July 2023: 3D-printed Aventador reaches 150th video update

Aventadorable father-son project still going strong

Some five years since we first wrote about it, and nearly two years since he took his audience for a brief drive out of the garage and a tour of niggling issues [↗], this laser physicist and war veteran’s 3D-printed Aventador has come a long way.

? Just five hours ago, ‘Laser’ Sterling Backus posted his 150th clip.

In true reserved Sterling form, the video wastes no time on celebratory antics. Instead, we’re treated to just another update – this time, the priming of the homemade Aventador’s rear end panel.

In fact, how does this channel only have 32,000 subscribers?!

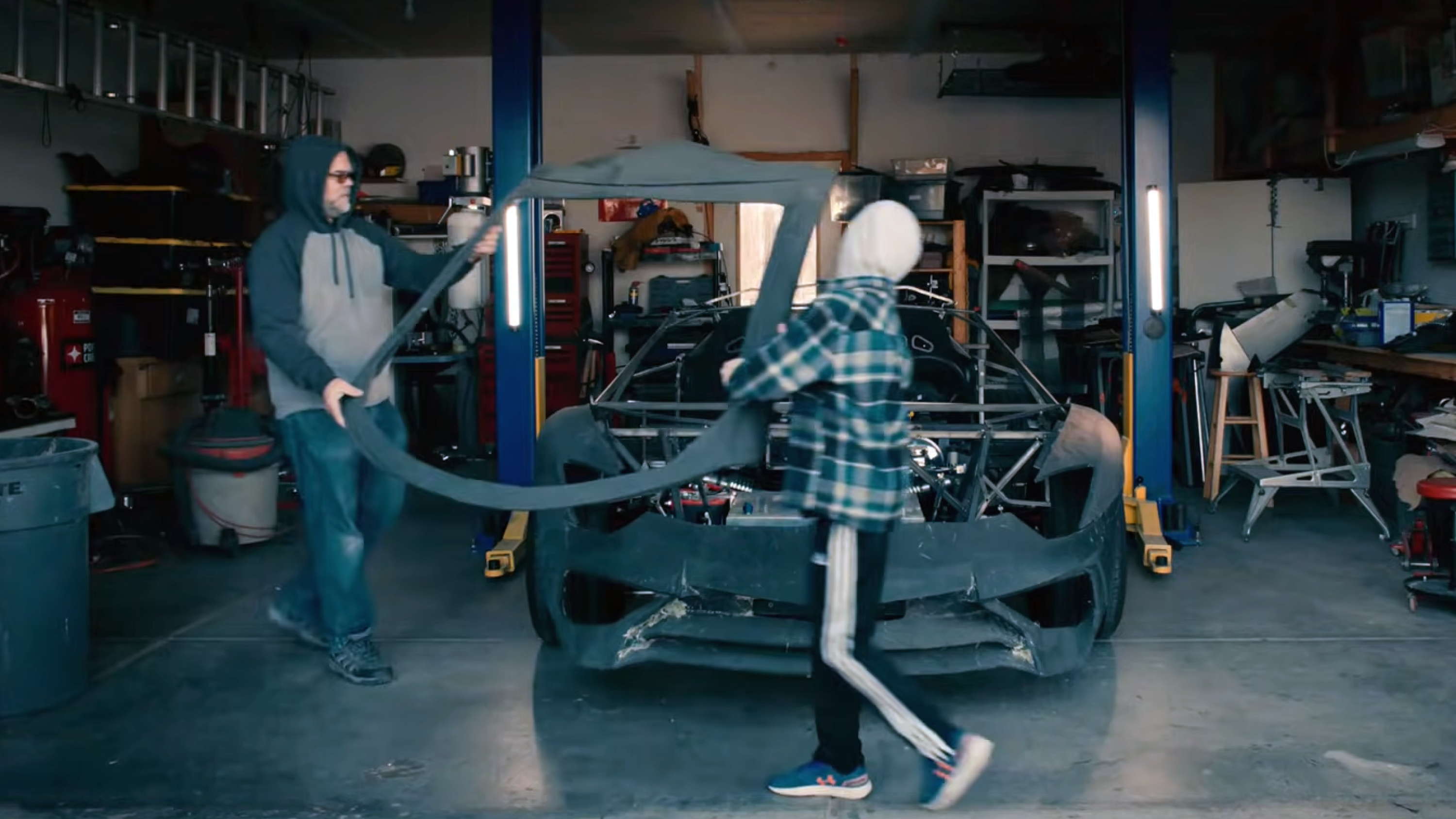

In early 2020 – update 39! – Sterling posted a video of the Aventador growling its way down the driveway with his son Xander (below), but the state of the car showed there was still a lot of work to do.

Then, just one year ago, Sterling posted a video of his 3D-printed Aventador all painted up and out driving down the road – although, in true DIY youtuber fashion, a big chunk of the video is the ‘cameraman’ standing in the driveway waiting for dad to return.

He’s not much for editing, this fella!

As noted further down in this story, the LS1 V8 powering this Aventador – dubbed ‘Interceptor’ – was sourced from a wrecked 2005 Corvette.

Earlier this year, Sterling starred in a great video on YouTube channel 3D Printing Nerd [↗], taking the channel through the work he’s done so far.

Check it out below.

Almost everything about this car is 3D-printed, including the iconic caltrop tail lamps, which we saw in the very first video five years ago [↗].

Go to the other end, however, and Sterling is the lucky recipient of some Lambo-donated, genuine Aventador headlights – normally AU$7000 each as a replacement part from Lamborghini.

The steering wheel is the real deal, too, gifted to Backus when Lamborghini visited.

There are a few other genuine parts in the car, sourced from owners and online sources like eBay, which Sterling details in the video above.

Despite the international attention his project has attracted – including the endorsement of and a visit from Lamborghini – it hasn’t fazed the father of three, who is a research scientist and holds an appointment in the Colorado State University.

“I’ve met new people who are very interested in the project that I’m doing, but besides that, things haven’t changed a whole lot of me, which is good.”

December 2019: Lamborghini sneaks a real Aventador into the garage for a surprise loan

How good is this? That’s the kind of Christmas spirit we love to see from supercar brands. Details linked below.

October 2019: It drives!

It might just be the ultimate backyard project – and now the 3D-printed Lamborghini Aventador lives with a very aggro, if not unusual soundtrack.

In terms of dad of the year, physicist Sterling Backus has the runs on the board after his son dreamed of building one while playing Forza Horizon 3 on an Xbox.

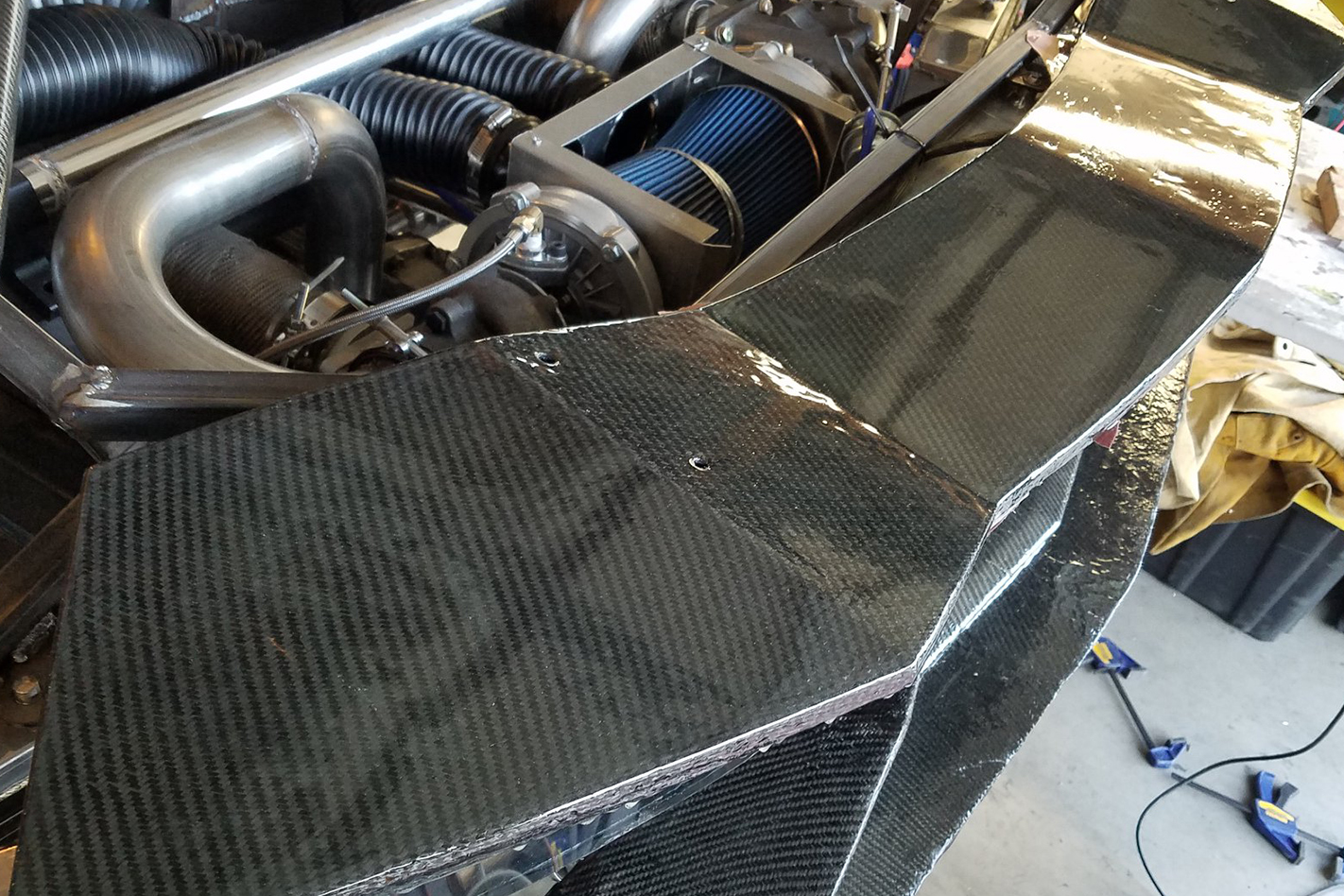

Fast-forward the process and not only has Backus built the frame and 3D-printed the carbonfibre-wrapped panels, but it’s now driveable. And it sounds tough.

Yes, it’s a Lamborghini Aventador, but not as we know it. The V12 has made way for a 5.7-litre bent-eight out of a 2003 Chevrolet Corvette.

However, if you’ve seen this project already, you’d know that it had little chance of remaining standard, with the V8 gaining twin turbos.

You can even see the rear-mounted intercooler’s placement (and bespoke suspension set-up) when the kit-car is driven down the driveway of the family’s home. https://www.youtube.com/watch?v=RMlx6rrdSz4

The howling V12 soundtrack makes way for grumbling booted LS1 overtones. It’s loud, very loud. And it sounds tough, too – if the power figures match the aural menace, then it should be very potent.

Interestingly, the reason for the carbon wrap on the panels is because the 3D-printed plastic melts in the sun if it isn’t protected. That even goes for the scissor doors found on the real Aventador.

Considering the learnings for this project came from trial and error as well as watching YouTube videos, it’s pretty impressive. It’s even on the way to being made roadworthy.

The desire for the end product, apart from enjoying it within the Backus household, is for it to be an educational tool for students.

If you want to follow the build, head to Backus’ YouTube channel. What do you think? Are you tempted to create your own 3D-printed supercar?