Bentley‘s lauded 12-cylinder petrol engine will cease production by April 2024.

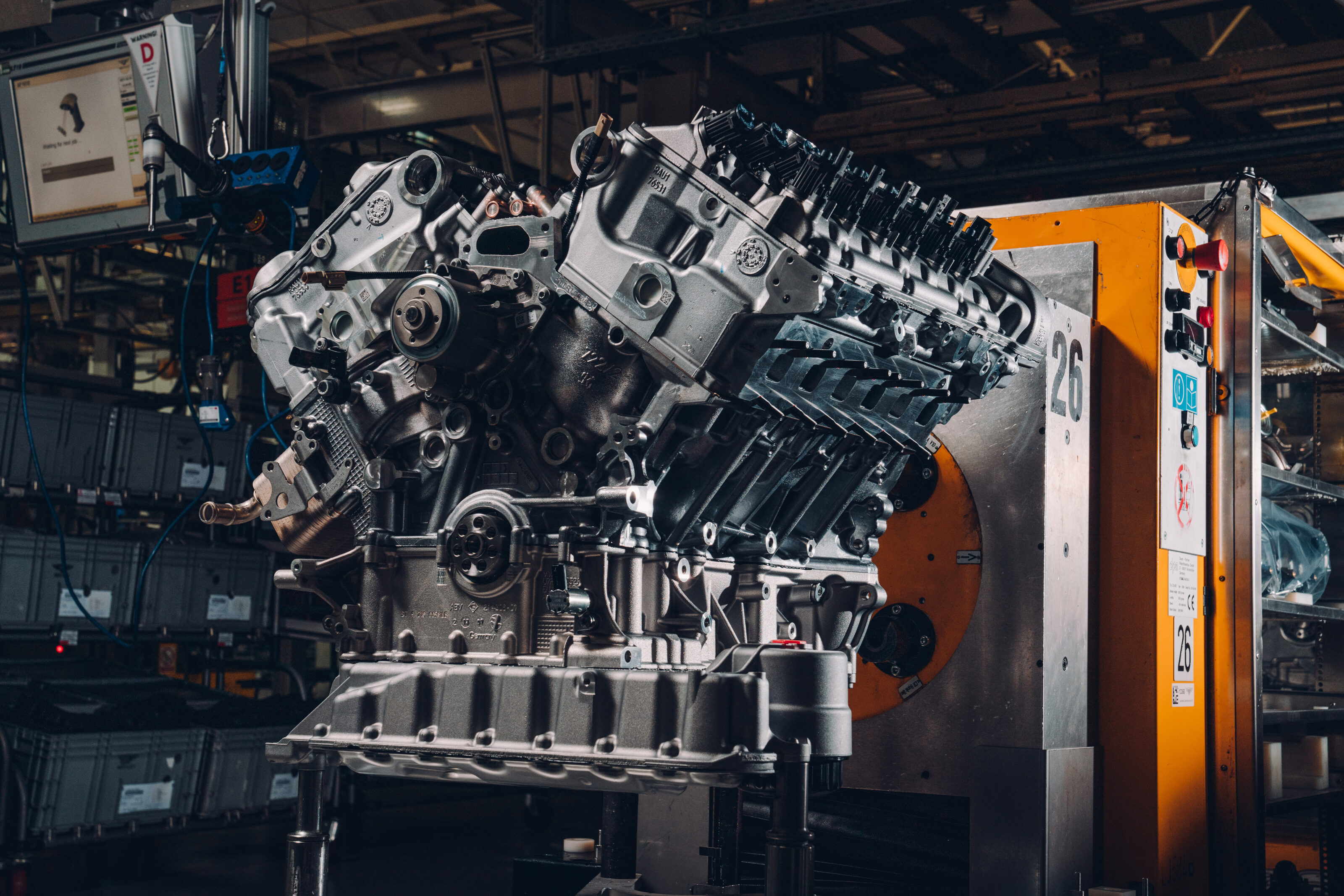

More than 100,000 examples of the 6.0-litre W12 will have been produced by that time, after making its debut on the 2003 Continental GT.

To send off the signature powerplant, Bentley has developed its most powerful iteration yet, turning up the wick to produce 551kW and 1000Nm of torque.

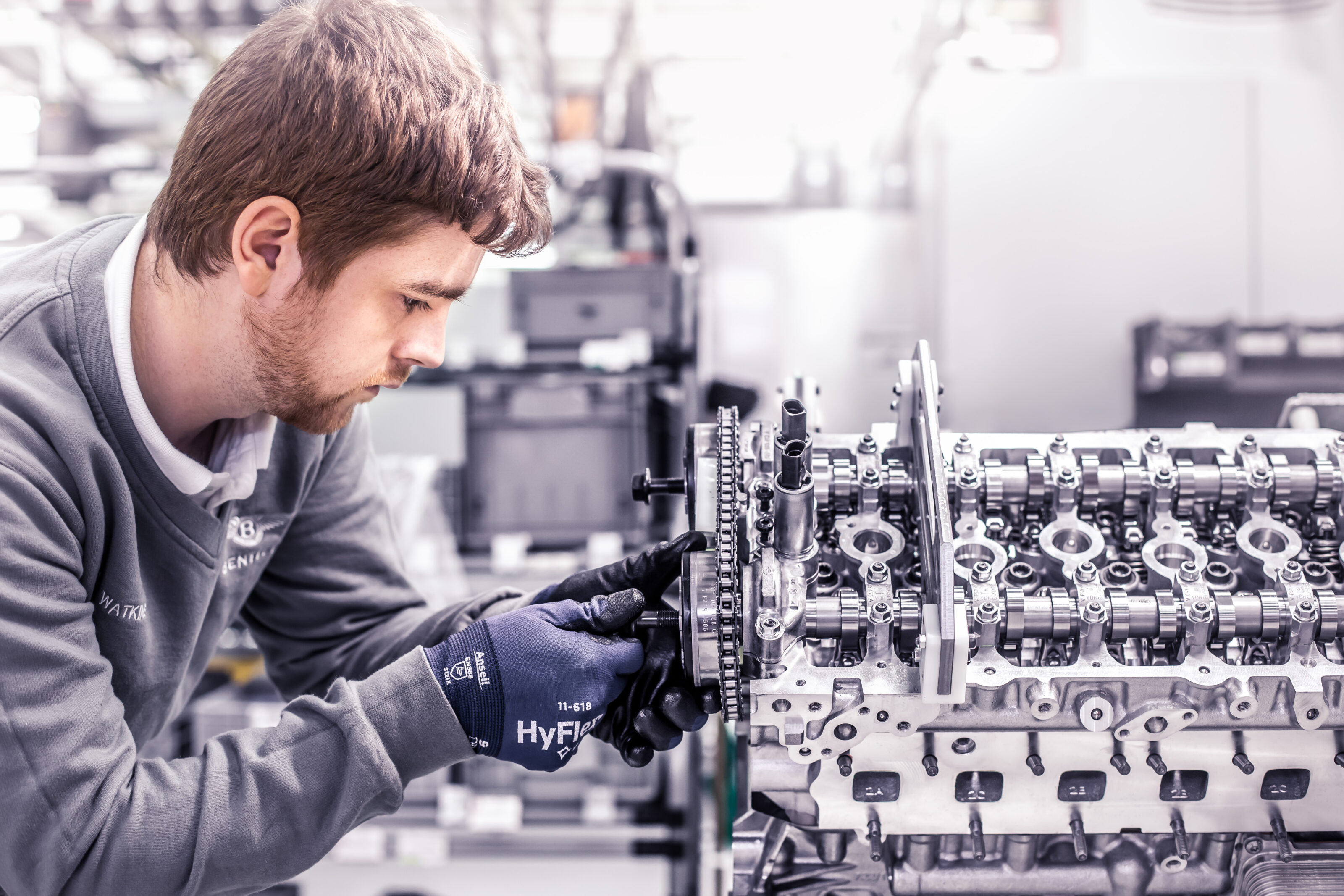

Just 18 of these high-output motors will be crafted by hand, and fitted to Bentley’s ultra-exclusive Batur, built by the brand’s specialist Mulliner coachbuilding department.

The decision comes off the back of Bentley’s accelerated Beyond100 strategy, which will see the brand’s entire model range fully electrified by 2030.

The transition has already begun, with Bentley having introduced hybrid versions of its Bentayga SUV and Flying Spur limousine. After the lights flick out on W12 production next year, Bentley’s entire model line will be offered with a hybridised powertrain.

Adrian Hallmark, Bentley Chairman and Chief Executive, stated: “Our progressive journey towards sustainable luxury mobility means making changes to every area of Bentley Motors.

“When we first launched the W12 back in 2003, we knew we had a mighty engine that would propel both our cars and the brand forward at speed. Twenty years and more than 100,0000 W12s later, the time has come to retire this now-iconic powertrain as we take strides towards electrification – but not without giving it the best send-off possible, with the most powerful version of the engine ever created.”

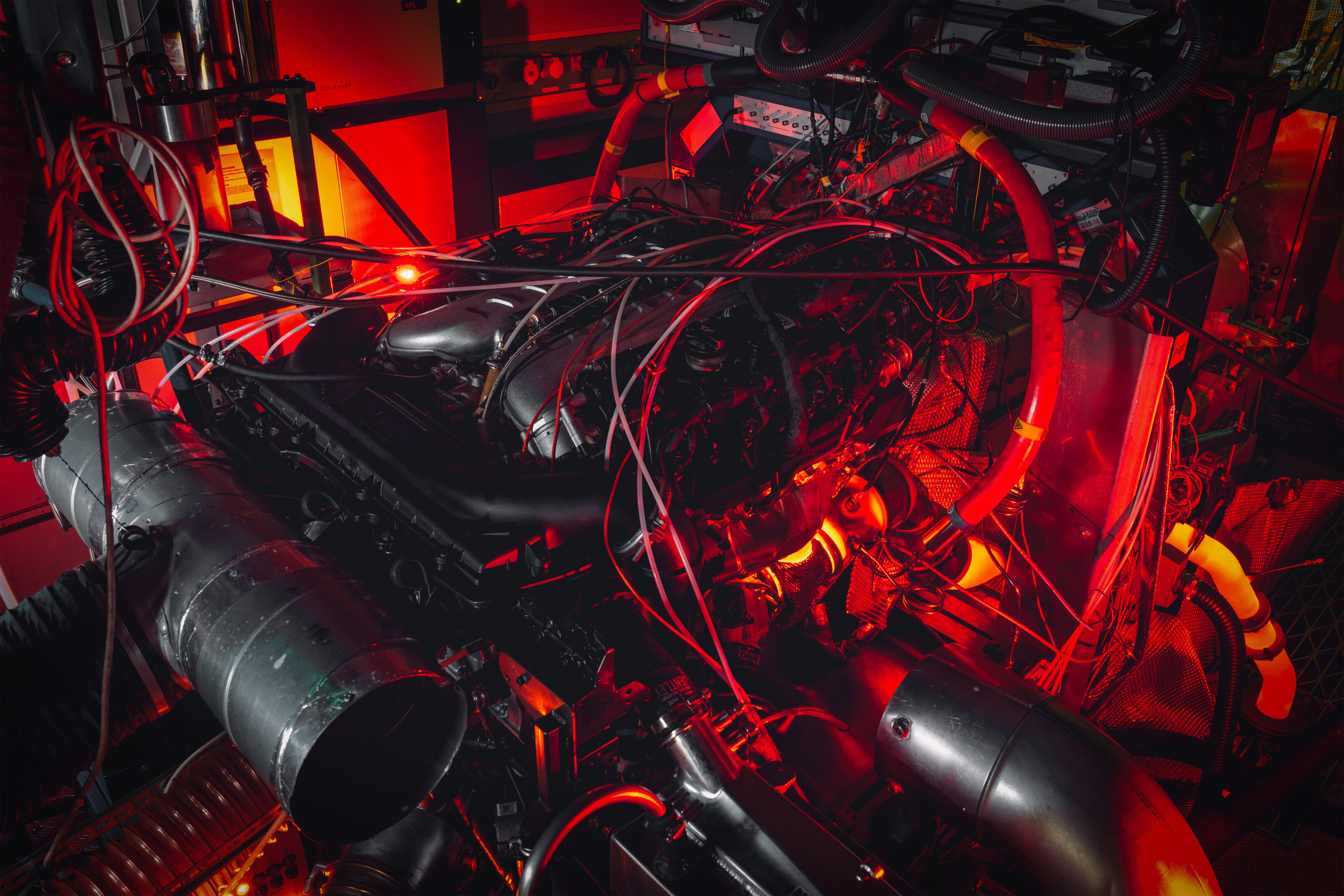

The record-setting outputs from Bentley’s ultimate 6.0-litre W12 were achieved through significant reworks of the engine’s thermodynamics and heat management – with intake, exhaust and cooling systems all massaged for increased efficiency and performance.

The turbocharger compressors are a new, more efficient design and are fed by air intakes which have been enlarged by 33 per cent.

The 6.0-litre’s sizeable charger air coolers have been thickened by 10 millimetres and house a redesigned core that rejects 35 per cent more heat from the pressurised intake air, reducing intake temperatures and a subsequent denser air charge resulting in more power from the turbos.

The big unit’s freer-breathing ‘cold side’ has been met with revised engine and gearbox calibrations to optimise delivery of the increased torque and power loads, enhancing the exclusive Batur’s driving experience.

Each W12 engine is hand-assembled by a specialist team of 30 at Bentley’s Pym Lane factory in the brand’s historic home of Crewe, England, over the course of 6.5 hours.

Bentley states that its aim is to retrain and redeploy all 30 craftsmen elsewhere in the business, while the W12 engine facility will make way for expanded production lines of Bentley’s plug-in hybrid 3.0-litre twin-turbo V6.

Sadly, all 18 examples of the 551kW Bentley Batur have sold out, but Bentley’s 6.0-litre W12 can still be ordered in 484kW guise in the Continental GT Speed, Bentayga Speed and Flying Spur Speed, and can also be specified in special Mulliner-made examples of the Continental GT and Flying Spur. These will be the final series production vehicles fitted with Bentley’s ubiquitous 6.0-litre W12.

Under mounting societal and environmental pressures, such large capacity engines with double-digit cylinder counts are becoming increasingly endangered, and less favoured in comparison to the benefits of electric augmentation and developments in the turbocharging arena.

After Bentley’s W12 bows out next year, the likes of Aston Martin, Ferrari, Lamborghini, Mercedes-Maybach and Rolls-Royce will be among the last 12-cylinder stalwarts in the Australian market.

We recommend

-

News

News2023 Bentley Continental GT Mulliner W12 revealed

Bentley has tweaked the plush Continental GT Mulliner, adding the Speed’s more-powerful W12 powertrain

-

News

News2017 Bentley Flying Spur W12 S revealed

Fastest ever Benter sedan breaks 321km/h

-

Reviews

Reviews2019 Bentley Continental GT W12 review

Bentley's big and brutish coupe returns, ready to show the rest of the world what a Grand Tourer should look like