Audi is working on a fully synthetic fuel that could allow us to continue using our beloved combustion engines, as an alternative to impending electrification.

What is it?

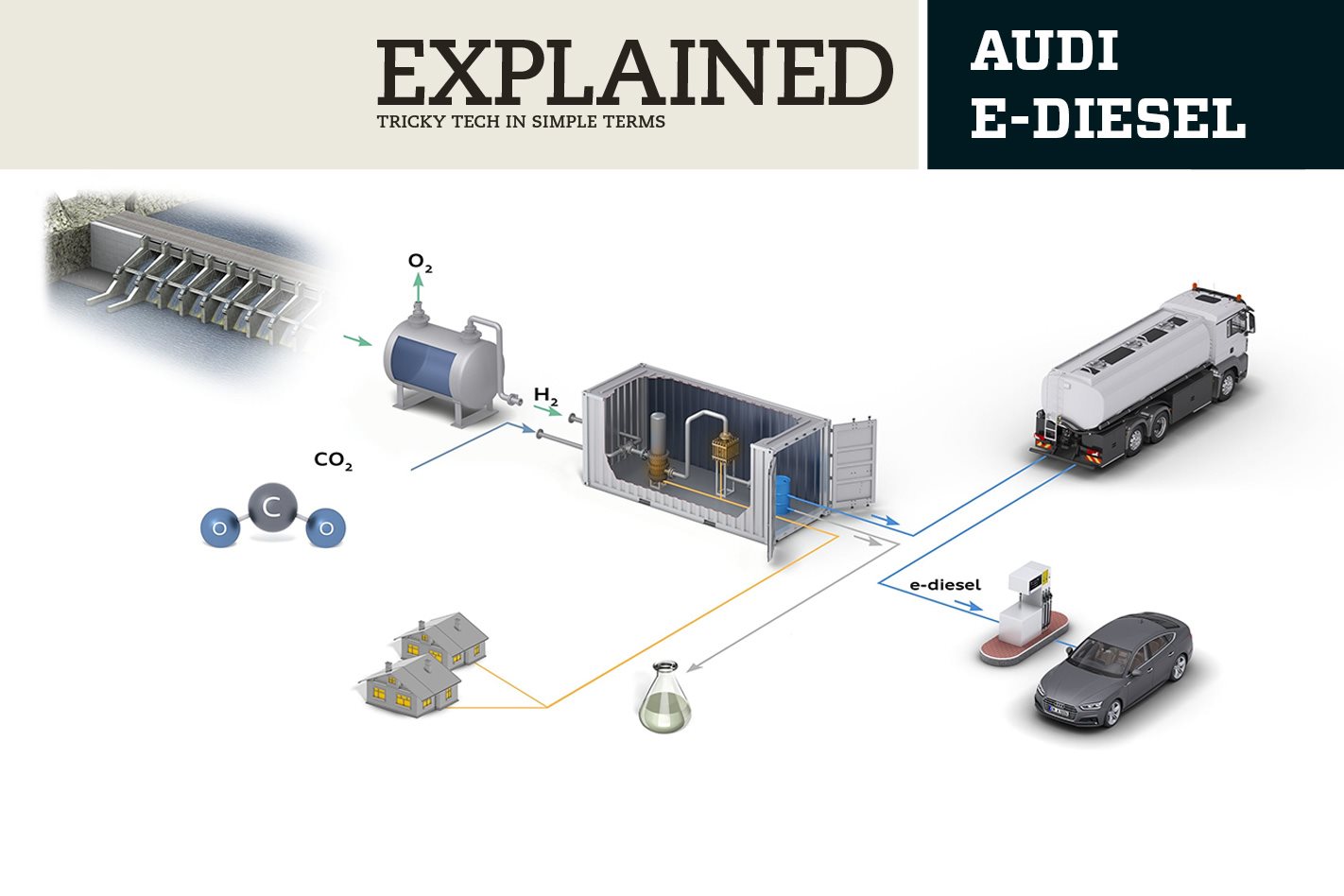

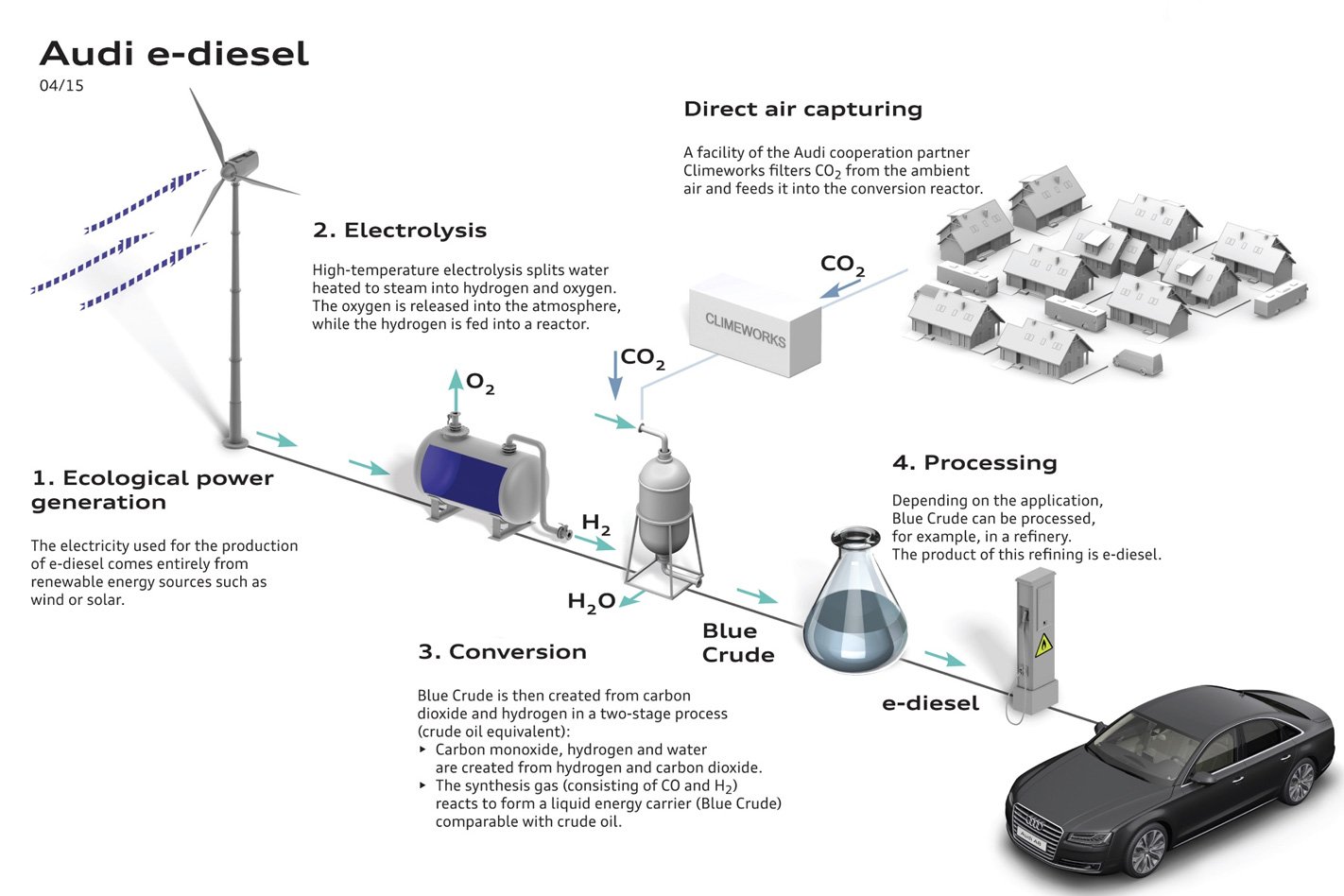

Audi’s latest exploration of combustion engine fuels that don’t rely on petrochemicals sucked from the ground. A pilot factory is being constructed in Switzerland that will produce up to 400,000 litres of e-diesel per year using nothing but renewable energy and water.

How does it work?

When complete, the industrial lab in Laufenburg will use electricity from a neighbouring hydroelectric power station to split water into hydrogen and oxygen. In the second stage of processing, the hydrogen is combined with CO2 that is either extracted from the atmosphere or waste from other industrial processes instead of being released to the environment as a greenhouse gas.

Why does it matter?

Until now, it was largely assumed the only way to break a vehicle’s dependence on fossil fuels was through electrification, but Audi’s completely synthetic fuel allows the continued use of combustion engines without drilling for oil.

Not only does a man-made diesel fuel shake free the shackles of crude oil, the production method is also carbon neutral, which presents the possibility of a diesel-burning Audi with a carbon footprint of zero.

Like any new technology, the first drops of Audimade fuel will be very expensive, but as the operation is upscaled and optimised, the likelihood of finding e-diesel at a bowser increases.

Clever path maize

Audi has already explored the potential of other synthetic fuels. A pilot factory in France and a newer site in Leipzig are turning cornderived glucose into ‘e-benzin’ or synthetic petrol without the need for oil, while other previous projects have created e-gas synthetic methane and e-ethanol.