarc Battery Management System (BMS) along with a combination of USB, Anderson and 12V charging outlets, as well as a 240V input socket, 2000W Redarc inverter is mounted vertically on the front wall of the canopy.

There’s access to the power of the sun, via a Redarc solar blanket, while behind the fridge/freezer you’ll find the power source of this Blue Oval Bruiser – two 160amp/h lithium batteries – housed in a dedicated box. Interestingly, Jamie opted for ARB’s new Linx in-cabin control unit to manage everything from battery voltage to airbag pressures, as well as the external lights on the big rig, plus the ARB compressor.

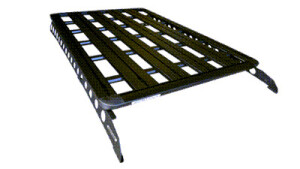

There’s more storage under the tray, with a 1500mm slide-out drawer, while a Rhino-Rack Pioneer platform adds load capacity up on the vehicle’s roof. Swinging off the top of the canopy is a shade-giving Rhino-Rack Batwing awning, while there’s also a 100-litre aluminium water tank aboard, with the liquid gold accessed via a 12V pump.

Last, but most certainly not least, is the custom-built tyre holder at the rear of the canopy that carries those two monstrous 37-inch spares.

Full body press

BIG TRIPS often mean big hours behind the wheel each day and night. To this end, Jamie has fitted protective gear and plenty of lighting for those night drives. The front bar is a Road Armor Steel Stealth jobbie, painted in Raptor coating.

As you might have gathered, the team at AMVE 4x4 are big fans of the Raptor protective coating – it’s on numerous parts of the Ford, including the aforementioned bar, the Bushwacker flares, the schmick one-piece mudguards on the cargo tray and all other metal parts.

AMVE 4x4’s own steel sidesteps keep the underbelly protected, while recovery is more than adequately covered by the 15,000lb Warn winch at the front, and another Warn winch – a 12,000lb unit – at the rear. We’d be hard-pressed to envisage this F-250 ever being stuck for too long…

Night driving means increased risk of animal collisions, so Jamie added plenty of lighting to ensure wayward wildlife is spotted (excuse the pun) before it’s too late. Two nine-inch Weldex LED spotties sit on the front bar, accompanied by a 20-inch double-row XRay lightbar.

A 40-inch double-row XRay lightbar sits atop the Rhino-Rack Platform, there are four nine-inch LED lights for side-vision, and two nine-inch LEDs attached to the tyre holder. There’s also rear-strip LED tail-lights built into the tray, which includes flush-mount reverse lights.

Built for purpose

WHEN Jamie affirms his love for full-size Yank pick-ups by saying that “nothing compares to these American trucks” he could not only be talking about these vehicles in the general sense, but more accurately also stating a fact about his own custom rig. When we ask him would he do anything differently if he built another one, the answer was short.

“Nothing,” he affirms. “Everything is spot-on and I would have no changes to make.”

The confidence reflects the attention to detail in the build. Every component on the F-250 has been well-thought-out before fitment, with the view to ensuring that, when complete, this modified beast fulfils the often hard-to-achieve brief of the ultimate long-distance, off-road touring vehicle that can, literally, take itself, a full family, the caravan and even the kitchen sink, anywhere in Australia, in comfort. And then there’s the reassurance of knowing it’ll do it as many times as you can get out there.

For those who are keen to check out this super-tough F-250 tourer in the metal, Jamie will have it on display at the upcoming National 4x4 Show in Brisbane in April.

COMMENTS