IT STARTED with a squeak. Many thousands of kays ago the 2011 VDJ78R developed a small squeak from where the clutch fork rides on the pivot ball. It was initially ignored, replaced by turning the radio up.

However, the cacophony coming from the mighty Troopy every time the clutch lifted became too much to ignore – there’s only so far you can free-roll with your foot on the clutch. The annoyingly squeaky part wouldn’t cost much to repair or replace, but the whole gearbox needed to be removed to get to it.

The Troopy only had about 60,000km, but with the gearbox out it seemed appropriate to slot in a new clutch; and, just to lighten the wallet further, it also seemed the right time to change the fifth gear ratio to help with long-distance mile munching.

There was a fair amount of procrastination in the ensuing months about the type of clutch to use, as well as whether or not to re-gear the box via one of two methods.

Clutch

OTHER than wanting a heavier-duty clutch with a higher clamping pressure, the major concern was to end up with a foot pedal that wasn’t too heavy or too hard to push in. Many questions thrown at sales staff, owners and anyone else that has ever owned an aftermarket clutch returned mixed answers as to the pedal feel and useability of clutches.

The clutch needed to be easy to use in a daily-driven vehicle (both on- and off-road) and be able to be slipped if needed (even though it’s not good for them) and not take up in an instant.

While the V8 diesel only has a moderate power upgrade via a chip and exhaust, the standard clutches are well-known for not handling too much of a power increase without slipping – this one was slipping slightly, most notably while taking off from a start and towing. It required extra clamping pressure to help handle towing camper trailers and caravans, as well as any future (higher) power upgrades to be thrown at it.

The long search led to NPC Performance Clutches, which manufactures a massive 1300Nm clamping pressure plate and replaces the OE flywheel with its own custom 10-inch billet-steel flywheel unit to achieve superior figures.

The pressure achieved at the pressure plate fingers is 1300Nm, so the clutch can theoretically handle a twisting pressure (force or torque) of 1300Nm. Comparatively the standard clutch and pressure plate only have to hold back 430Nm of force from the standard engine. That means the NPC unit has roughly three times the amount of clamping pressure than OE.

Some people suggested this was overkill and too expensive, but you’re getting a new custom flywheel to suit the clutch and pressure plate. Right from the get-go the pedal felt slightly lighter than the standard feel, and that easy pedal pushing, combined with the ease of use (it can be slipped if needed) and massive extra clamping pressure, has proven it was worth the extra cash.

Box re-gear

FIFTH gears on pre-2017 V8 70 Series Cruisers are notoriously short, returning a relatively high-revving and loud long-distance highway drive experience. In 2017, Toyota saw fit to change the 70 Series box ratios of second and fifth cogs by seven and 15 per cent respectively.

A later model (than the 2011 Troopy) box could’ve done the job, but there was little reason to change second gear, as it was already low enough and useable enough for towing and general off-road work.

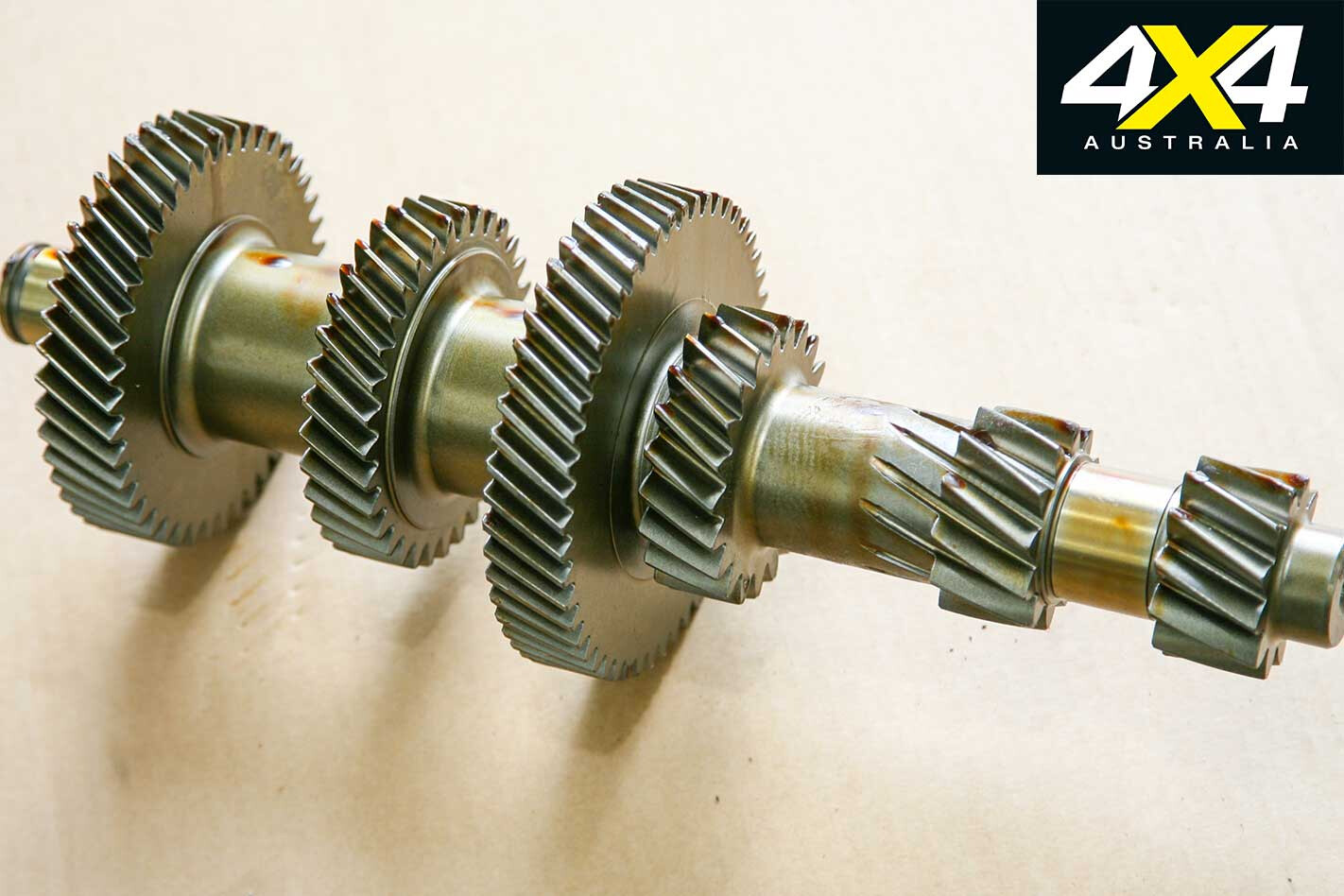

Enter Terrain Tamer’s modified ratio gear set kit, which leaves second as standard but changes fifth gear by more than 20 per cent. The complete gear set is a one-piece unit comprising first to fifth, plus reverse cogs, and it’s manufactured in Japan utilising hardened steel with a Rockwell rating of 62 – that means it’s damn hard and of high quality.

A gearbox mob pulled down the old ’box and stuffed it full of the new Terrain Tamer kit, which effectively changed fifth cog from 0.881 to 0.736 to provide a theoretical change of about 400rpm. That 400rpm may seem like a minimal drop, but the long-term fuel savings will have a positive impact on the bank balance.

The noise difference makes it worth it, too; given 70 Series are commercial vehicles with little to no soundproofing as standard. Obviously this lowering of revs can’t ever convert the Troopy to a 200 Series luxo-barge, but it has helped considerably.

The downsides: any upping of gear ratios puts more stress on the driveline, with the potential over-gearing making the engine labour.

This can cause higher fuel usage and less ability to use that higher gear-set if the engine can’t deliver enough torque at the right revs. Given the LC has a DP Chip that can be turned off, the engine could be tested close to standard (other than the three-inch Taipan XP exhaust system and 33-inch rubber). Indeed, the engine struggled slightly on long and steeper hills, on the highway at 100km/h and 110km/h.

There were occasions when a downshift to fourth was required, which wasn’t the case with standard gearing where fifth was capable. With the DP Chip turned back on and set at position three (which was deemed safe and reliable via the installer), to return 131kW and 747.5Nm, there was little need to fiddle with the gearstick over the same roads.

Towing a camper or caravan would need more downshifting than normal, and that’s where even higher returns of safe tuning will help. That leaves you with a taller fifth that can be used most of the time, but with the occasional downshift to prevent labouring.

While the mods mightn’t pay for themselves for a very long time, the pleasure and security of a quieter cabin via the lower revving engine, as well as a huge clamping pressure clutch with soft feeling pedal, was well worth it.

To date, since fitting the fifth gear upgrade and driven almost 3000km, I’ve managed a fuel consumption average of 13.6L/100km from the big Troopy. While nothing fantastic, what is surprising is that it’s a full 1.0 to 1.5L/100km better than I’ve ever achieved prior to the change. That driving has been predominantly at highway speeds (100 to 110km/h) making most use of the fifth gear change.

Obviously, the more it can be used (at highway speeds), the more savings you’ll achieve. Lower speed driving in lower gears will make no difference, neither will 4x4ing.

Geared down

Standard gearing in my Troopy saw it clocking 2200rpm at 100km/h and 2500rpm at 110km/h; compared to the Terrain Tamer kit returning just 1800 and 2100rpm at 100 and 110km/h. That confirms the theoretical reduction of 400rpm.