Launching a new vehicle in to nearly 200 markets for a global carmaker is riddled with complexities, challenges and downright hard work.

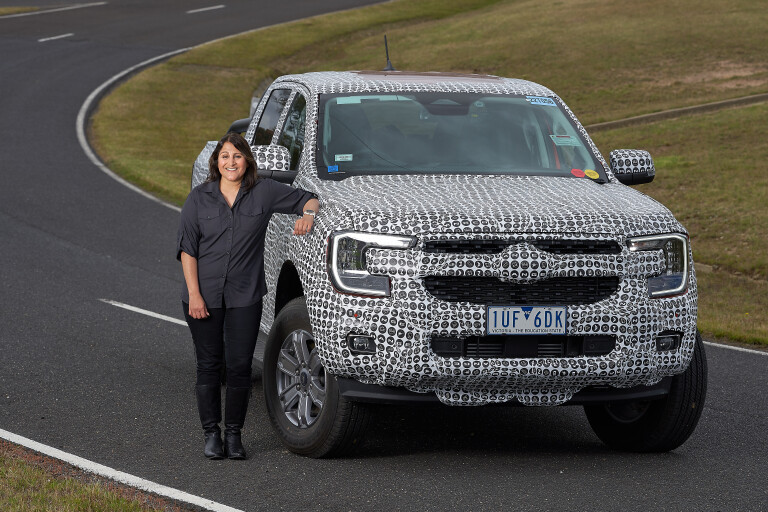

Supreme engineering talent is not enough; being a great people person alone won’t do the job. It’s a unique skill set that sees T6 global program manager Pritika Maharaj ensuring Ford’s Ranger and Everest are built to the demanded quality standard, with the right powertrains, capability and features – to a strict schedule. Watching the T6 line-up roll out around the world is her moment of truth.

“It’s tricky, but I wouldn’t call it the hardest time,” Maharaj tells 4X4 Australia. “I quite enjoy launch; I like it when it’s all about delivery and executing right. I wouldn’t say it’s harder, but certainly it’s more immediate and there’s a lot more immediate pressure because you’ve got to turn things around quickly, you’ve got to think quickly, get the right people engaged. A lot of what I do is trying to make sure that those people are engaged and that they understand the urgency, move fast and resolve what we need to.”

Maharaj is talking about what’s going on at Ford across the globe as T6 rolls out in the coming months. The big decisions, which include the broader program goal, were determined years ago, but as the plan unfolds it’s her job to sort any stifling issues or challenges that may put the team – and the final product – off course. Maharaj’s job title as T6 program manager is as literal as they come, she says.

“I spend a lot of time in what we call ‘change management’, which is where we review any changes that the engineering team want to make. We review them and either approve or reject,” Pritika explains, suggesting that it doesn’t mean the competing engineering teams are always buying her lunch.

“Quite the opposite! It’s all about making sure we get the vehicles on time and with quality, so anything that pops up along the way, and it may not be only an engineering issue; it may be a supply issue; it may be a supplier having trouble with a certain part or logistics – it could be anything.”

Again, literally anything: manufacturing challenges, factory logistics, currency fluctuations or global pandemics. “Anything that is important to delivering Ranger, Everest and Raptor on time and with quality comes under my remit. So most of the day I spend time working on managing and making sure that all of our deliverables are tracking to the plan and that we’re in support and ready to go.”

Early years

Part engineer, part people-person, part logistics, completely whatever it takes, it’s a serious accomplishment to deliver a program – across any brand, and any segment – but for Ford in Australia, the T6 is its breadwinner.

This underlines how critical Maharaj’s role is to the brand in this country and its standing with the global Ford ecosystem. It’s a gig that a young girl growing up in North Balwyn in Melbourne reached through curiosity, tenacity and talent.

“When I was really young, I enjoyed pulling things apart,” Maharaj explains. “Mum wasn’t the kind of mum that said, ‘Girls do this and boys do that’, but rather, ‘Whatever’s your interest let’s go down that path’.”

That saw Pritika’s mum gift her a Meccano set – the classic French kit made of metal, not plastic – which sparked an inquisitive young mind.

“That’s where it started: just tinkering, playing and building,” she says. “I have a bit of an analytical brain and I like to work out how things operate and what makes them go, whether it be a person or a mechanical system.”

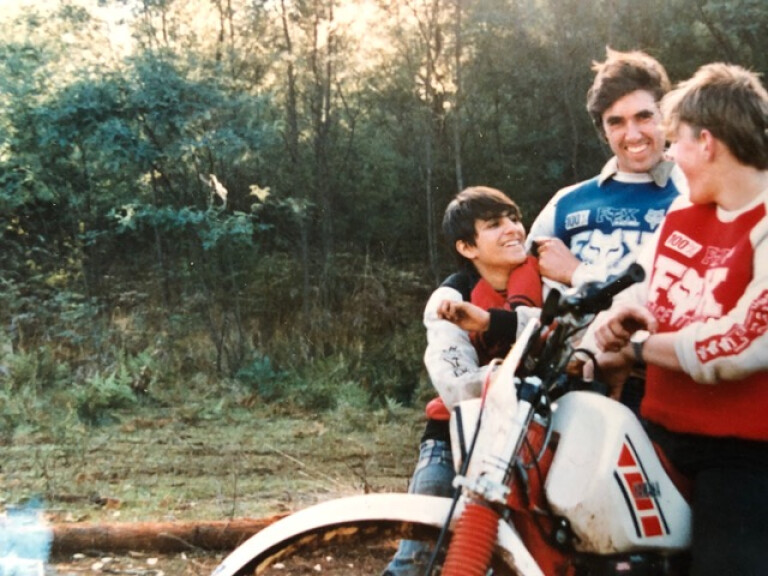

That interest was apparent on trips with family friends to the Strathbogie Ranges in Central Victoria, where her mechanical mind-mapping developed. Every Easter, Maharaj’s family would head there and camp with other families on a large property.

“That was when I first got to ride a motorbike,” Pritika says. “It was just an old clanger. I had a bit of a go, and I got the bug from there. After that, I started saving and I ended up buying myself a YZ80, the last of the air-cooled ones, and I started just mucking around.”

The problem was where to ride the Yamaha back home in Melbourne.

“We had an area behind our house where you weren’t actually legally meant to ride but you could get away with it and just had to be quick if the police came!” Pritika laughs. “So I just used to fang around there, and I got to meet other people that were keen on the same sorts of things.”

Carrying out mechanical work on her bike, tuning the suspension and figuring out how to go faster only solidified Maharaj’s passion for working out what made things tick. She decided to discover as much as she could, vehemently focussed on her goals. That led to her first part-time job while still at school.

“I just wanted to learn more. School may’ve offered some kind of 101 in mechanics just to teach you the basics; how to service a car, the oil, those really simple things. So I got interested then, and we had a local garage, so I went up there one day and said, ‘Look, I’d love to work here part-time, just interested in anything, I don’t mind what I do, I just want to learn – would you consider giving me a job?’”

It wasn’t an instant success when approaching the owner, Alan, for a start, especially when men dominated the staff there. Yet Pritika wasn’t fazed.

“I might’ve had to hound him a couple of times to get him, but basically he was a really great guy and agreed to let me work after school and also Saturday mornings. I started off really very basic: initially they’d let me fill customer cars, check oil and water and pump the tyres and that sort of thing, and then as I got to know the team and they got to know me, I got to progress along, so I moved in to doing basic services.”

An epiphany

Pritika’s knowledge grew, again only stirring her to know more. Learning from the mechanics she worked alongside, the next milestone was an apprenticeship. The gutsy teenage Maharaj went back to Alan to see if he would support such a move.

“He said yes, but only if I finished my schooling,” Pritika says. That proved a sliding door moment for her.

“I finished school and by then I’d had a number of years in that learning environment. I’d had a good opportunity to work in the garage, but I could also then see that maybe I’d be keen to learn a bit more about how it all works and be involved in engineering and designing.”

That saw Pritika go on to engineering at the Royal Melbourne Institute of Technology (RMIT) – but continue tinkering. “I also got in to racing. The interest in motorbikes, the interest in mechanics, it was really the next step,” she says.

There was no holding her back – and she had full support from her parents, her father, a gynaecologist, her mother a research fellow at the Victorian Institute of Strategic Economic Studies.

“Nothing to do with cars, and they were never interested in cars or bikes or anything like that … I talk about my mum being fierce, she was fiercely independent and very much ‘you can do anything you want to do’. I got that from my mum. From my dad, he was always looking for ‘How can you do better?’. We always joked that you’d bring an assignment home and be so pleased, but dad would always be looking to see, ‘Well, could you have done any better?’ type thing, and that was a little tough at times, but it also meant that it’s kind of who I am now.”

The adventure had shifted the goal posts, which saw Pritika join Ford to work in powertrains, fiercely independent yet with her dad’s ‘how can you do it better’ ethos framing her work.

“As a kid it was about being a president of a company or something – but once I was at Ford and I was working in engine design, I was surrounded by so much experience. We had some really brilliant engineers in terms of engine engineers, so I went in to that team and was surrounded by all this intellect and experience, and at that point I wanted to be like those guys – there was Alex Mishura, Ken Stanford, Tony Boot – they were amazing; the knowledge between them, and that’s what I wanted to do, I wanted to become a technical guru or specialist on engines.”

Pritika worked on the legendary Ford in-line six, developing the Aussie-first liquid-phase injection (LPI) version for the FG Falcon, as well as developing an enduring crank design for the I6 that was never bettered.

“It had so many elements, and it doesn’t sound complex, but it is – there’s a lot to the crankshaft in terms of its design, there’s a lot of work a crankshaft has to do to deliver refinement and performance. When we finished the I6 engine, that crankshaft remained, so from the time I engineered it right through, it survived, and that really makes me smile and feel proud.”

The T6 call

That progress led to Maharaj’s regional role as the new Ranger, Everest and Ranger Raptor hit not only Aussie showrooms, but saw factories around the world ‘switched on’ as production kicks off. Any last-minute issues are about getting the right people in the room and making a rapid, effective call – that call’s on Pritika and her team.

That makes the rollout of the updated T6 models a unique and special time. “You have to ask so many questions, because, depending on which plant we’re talking about, at the moment we’re obviously in the middle of launch and ramp up for Thailand plants, so it’s all about stability now and trying to minimise change for only things that we absolutely must do, and a lot of that will come from the plant as they ramp up in to volume.

“They might hit some obstacles and they might reach out for help, and it’s really just trying to work out right, we don’t really want to change too much now, but it’s really important to support the quality execution and just try to sift through that; whereas, when you’re talking about some of our other programs, other plants that are yet to get to that point, then there is other general engineering change and work to be done as we progress.”

That mix of people management and technical knowhow is rewarding for Pritika as the new models roll out. She describes herself as very direct in her approach and won’t simply congratulate the team if the work isn’t what’s required; that can be a difficult challenge.

“You need to be very focussed and mindful about what motivates and how to get the best out of people, but at the same time, you’re right in the middle of launching a product and delivering a program so there’s a lot of good, technical interesting things to get stuck in to along the way. So I’m very strong on wanting to be honest, I don’t like to, you know, give people fluff and nonsense and just tell them, ‘Great job, keep going’, I’m not at all from that kind of school – I’d much rather honesty.”

The introduction of V6 powertrains to the new Ranger and Everest line-ups is close to Maharaj’s heart, especially given her beginnings with Ford in engine design. She believes that there’s plenty of life left yet in internal combustion despite the popularisation of EVs. Regardless of what’s fashionable, the T6 team goals, she says, are always customer driven.

“At the end of the day I really want to deliver the best that I can or be part of the best delivering team. I love engineering, but what makes it all real are the people. That’s what really drives me. The next-gen T6 has absolutely been a dream experience because, and I mean this genuinely, working with people sharing a common goal, which is to deliver for our customers, is just a really dynamic, exciting successful environment to be operating in.”

Director's cut

Given the intimate knowledge of the T6 models arriving in showrooms this year, what would the program director park in her own garage? It’s no surprise, really.

“The Raptor – it’s going to have the performance and also the off-road capability. Now that I don’t race on the motorbike, I’ve got to look for the adrenaline elsewhere, so off-roading is a lot of fun. The Raptor’s going to be a pretty awesome beast off road. Initially I’m going to get in to a Wildtrak with a V6, so that will be a good start, but eventually it will be a Raptor.”

Why a Wildtrak to start? Customers will have first preference, even over the team that created it.

On the bike

Pritika’s early years with her Yamaha YZ80 weren’t short-lived: they were merely the beginning.

“When I finished engineering, I started racing a 125 GP bike, and we had to play with the suspension to get it set up, especially for my weight and my size cause I’m not super tall and at that stage I was quite light – so there was quite a bit of tuning, and I had some fantastic help from experienced racers that helped me along the way,” she says.

“The engine was fascinating, and it was so simple. You’re talking about a single-cylinder; what I loved was working on getting as much performance as you could out of it. The reason I like engines is that I like engineering, but I also like going fast, so it’s a natural combination if you like – that speed and mechanics.”

COMMENTS