Ford is reportedly preparing a 6.8-litre pushrod V8, in readiness for the next-generation Mustang sports car.

The news comes despite Ford’s A$20 billion spend on electrification of its range, including the Mustang nameplate, over the next five years.

A trade union official in the Canadian city of Windsor – just over the border from Ford’s home town of Detroit in the US – has confirmed that one of the town’s two engine plants will be tasked with building a new 6.8-litre V8 engine, while the current Coyote 5.0-litre engine will continue to be sourced from the second plant in nearby Essex.

The new V8 is part of a wider A$2.1 billion investment by Ford, with most of the money going into the development of a battery electric vehicle (BEV) line. Some A$170 million, however, is earmarked for what’s being called a “new engine derivative”.

While it seems likely that the S650 Mustang will include a stunning all-paw hybrid Coyote V8 option, the Windsor Star is reporting that the new pushrod V8 is also earmarked for the next-generation Mustang, as well as the F-150.

Ford’s last pushrod eight-pot – also built at the Windsor plant – began production in 1962. Australia was the final market where it saw duty, finishing up with the AU Falcon in 2002.

Ford had begun the replacing the Windsor with its family of SOHC and DOHC Modular V8s in the early 1990s.

This process also included its big trucks, with the SOHC 6.8-litre V10 Triton engine doing the heavy lifting from in Ford’s larger behemoths from 1997-2019.

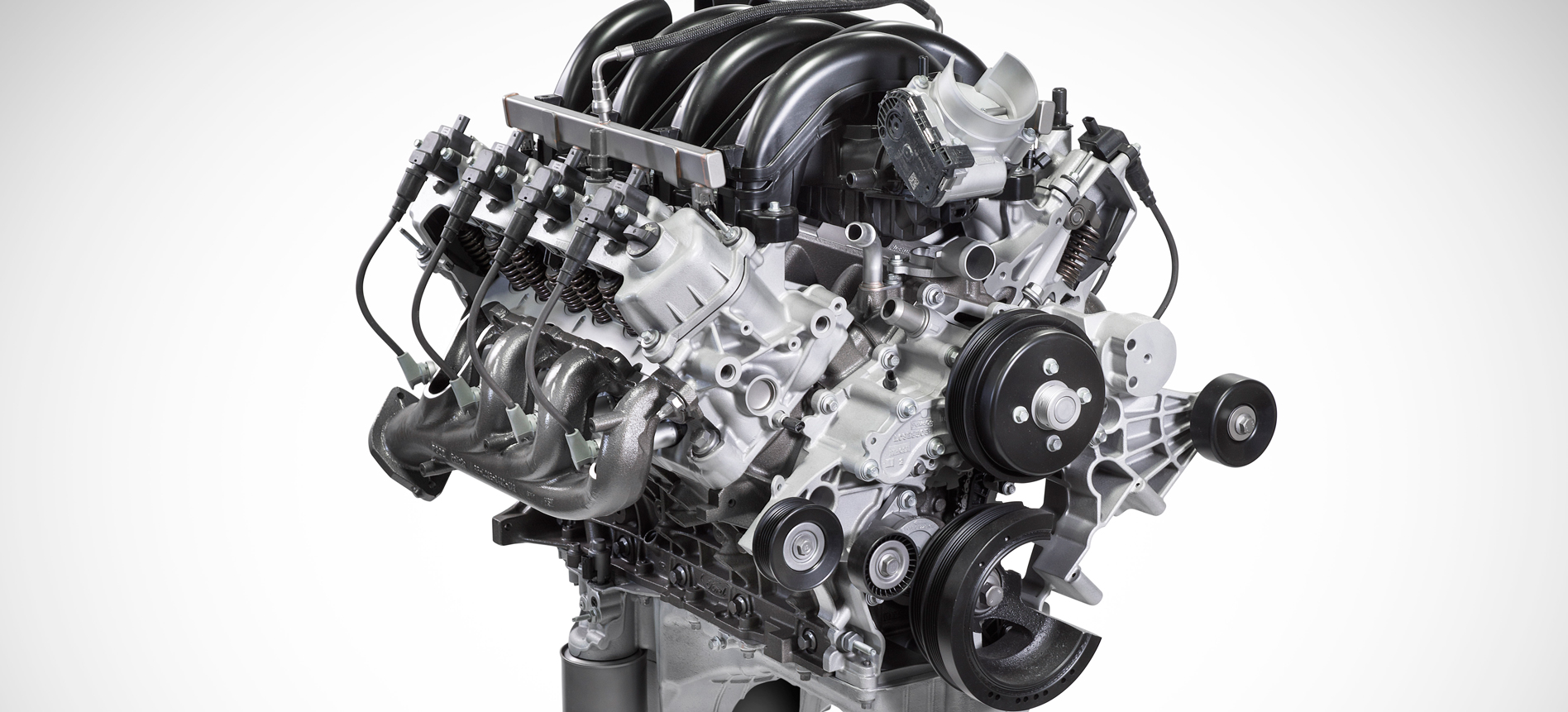

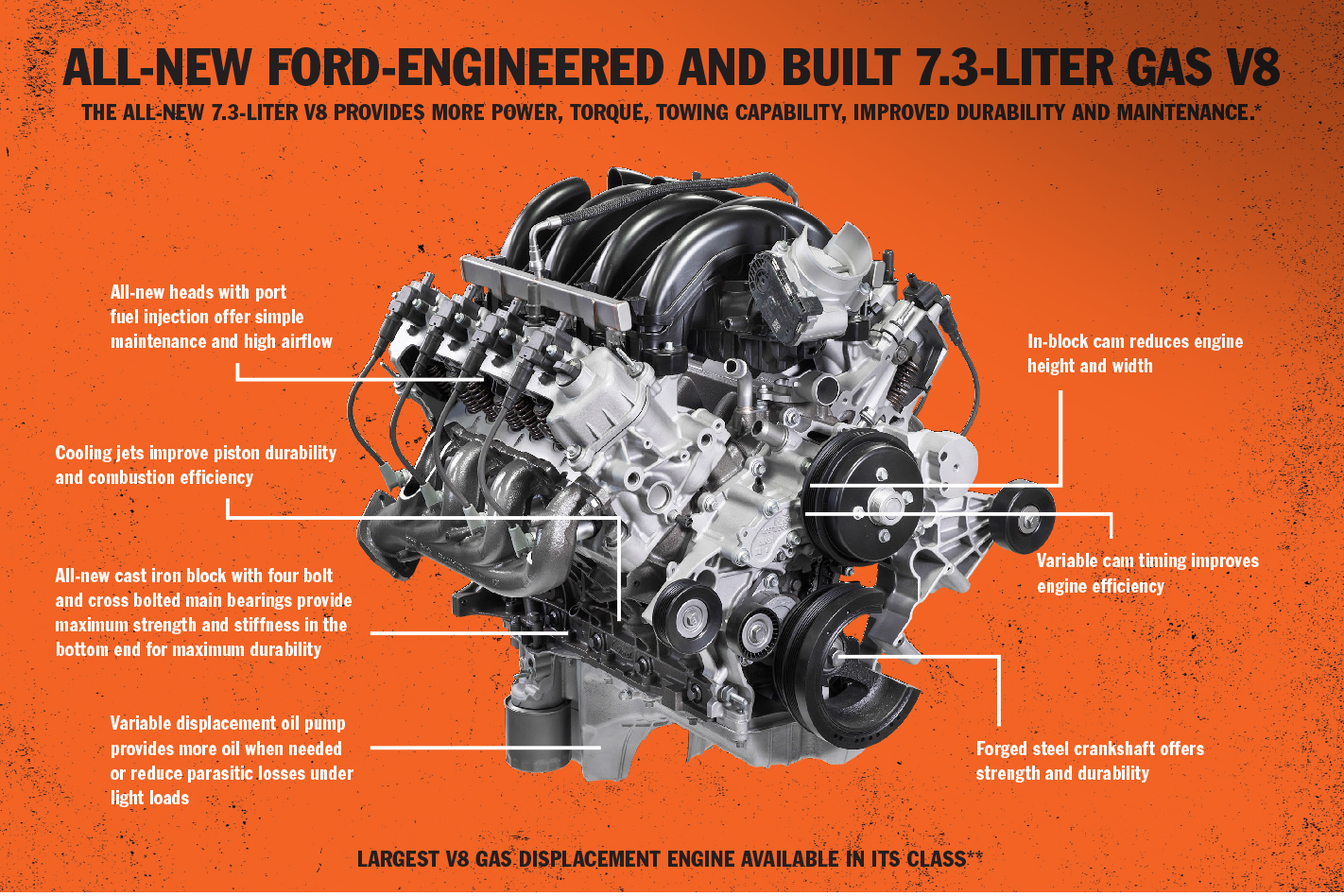

The Triton V10 was also built at Windsor and was replaced by the all-new 7.2-litre Godzilla pushrod V8 last year (above).

Given that it’s not physically possible to enlarge the Mustang’s current Coyote engine from five litres of swept volume to anything like 6.8 litres, it makes sense that the new engine announced for the Windsor plant will be related to the Godzilla lump.

Where the 7.3-litre differs from the Coyote is in its valvetrain operation.

Where the current Mustang 5.0-litre uses twin overhead cams and four valves per cylinder, the 7.3-litre relies on the old-fashioned, but still effective pushrod system, with a single cam located closer to the crankshaft and half the number of valves.

A pushrod engine won’t rev as hard as a DOHC engine and will be heavier, broadly speaking, but it is better at making torque, is more compact and uses far fewer parts.

While final specs haven’t been revealed, it seems likely that Ford would look at producing an aluminium block for the 6.8-litre engine, based on the 7.3-litre architecure.

This will take care of the reduction in swept volume, reduce the overall mass of the engine and will allow for existing ancillaries – alternators, oil systems and the like – from the 7.3-litre engine to be used without the need to redesign them.

The new casting could also facilitate the fitment of the larger engine under the bonnet of the next-generation S650 Mustang by shaving off corners and brackets of the iron block that aren’t needed.

Even so, if you are wondering how an engine originally designed for a truck will fit under the bonnet of a low-slung sports car, don’t worry – the Godzilla motor is available to the public as a crate engine and has already been successfully stuffed into a variety of Mustangs by enterprising enthusiasts.

It wouldn’t be used only in the Mustang, of course; the F-150 is the only full-sized pick-up that uses a large amount of aluminium in its construction in order to save weight, so an alloy V8 is a perfect marketing fit – and a no-brainer for the Raptor model.

It would also mark Ford’s return to a space currently dominated by rivals General Motors and Dodge/Chrysler, where pushrod V8 engines serve in the engine bays of cars like the Chevrolet Corvette C8 and the Dodge Challenger Hellcat.

The final batch of the original Windsor engines were used in Australia for Tickford’s TS50 and TE50 Falcon AUs in the early part of the 2000s, before the brand switched to more modern V8s, culminating in the debut of the Coyote in 2011.

The Coyote V8 is part of Ford’s Modular engine family, and debuted in the Mustang in 2011.

It received a major overhaul in 2018, moving to direct fuel injection, bigger valves and an increased compression ratio. In Mustang Mach 1 form, it produces 345kW and 556Nm.