UPDATE 02/03/21: While many car manufacturers are struggling through a semiconductor chip shortage forcing long production delays, Hyundai has emerged unfazed by the global issue.

Sources assert, according to Reuters, that the Hyundai Motor Group (including Kia) kept up its purchasing of semiconductor chips last year, while other manufacturers such as Volkswagen, General Motors and Ford all slowed down.

Hyundai even accelerated its purchasing towards the end of 2020, seeing the writing on the wall that chips would become scarce in 2021. This allowed the South Korean motoring giant to build a stockpile of the chips to use in its vehicle production.

“Like other automakers, Hyundai also planned to cut production at the beginning of the year because of COVID-19,” one insider with ties to Hyundai’s purchasing told Reuters.

“But procurement read the trend of the semiconductor industry cutting auto chips production and said, ‘if we don’t buy them as well, we’ll be in trouble later on.’”

Another factor behind Hyundai’s advantage was the relative early success South Korea’s handling of the coronavirus pandemic, which allowed it to get back to making cars sooner, while also procuring a semi-normal run of semiconductors from local suppliers like Korean-based Telechips.

Its stockpile won’t last forever though – a recent Kia earnings call indicated that Kia doesn’t know whether it can weather the next three to six months of diminished supply. That said, it isn’t seeing any immediate production slow-downs like those which have affected other manufacturers.

THE STORY SO FAR

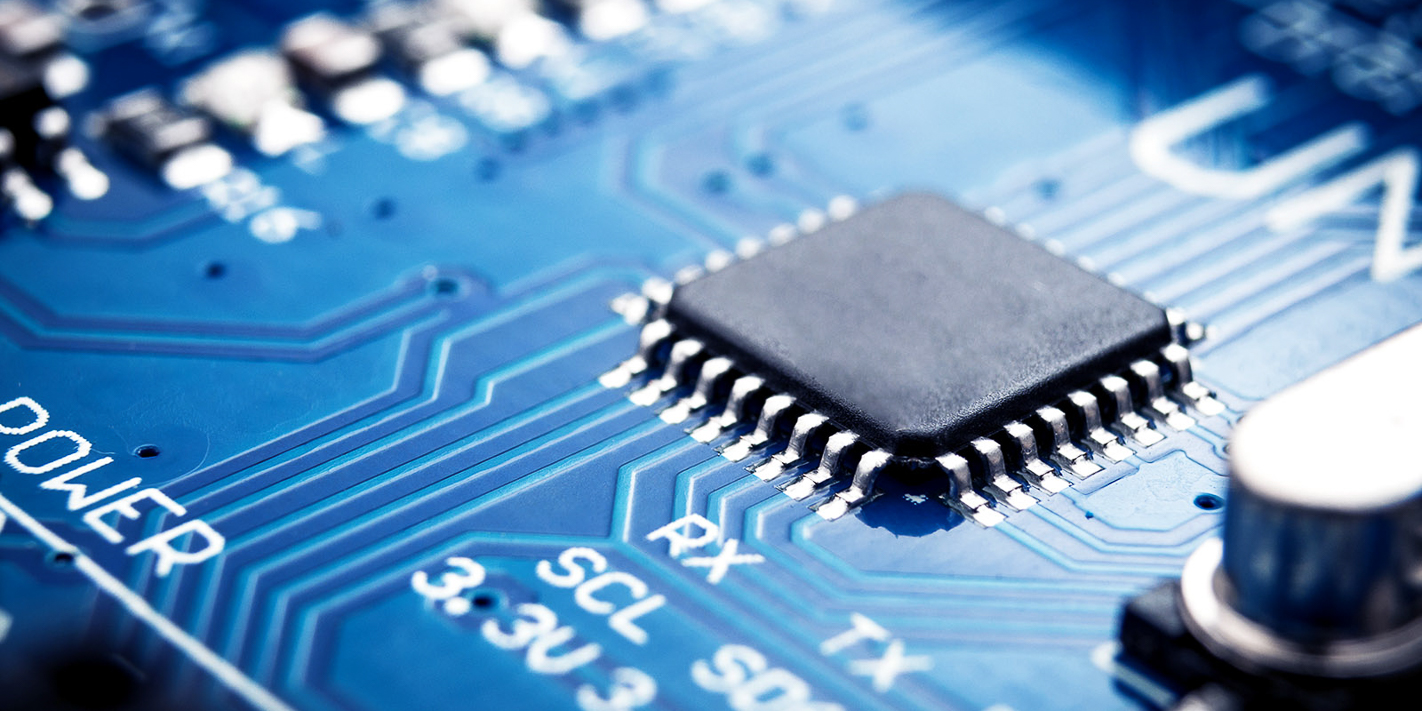

A global shortage of semiconductor chips threatening the auto industry won’t be resolved any time soon, and the pain is set to worsen before it gets better.

Car manufacturers including Volkswagen, General Motors, Ford, Honda, Nissan and Fiat Chrysler have all had their vehicle production lines impacted by the parts shortage, as available chipsets are allocated to personal electronics products over the automotive industry.

Specifically, the world’s chipset manufacturers that ordinarily provide car factories with electronic components are allocating more production to consumer electronics like the popular Playstation 5, personal computers and 5G smartphones.

Autoblog reports the chip industry now prefers the manufacturers of these products because they buy high-end, high-margin semiconductors. Conversely, chips used in cars tend to be of a more basic design.

Traditionally receiving chips on a just-in-time basis, the car industry is now being left out in the cold after shunning the chipset manufacturers last year during the coronavirus-driven car manufacturing downturn.

Rolling coverage of COVID-19’s impact on Australian motorists

Semiconductor makers now realise that there’s demand elsewhere and will no longer bend over backwards to supply demand from global car manufacturers.

As such, Automotive News Europe reports that German auto giant Volkswagen has begun investigating potential litigation and compensation against parts manufacturers Bosch and Continental in retaliation. Daimler has indicated it may follow with its own request for compensation.

Volkswagen has been forced to reduce production in Germany and the United States as a result of the semiconductor bottleneck.

In the long term, it’s expected that relationships between carmakers and chipset manufacturers will heal on the back of electric cars becoming widely adopted.

There is something of a light at the end of the tunnel for carmakers, however: electric, autonomous and high-tech vehicles use more and higher-end semiconductors than combustion-engined cars.

But, in the short term, tensions are set to continue until later this year, according to information provider IHS Markit.

Rather than products becoming more expensive, experts predict car buyers may just have to wait longer for their new car.