AUDI has added diesel to the list of fuels it can produce without using a single drop of fossil fuel, with its first batches of e-diesel soon pumping at a pilot facility in Switzerland.

Not only is the process independent of finite oil or other petrochemical sources, up to 400,000 litres of the synthetic diesel will be produced each year using only renewable energy. Like Audi’s other alternative fuel ventures, the e-diesel project previews a future in which internal combustion vehicles are carbon-neutral and free of fossil fuel shackles.

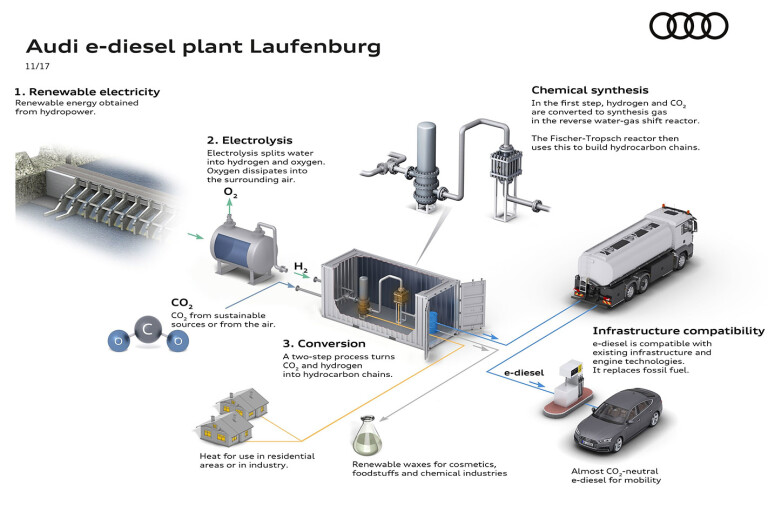

Construction of the industrial lab in Laufenburg will begin early next year in partnership with Ineratec and Energiedienst on the site of a hydroelectric power station - the source of renewable clean energy required in the process.

In the first stage, electricity is used to split water into its constituent hydrogen and oxygen components by electrolysis. For now, the potentially useful oxygen is surplus and released to atmosphere, but the hydrogen is passed on to the second stage of processing.

The most intricate part of the manufacturing is being kept secret for now, but Audi says the hydrogen is combined with CO2 using a reverse water-gas shift reactor to form long-chain hydrocarbons - the basis for liquid hydrocarbon production.

This material is then fed into a Fischer-Tropsch reactor which separates the synthetic diesel. Only part of the hydrocarbon chain can be processed into synthetic diesel but the remaining material also has a use as heavier waxes that are useful in other industries, says Audi.

CO2 provides the essential carbon element for the manufacturing of liquid fuel and can be either grabbed directly from the atmosphere or captured from industrial processes as waste, preventing its release to the atmosphere where it would act as a greenhouse gas.

It appears to be a win, win, win for Audi. While burning fossil fuels releases carbon to the atmosphere that was locked away in oil reserves, Audi’s process takes carbon already present in the atmosphere or from waste applications, while electrolysis adds more oxygen to the environment, and all this from renewable energy.

As if that wasn’t enough, waste heat from the conversion reactor will be piped to nearby industrial and residential areas for heating.

The first e-diesel will be pumped at the Swiss site in 2018 and will be compatible with existing fuel distribution infrastructure and diesel engine technology. As a bonus, its synthetic origin means the fuel contains none of the contaminants found in oil-derived diesel for a higher-quality finished product.

Since 2014, the German car maker has been exploring the possibilities of producing synthetic diesel at another site in Dresden using different technologies, an e-gas research facility in Werlte is producing synthetic methane as an energy source, while a project with French company Global Bioenergies that started in 2015 is already busy making e-benzin synthetic petrol.

COMMENTS